04 Nov A Complete Guide to Choosing Fiber Cement Board for Exterior Wall Projects

Table of Contents

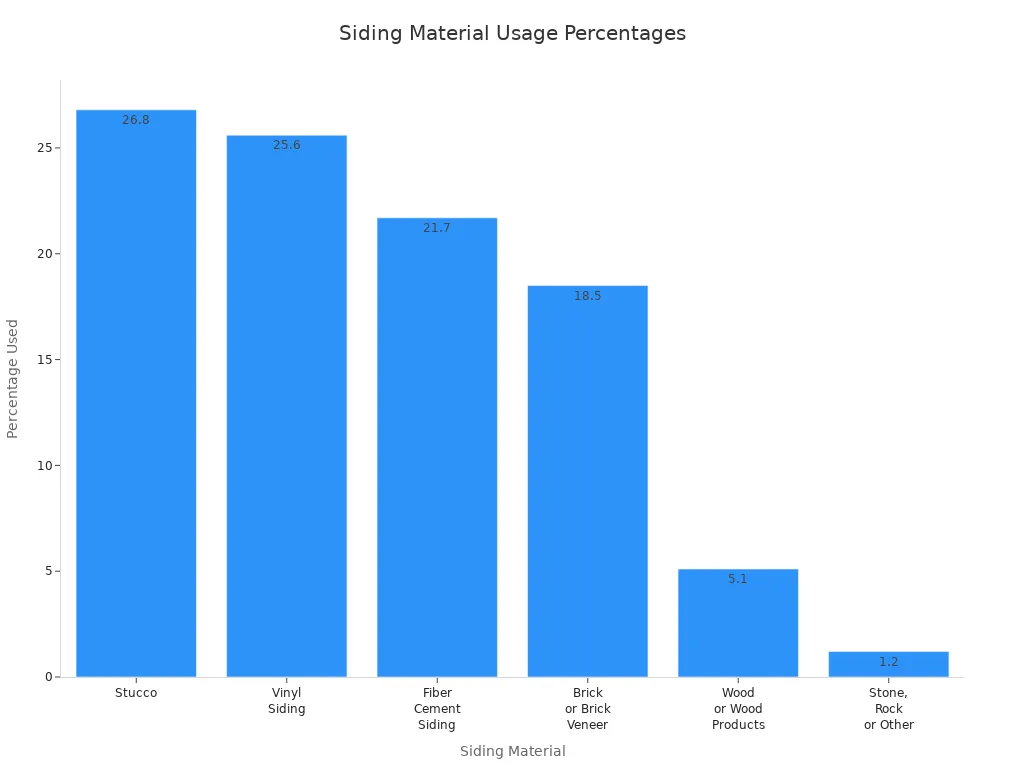

When selecting the best fiber cement board for exterior walls, it’s important to choose boards that are durable, have solid certifications, and are cost-effective. Many builders prefer fiber cement board for exterior walls due to its long-lasting nature. It is fire-resistant and requires minimal maintenance. According to the chart below, 21.7% of exterior wall projects utilize fiber cement siding, making it a leading option.

Refer to the table below to understand the key factors to consider when making your selection:

Factor | Description |

|---|---|

Durability | Fiber cement boards for exterior walls are known for their longevity, making them a reliable choice. |

Fire Resistance | These boards are non-combustible and comply with fire safety regulations, which is crucial for larger projects. |

Low Maintenance | They require minimal upkeep, leading to cost savings over time. |

Aesthetic Versatility | Available in a variety of styles and finishes, they can complement different architectural designs. |

Sustainability | Fiber cement boards contribute to green building certifications like LEED or BREEAM, appealing to environmentally conscious individuals. |

Acoustic and Thermal Performance | They effectively insulate against noise and heat, enhancing comfort in urban settings. |

Additionally, consider your local climate, the level of maintenance you are willing to commit to, and the brands that are recommended by industry experts.

Key Takeaways

Pick fiber cement board because it is very strong. It can last more than 50 years. This makes it a good choice for outside walls.

Check for fire resistance labels. Fiber cement board does not burn. It helps keep you safe in places with fire risk.

Choose the type that fits your needs best. Standard boards let you change how they look. Pre-finished boards are faster to put up.

Think about your local weather when picking a board. Some weather needs special features for the best results.

Take care of your siding often. Clean it once a year. Check for any damage to keep it looking good and lasting long.

Fiber Cement Board for Exterior Wall

What Is Fiber Cement Board

You might ask why fiber cement board is so popular. This material mixes a few main parts to make it strong. Each part helps the board work well. The table below shows what is inside fiber cement board and how each part helps:

Component | Contribution to Performance |

|---|---|

Cement | Gives the board strength and helps it last long. It also helps the board resist water and fire. |

Cellulose Fibers | Makes the board tough and flexible. These fibers also help the board be better for the environment. |

Silica | Fills in spaces to make the board dense. It helps stop the board from warping or shrinking. |

Cement makes the board strong and keeps out water and fire. Cellulose fibers help the board bend without breaking and are good for green building. Silica fills gaps and keeps the board from changing shape. When you pick fiber cement board, you get something that lasts through daily use.

Why Use for Exterior Walls

You want your house or building to last and look nice. Fiber cement board has many benefits over wood or vinyl siding. Here are some reasons to use it on your outside walls:

It does not rot or get eaten by termites. It stands up to bad weather and can last more than 30 years.

The board will not burn, so it is safer than vinyl siding.

You do not have to spend much time or money to keep it clean. Just wash it with soap and water sometimes.

Fiber cement siding comes in many colors and styles. You can pick what looks best for your home. It is also a good choice if you care about the planet because it uses eco-friendly materials.

Benefits of Fiber Cement Siding

Durability and Longevity

Durability and Longevity

If you pick fiber cement siding, your building will stay strong for a long time. This siding acts like a tough shield for your house or business. It can last for many years, even when the weather is rough. Here are some facts about how long it lasts:

Fiber cement siding can last over 60 years, depending on the brand.

It lasts more than twice as long as wood siding.

When installed and cared for, it usually lasts over 50 years.

Some brands, like James Hardie, give up to 30-year limited warranties.

Fiber cement siding can last from 50 to 100 years, which is longer than most other siding choices.

Fiber cement siding is very tough. It can handle hits better than composite siding. Bugs, fire, and rot are not a problem for it. This makes it a good choice if you want siding that will last. You can count on it for your next project if you want something strong.

Weather and Fire Resistance

You want siding that keeps your building safe from bad weather and fire. Fiber cement siding does this job well. In places like Florida, where storms and rain happen a lot, people say fiber cement siding stays in good shape. It does not bend or rot, even with lots of rain or snow. Hardie fiber cement siding passes tests for sun, snow, and heat, so it works in every season.

Fiber cement siding does not get water damage, so it does not bend or rot.

It stays strong and looks good, even after storms.

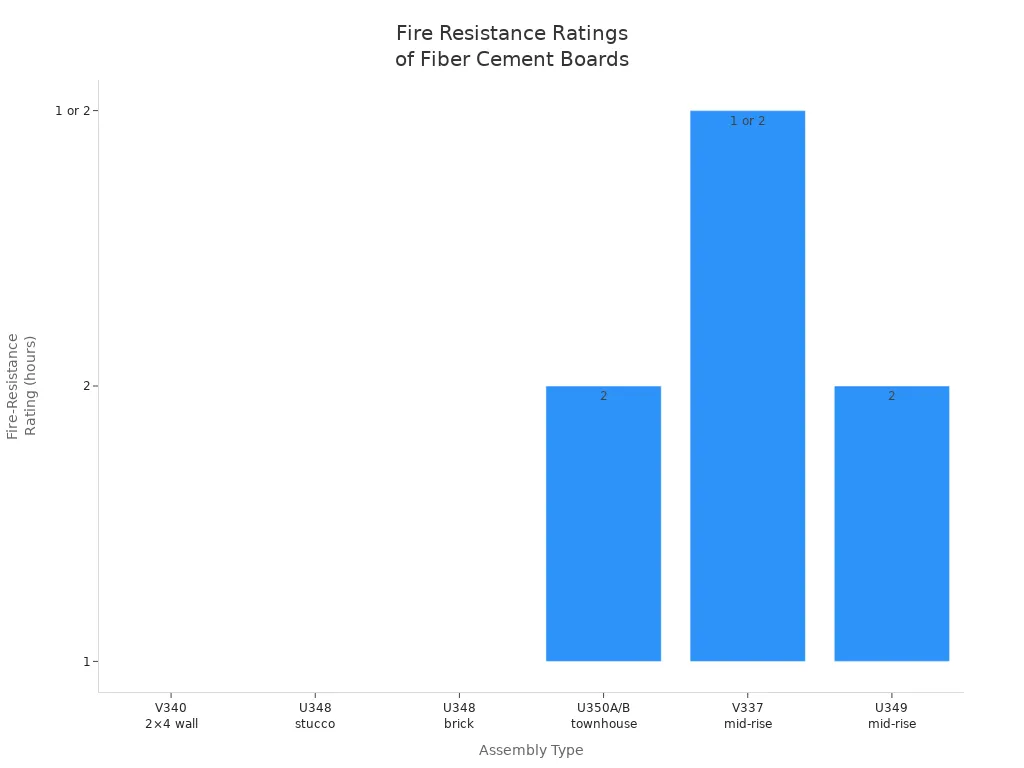

It also protects well against fire. The table below shows how fiber cement siding meets fire safety rules:

UL Design No. | Assembly Type | Fire-Resistance Rating | Notes/Benefits |

|---|---|---|---|

V340 | 2×4 wall construction | 1-hour both sides | No exterior gypsum needed; wall thickness stays the same |

U348 (stucco) | Stucco exterior | 1-hour both sides | Used in many apartments; fiberglass insulation allowed |

U348 (brick) | Brick exterior | 1-hour both sides | Like the stucco assembly |

U350A, U350B | Townhouse dividing walls | 2-hour fire-resistance | Used instead of shaft wall; regular framing; STC rating of 61 |

V337 | Mid-rise exterior walls | 1-hour or 2-hour | 1-hour from either side or 2-hour inside/1-hour outside |

U349 | Mid-rise wall assemblies | 2-hour interior | Keeps wall strong; some water-resistant coatings work with it |

With fiber cement siding, you can feel safe from fire and bad weather.

Low Maintenance

Fiber cement siding saves you time and money because it is easy to care for. You do not need to paint or fix it as much as other siding. The table below shows simple things you should do to keep your siding nice:

Maintenance Task | Frequency |

|---|---|

Visual Inspection | Every few months |

Gutter Maintenance | Twice a year |

Trim Back Landscaping | Once a year |

Caulk | Once a year |

Paint | Every 10 to 12 years |

Clean the Siding | Once a year |

You only need to repaint fiber cement siding every 10 to 20 years. Checking it often helps stop water damage. Vinyl siding might seem easier at first, but it can break, bend, or lose color, so you might need to fix or replace it more. Fiber cement siding is easy to care for and lasts a long time, so your building will look good for years.

Tip: Pick fiber cement siding for your next project if you want something strong, long-lasting, and easy to care for. It works well for many types of siding and cladding jobs.

Types of Fiber Cement Board

Standard vs. Pre-finished

When you choose fiber cement board, you will see two main types: standard and pre-finished. Each type has its own features. You should know the differences before you decide.

Standard fiber cement boards come unfinished. You need to paint or finish them after installation. This gives you more control over the final look. You can match the color to your project.

Pre-finished fiber cement boards arrive with a factory-applied finish. You do not need to paint them. This saves you time and effort during installation. The finish is even and often lasts longer than paint applied on-site.

Pre-finished boards usually cost more than standard boards. The extra cost comes from the added features and the factory finish.

Tip: If you want a quick installation and a uniform look, pre-finished boards work best. If you want to customize the color or save money, standard boards are a good choice.

Panel Sizes and Thickness

You will find fiber cement boards in many sizes and thicknesses. The right size and thickness depend on your project needs. Thinner boards are easier to handle. Thicker boards give more strength.

Thickness Range | Applications |

|---|---|

4mm to 6mm | Ceiling panels, internal partition linings, soffit boards |

8mm to 12mm | Exterior wall cladding, siding, internal dry walls |

16mm to 25mm | Industrial or commercial settings needing high impact resistance |

Common panel widths include 900mm, 1,000mm, and 1,200mm. Lengths range from 2,400mm to 3,050mm. You can pick a size that fits your wall or design.

The thickness of the board affects how strong it is. Thin boards (4mm to 6mm) work well for ceilings or inside walls. They are light and easy to install. Thick boards (10mm and above) are best for outside walls or places that need to resist damage. You get more durability and impact resistance with thicker panels.

Note: Always check your project requirements before choosing the size and thickness. The right choice will make installation easier and improve performance.

Choosing Fiber Cement Board

Certifications and Trademarks

Certifications and Trademarks

When you pick fiber cement board for outside walls, always check for certifications and trademarks. These marks show the board is safe and high quality. You want your board to have national or international certifications. This helps you avoid problems with safety or how long it lasts.

Here is a table that lists important certifications and what they mean:

Certification Type | Description |

|---|---|

CE certificate | Compliance with European standards |

ISO9001 | Quality management systems |

ISO45001 | Occupational health and safety management |

ISO14001 | Environmental management systems |

Fireproof Board | Fire resistance and insulation properties |

Reinforced Board | Enhanced strength and durability |

You should also look for fire safety and insulation certifications. These help you pick the best siding for your project. The next table explains how some certifications affect quality and safety:

Certification | Description | Impact on Quality and Safety |

|---|---|---|

GB8624 | A1-grade non-combustible | Makes sure boards do not catch fire, so they are safer. |

CE12467 | European certification for fire safety | Shows the board meets tough fire safety rules, so it is more trusted. |

CE14306 | European certification for insulation | Proves the board insulates well, which makes it better quality. |

Tip: Always look for trademarks and certifications before you buy. These marks help you avoid bad products and get strong, easy-to-care-for walls.

Climate and Project Needs

Think about your local weather before you choose fiber cement board for outside walls. Different places have different weather problems. The right board will help your building last longer and work better.

Here is a table that shows how climate zones change what you need:

Climate Zone | Challenges | Requirements for Fiber Cement Board |

|---|---|---|

Hot/Dry | UV stability, thermal insulation | Needs insulation to keep buildings cool |

Mixed-Humid/Marine | High humidity, moisture management | Needs drainage to handle moisture |

Cold | Long winters, thermal breaches | Needs to handle freezing and have good insulation |

High Wind/Hurricane | Structural strength under high winds | Needs strong fasteners and extra support |

WUI/Fire-Prone | Risk of wildfires | Needs to resist fire and not burn |

You should also think about your project’s special needs. Here are some things to remember:

Wind and rain can change how well the siding protects your walls.

The way the siding looks can help your building meet wind codes and look nice.

Note: If you live where hurricanes happen, pick fiber cement board that can handle strong winds. In cold places, choose boards that do not break when it freezes.

Comparing Brands

Pick a brand that is known for quality, good help, and strong warranties. Some brands are better because they make customers happy. Here are three top brands for fiber cement board for outside walls:

James Hardie: Very strong and good in storms.

Nichiha: Looks like wood and lasts a long time.

Allura: Has many colors and extra products.

Warranties and help after you buy are important. The table below compares two top brands:

Brand | Warranty Coverage | Key Features |

|---|---|---|

Allura | 50-year warranty on siding | Resists mold and moisture, easy to put up |

James Hardie | 30-year non-prorated substrate warranty | ColorPlus® finish, stands up to weather, fireproof |

Look for brands with long warranties and good help. These things help you get the most from your fiber cement board for outside walls.

Tip: Pick a trusted brand for your outside walls. This helps you avoid problems and keeps your walls strong for a long time.

Installation Guide

Preparation and Tools

Preparation and Tools

You need the right tools and safety gear before you start working with fiber cement board. This helps you work faster and keeps you safe. Use the table below to see what you should have ready:

Tool/Safety Equipment | Description |

|---|---|

HardieBlade® saw blade | Cuts fiber cement with less dust |

Jig saw with fiber cement blade | Makes curved or odd-shaped cuts |

Masonry bits | Drills holes in fiber cement |

Carbide-tipped hole saw | Cuts larger holes |

Siding gauge | Keeps siding straight and spaced |

Pneumatic nail guns | Fastens boards quickly |

Smooth-faced hammer | Helps with hand nailing and small fixes |

Dust mask | Protects you from breathing in dust |

Gloves | Shields your hands from rough edges |

Always wear a dust mask and gloves when cutting fiber cement board. Cut boards outside to keep dust away from your workspace.

Step-by-Step Process

Follow these steps for an easy installation. This installation guide helps you get strong, weather-resistant walls.

Clean the outside wall and fix any damage.

Put flashing around windows and doors to block water.

Check the wall framing to make sure it is sturdy.

Cover the wall with a moisture barrier.

Start at the bottom and install fiber cement siding panels. Use 25×5mm self-tapping screws for the base layer. Space fasteners 200-300mm apart and keep 10-15mm from the edge. Drill pilot holes a bit smaller than the screws.

Seal joints and corners with high-quality caulk.

Add trim pieces for a neat look and extra protection.

Paint or finish the siding if needed.

Tip: Always follow the manufacturer’s instructions for safety and best results.

Common Mistakes

You can avoid problems by knowing the most common mistakes and how to fix them. The table below shows what to watch out for:

Mistake | Solution |

|---|---|

Skipping surface preparation | Make sure the wall is clean, level, and strong. Use a moisture barrier. |

Using wrong fasteners | Use corrosion-resistant screws or nails made for fiber cement board. |

Incorrect fastener placement | Keep the right distance from edges and drive fasteners flush. |

Not sealing cut edges | Prime and seal all cut edges right after cutting. |

Ignoring expansion gaps | Leave space between boards and use flexible sealants. |

Improper joint treatment | Use alkali-resistant tape and joint compound. |

Painting without priming | Always prime before painting. Use acrylic exterior paint. |

Cutting boards incorrectly | Use special blades and cut outside to reduce dust. |

Overlooking moisture management | Install a moisture barrier and make sure water can drain. |

Rushing installation | Read the installation guide and follow all steps. |

Note: Careful planning and attention to detail lead to a long-lasting and attractive finish.

Cost of Fiber Cement Board

Material and Labor Costs

When you plan to build outside walls, you need to know the costs. Fiber cement board is not the cheapest choice, but it is worth the price. In the United States, materials and installation cost between $6.65 and $14.12 for each square foot. Most people pay $10 to $13 per square foot for everything.

Many things change the price:

The kind of fiber cement siding you pick, like pre-finished or unfinished, changes how much you pay.

If your project has lots of corners, windows, or doors, labor costs go up.

Heavy boards are harder to put up, so workers charge more.

Here is a table that shows how fiber cement board compares to other siding:

Feature | Fiber Cement Board | Wood Siding | Vinyl Siding |

|---|---|---|---|

Initial Cost | Higher | Highest | Lowest |

Installation | High labor cost | High labor cost | Low labor cost |

Maintenance | Low | High | Very Low |

Durability | Excellent | Good | Fair |

Lifespan | 50+ years | 20-40 years | 20-30 years |

Long-term Value | Excellent | Variable | Good |

Note: Fiber cement board costs more at first, but you save money later because it lasts longer and needs less work.

Long-Term Value

You want your money to be well spent. Fiber cement board gives you good value for many years. Over 20 years, fiber cement siding pays back about 75.6% of what you spend to install it. This is better than most other home upgrades, like fixing bathrooms or kitchens.

Fiber cement siding can last 50 to 100 years if you take care of it.

When you sell your house, you can get back about 88% of your costs, which is more than vinyl siding.

The 2024 Cost vs. Value Report says fiber cement siding adds about $18,230 to a home’s resale value. Vinyl siding adds $13,957.

Fiber cement board is strong and easy to care for, so you spend less on repairs. It also helps save energy and makes your house worth more. Picking fiber cement board is a smart choice. It protects your house and saves you money for a long time.

Maintenance Tips

Cleaning and Upkeep

Cleaning and Upkeep

You want your fiber cement siding to look its best and last for years. Regular cleaning helps keep dirt, mold, and stains away. You do not need harsh chemicals or special tools. Instead, use gentle methods that protect the surface.

Use a soft cloth, soft paint brush, chip brush, horsehair brush, or siding brush to remove dirt and debris.

For oil or grease spots, mix mild liquid dishwashing soap with water. Wipe the area with a soft cloth, then rinse with a garden hose.

If you see mold or mildew, choose a mildew cleaner that is safe for fiber cement siding. Apply it with a soft cloth or sponge, then rinse well with water.

Tip: Clean your siding once a year or after a big storm. This keeps your home looking fresh and prevents buildup.

Repair and Longevity

You should inspect your siding every year. Focus on areas near the ground, under roof eaves, and next to decks. Look for visible cracks, warping, loose panels, moisture stains, or places where the siding has pulled away from the wall. Small holes from wildlife can also cause problems by letting in water or pests.

If you find damage, follow these steps to fix it:

Gather tools like fiber cement patching compound, sandpaper, and safety gear.

Clean the damaged area to help the repair material stick.

Fill cracks or small holes with patching compound. Smooth the surface and let it dry.

If a panel is badly damaged, remove it and install a new one. Seal any gaps with caulk.

Paint or finish the repaired spot with matching exterior paint.

Regular cleaning and quick repairs help your fiber cement siding last for decades. You protect your investment and keep your home safe from weather and pests.

You can make good choices for your outside wall project by following some easy steps. First, think about your local weather, how to install the boards, and how well they work. The table below can help you pick the right board:

Key Factor | Description |

|---|---|

Climate Considerations | Choose the right thickness and sealing for your weather. |

Installation Details | Pick the best panel size, how to attach them, and waterproofing. |

Performance Metrics | Check for fire rating, water soaking, and bending strength. |

Aesthetic Choices | Pick colors and textures that match your style. |

Always look for certified products and brands people trust. Make a checklist to check weather, strength, and how much care is needed. If your project is tricky, ask experts like FEMA or APA for help with fasteners and how to install. Checking your walls often keeps them strong and looking nice for a long time.

FAQ

How long does fiber cement board last on exterior walls?

You can expect fiber cement board to last 50 years or more. Many brands offer warranties up to 30 or 50 years. Regular cleaning and quick repairs help you get the most life from your siding.

Can you paint fiber cement board?

Yes, you can paint fiber cement board. Use high-quality acrylic exterior paint for best results. Always clean and prime the surface before painting. Pre-finished boards do not need painting right away.

Is fiber cement board safe for fire-prone areas?

Fiber cement board resists fire very well. It does not burn or melt. Many fire safety codes recommend it for homes in wildfire zones. Always check for certifications like UL or CE for extra peace of mind.

What maintenance does fiber cement siding need?

You should inspect your siding once a year. Clean it with mild soap and water. Check for cracks or loose panels. Repaint every 10 to 20 years. Quick repairs help prevent bigger problems.

Can you install fiber cement board yourself?

You can install fiber cement board if you have the right tools and follow safety steps. Use a dust mask and gloves. Always read the manufacturer’s instructions. For large or complex projects, consider hiring a professional.

Durability and Longevity

Durability and Longevity Certifications and Trademarks

Certifications and Trademarks Preparation and Tools

Preparation and Tools Cleaning and Upkeep

Cleaning and Upkeep