05 Oct Fiber Cement Board Alternatives Compared for 2025

Table of Contents

- 1 Key Takeaways

- 2 Fiber Cement Board Alternatives Overview

- 3 Why Pick Other Choices

- 4 MgO Board

- 5 Foam Board

- 6 Glass Mat Gypsum Board

- 7 Wood Siding and Engineered Wood

- 8 OSB and Plywood

- 9 Metal Panels

- 10 Other Notable Alternatives

- 11 Comparing Fiber Cement Board Alternatives

- 12 Choosing the Right Alternative

- 13 FAQ

You have lots of choices for building materials. In 2025, you can choose MgO board, foam board, glass mat gypsum board, wood siding, engineered wood, PVC panels, OSB, plywood, and metal panels. Siding boards are special because they last long, need little care, and resist fire. Fiber cement board alternatives are good for homes. Homes are a big part of the market. If you know the good and bad sides of each choice, you can pick the best material for what you need.

Key Takeaways

Magnesium Oxide (MgO) boards are light and good for the environment. They do not burn easily and do not get wet or damaged by water.

Foam boards keep heat inside and are simple to put in place. They help save money on energy bills.

Glass mat gypsum boards work well in places that get wet. They stop mold and water from causing problems. These boards are good for bathrooms and basements.

Wood siding and engineered wood look natural and nice. You need to take care of them often. This stops bugs and bad weather from hurting them.

Metal panels last a long time and need little care. They protect buildings from strong weather.

Fiber Cement Board Alternatives Overview

Top Alternatives for 2025

There are many choices for fiber cement board alternatives in 2025. Each one has special features to help with your project. Here are the main options you should know:

Magnesium Oxide (MgO) Boards: These boards are light and good for the environment. They do not get damaged by water or fire. Many people use them because they are safe.

Foam Boards: Foam boards keep heat in very well. They are light and save money. They do not last as long as some other boards.

Glass Mat Gypsum Boards: These boards are good in wet places. They do not get weak from water. They stay strong for a long time.

Wood Siding and Engineered Wood: These give a natural look. You can put them up and fix them easily.

PVC Panels: These panels do not get damaged by water. They do not rot. You can use them in places that get wet.

OSB (Oriented Strand Board) and Plywood: These panels are strong and not expensive. You can use them for many building jobs.

Metal Panels: Metal panels last a long time. They do not burn. You can use them for walls and roofs.

Other Notable Options: Some brands have special boards. These include Allura fiber cement backer board, DensShield, Schluter Ditra, LP SmartSide, and mat-faced gypsum cover board.

Tip: Always pick the board that fits your project. Think about water, fire safety, and how long you want it to last.

Quick Comparison Table

Alternative | Key Strengths | Best For |

|---|---|---|

Magnesium Oxide (MgO) | Water/fire resistance, green | Walls, wet areas |

Foam Board | Insulation, lightweight | Interior, insulation |

Glass Mat Gypsum | Moisture resistance | Bathrooms, basements |

Wood/Engineered Wood | Natural look, easy repair | Siding, decorative walls |

PVC Panels | Water resistance, no rot | Kitchens, bathrooms |

OSB/Plywood | Strength, affordability | Subfloors, sheathing |

Metal Panels | Durability, fire resistance | Exteriors, roofs |

Specialty Boards | Unique features | Specific applications |

Why Pick Other Choices

Problems with Fiber Cement Board

Problems with Fiber Cement Board

Some people think fiber cement board is strong. But it has some problems you should know about.

It costs a lot at first, sometimes double or triple other materials.

You must clean and paint it often to keep it nice.

The board is heavy, so moving and putting it in is hard.

It does not look special, so you might want something with more style.

You have to take care of it often to stop damage.

The board can soak up water, which may cause mold or other issues.

Making the board is not good for the earth.

Shipping heavy boards makes more pollution.

It does not keep heat in as well as some other boards.

Note: If you want something that lasts longer and needs less work, you should look at other choices.

When to Look at Other Materials

You might want a different board if you care about the earth or want to save money. Builders try new things to make less pollution and use more recycled stuff. Many people want to use less energy in their homes. You may also want a board that costs less and is easier to put in.

Here are some reasons to pick something else:

You want your project to be better for the earth.

You need a board that is easier to recycle.

You want your building to use less energy.

You want to spend less money.

You should also think about what your project needs. The table below shows when you might pick a different board:

Scenario | Recommended Alternative | Reason for Alternative |

|---|---|---|

Large spaces needing load support | Cement Board | Gives more help for heavy things |

Vertical surfaces (e.g., fireplaces) | Cement Board | Good for walls that go up and down |

Tiling projects needing uncoupling | Ditra | Helps tiles move without breaking |

Tip: Always pick the board that fits your project. This helps you get better results and saves time.

MgO Board

Pros

MgO board is a smart pick for many jobs. It stops fire and mold very well. These boards are lighter than fiber cement boards. You can move and put them in with less work. MgO boards are good for the earth because you can recycle them. They do not make much pollution. They help keep the air inside safe for people.

Here is a quick chart to show how MgO board and fiber cement board are different:

Feature | MgO Board | Fiber Cement Board |

|---|---|---|

Composition | Magnesium oxide | Cement and cellulose fibers |

Fire Performance | Superior fire resistance | Moderate fire resistance |

Moisture and Mold Resistance | Inhospitable to mold growth | Moderate resistance |

Weight | Lighter | Heavier |

Environmental Considerations | Eco-friendly, recyclable | Higher carbon footprint |

MgO boards last a long time. They do not get ruined by bad weather or water. If you need a strong board for busy places, MgO is a good choice.

Tip: Use MgO boards where you need safety and strength.

Cons

MgO boards have some problems too. They cost more at first than drywall or plywood. You might not find them in every store. You may wait longer or pay more for shipping. You must seal MgO boards well to stop water damage. If you do not put them in right, you can get bad cuts or weak glue. The quality can change from brand to brand. Some paints and glues do not stick well to MgO boards.

Costs more at first

Not easy to find everywhere

Needs careful sealing when installed

Quality changes by brand

Some glues and paints do not work well

Note: Ask your supplier how to install and finish MgO boards the best way.

Best Uses

MgO boards work for many projects. You can use them for walls, ceilings, and floors in homes. They stop fire and water. Offices and stores use MgO boards for walls and panels. Factories use them where chemicals and heavy use happen. You can cut and shape MgO boards to fit your design. You can paint them for cool walls or use them outside for safe siding.

Project Type | Application of MgO Boards |

|---|---|

Residential | Walls, ceilings, floors |

Commercial | Partitions, protective panels |

Industrial | Chemical resistance, impact strength |

Renovation | Cut and shape for custom fit |

Interior Design | Feature walls, decorative panels |

Cladding/Siding | Exterior safety, weather resistance |

MgO boards help you build safe, green, and strong spaces. If you want a board for inside and outside, MgO gives you lots of choices.

Foam Board

Pros

Foam board is a good choice if you want something instead of fiber cement board. It keeps your house warm in winter and cool in summer. This helps you pay less for energy. Foam board does not let water in, so mold and rot are not a problem. It is light, so you can carry it without trouble. You can cut it with easy tools. This makes putting it in fast and simple. Foam board stays strong when it gets hot or cold. You do not see cracks or breaks often. It also helps stop noise from going between rooms. If you want to put tiles on top, foam board gives a flat base. You pay less for workers, and you might save money later.

Main benefits of foam board:

Moisture resistance for damp areas

Lightweight for easy handling

Simple installation with basic tools

Dimensional stability to prevent cracks

Soundproofing between spaces

Good base for tile installations

Cost-effective with lower labor and energy costs

Tip: Foam board is a good pick if you want to save energy and finish your project fast.

Cons

There are some things to think about before you pick foam board. Foam board is made from oil, so it does not break down in the ground. It can stay in landfills for a very long time. Foam board can catch fire easily, and fire blockers may not last forever. You must cover it with special boards to keep it safe. Foam board can cost more than other types of insulation. Some people do not want to pay more at first. The board is stiff, so it does not bend to fit odd shapes. Some kinds can get ruined if they touch certain things.

Limitation | Description |

|---|---|

Made from non-renewable petroleum; non-biodegradable, takes hundreds of years to decompose. | |

Fire Risks | Highly flammable; fire retardants may fade, needs coverage with fire-rated materials. |

Cost | Often more expensive than traditional insulation, may deter some homeowners. |

Limited Compatibility | Rigid nature; not suitable for irregular shapes, can degrade with some materials. |

Note: Always check your local rules before using foam board, especially for fire safety.

Best Uses

Foam board works for many building jobs. You can use it as a layer over plywood or OSB. This is best where there is lots of rain or strong weather. You can also put foam board over wood studs. This works in most places with rain but needs careful work. Some builders put housewrap over foam board and wood studs. This is good for most rainy places but may not last as long. In dry places, you can use foam board as the drainage layer, but this is more risky.

Wall Section | Description | Suitability |

|---|---|---|

1 | Most durable; best for high exposure/rainfall | |

2 | Insulation sheathing and housewrap over wood studs | Effective in most rainfall zones |

3 | Housewrap over insulating sheathing and wood studs | Suitable for most rainfall zones |

4 | Insulating sheathing as drainage plane | Higher risk; best for dry, low-exposure areas |

You can use foam board for walls, roofs, and floors where you need strong insulation and to keep out water.

Glass Mat Gypsum Board

Pros

Pros

You can count on glass mat gypsum board for strong performance in tough conditions. This board stands up well to moisture. You will not see it break down in wet areas. It also resists mold, which helps keep your home or building safe. You can use it in places where fire safety matters. The board gives you a plain surface that you can paint or finish as you like. You get a product that lasts a long time and works well in many climates.

Here is a quick comparison between glass mat gypsum board and fiber cement board:

Material | Durability | Moisture Resistance | Installation Difficulty | Aesthetics | Cost |

|---|---|---|---|---|---|

Glass Mat Gypsum Board | Very High | Excellent | Hard | Plain, paintable | High |

Fiber Cement Board | Very High | Excellent | Hard | Plain, paintable | High |

You will find that both boards offer similar strengths. Glass mat gypsum board gives you extra protection from mold and water. You can trust it in places where you need strong, lasting walls.

Tip: Choose glass mat gypsum board if you want a board that handles moisture and fire without trouble.

Cons

You should know about some challenges before you pick glass mat gypsum board. The board feels heavy, so you may need help to move it. When you cut it, you will see dust in the air. You must wear a mask and goggles to stay safe. The edges can chip, and these chips may scratch tubs or shower bases if you are not careful.

Heavy to carry and install

Cutting creates silica dust; use protective gear

Chips from cut edges can scratch surfaces

Note: Always use safety tools and clean up chips right away to protect your work area.

Best Uses

You can use glass mat gypsum board in many types of projects. Builders often pick it for commercial buildings. You will also see it in homes, especially in one- and two-story houses. This board works well in places with wildfires or strong storms. You get mold and moisture resistance, fire protection, and a board that fits many cladding systems. It keeps out wood-boring insects and gives you extra weather protection.

Commercial construction projects

Residential homes, especially one- and two-story dwellings

Areas with wildfire risk or severe weather

Mold and moisture resistance

Fire protection

Works with many cladding systems

Extended weather protection

No risk from wood-boring insects

Tip: Pick glass mat gypsum board for bathrooms, basements, and any place that needs strong, safe walls.

Wood Siding and Engineered Wood

Pros

You might choose wood siding or engineered wood if you want a natural look for your building. These materials give your home warmth and charm that many people love. You can paint or stain wood in many colors. This lets you match your style or change it later. Engineered wood often comes pre-finished, so you can install it quickly.

Wood siding is easy to repair. If a board gets damaged, you can replace just that piece. Engineered wood is lighter than fiber cement board, so you can handle and install it with less effort. Both options are good for DIY projects. You can cut and shape them with basic tools.

Tip: Wood siding works well if you want a classic look and enjoy working on your home.

Cons

You need to know that wood siding and engineered wood require more care than fiber cement board. Wood siding needs regular painting, sealing, and caulking. If you skip these steps, the boards can rot or get damaged by pests. Engineered wood can absorb moisture, which may cause it to swell or crack. You might see color fading or resin coat cracking over time. Some warranties do not cover all types of damage.

Engineered wood may absorb moisture and swell.

Both types need regular maintenance to prevent damage.

Color can fade, and resin coats may crack.

Woodpeckers and insects can harm the boards.

Warranties might not protect against every problem.

Here is a table to help you compare costs and maintenance:

Siding Type | Initial Cost (Per Sq. Ft.) | Maintenance Cost (Over 30 Years) | Total Estimated Cost |

|---|---|---|---|

Fiber Cement | $6–$10 | Low to Moderate | $$ |

Wood | $5–$9 | High | $$$ |

Note: Wood siding can last 20 to 40 years, but only if you keep up with maintenance. Fiber cement siding lasts longer and needs less work.

Best Uses

You can use wood siding and engineered wood on many types of buildings. Lap siding works well for homes and stands up to weather. Drop channel siding fits high-rain areas and can go up in different directions. Tongue and groove siding suits stable woods and needs expert advice for best results. Wooden shingle siding looks great but needs lots of care. Split logs give a rustic look and need careful installation. Board-and-batten siding is common on barns and is easy to replace.

Lap siding for homes

Drop channel siding for rainy places

Tongue and groove for stable woods

Wooden shingles for style

Split logs for rustic cabins

Board-and-batten for barns and sheds

Choose wood siding or engineered wood if you want a natural look and do not mind regular upkeep.

OSB and Plywood

Pros

Pros

OSB and plywood are good for many building jobs. Both can hold up walls, floors, and roofs. Plywood is stronger than OSB. It lasts longer too. Plywood does not swell or warp as much. This helps in wet places. Plywood is a smart pick if you want your project to last.

Plywood is stronger than OSB.

It does not swell or warp easily.

Plywood works well in wet places.

Plywood can hold heavy things. It is easy to put in because it is smooth and even. This helps you finish faster. You can use plywood if you build for work or at home. If you seal plywood, it works in many climates. In wet places, use exterior plywood and add a barrier to keep water out.

Tip: Pick plywood if you need strong boards and want to keep out water.

Cons

There are some problems with OSB and plywood. OSB can get ruined by water faster than plywood. The edges of OSB can swell or change shape when wet. OSB changes size more when it gets hot or cold. OSB does not hold nails as well as plywood. This can make your project weaker. OSB siding can look bad over time. It may show marks or weather damage.

Drawback | Description |

|---|---|

Moisture Damage and Rot | OSB can get damaged by water and rot faster than plywood. |

Edge Swelling and Deformation | OSB edges can swell and change shape when wet. |

Dimensional Instability | OSB changes size more when the weather changes. |

Reduced Nail-Holding Capacity | OSB does not hold nails as well as plywood. |

Aesthetic Issues | OSB siding can show marks and weather damage. |

Note: Always check if you need water protection and strong nails before you pick OSB or plywood.

Best Uses

You can use OSB and plywood for many building jobs. OSB is best for walls, floors, and roofs. Plywood works well for bathrooms, kitchen cabinets, and nice furniture. OSB gives strong support for floors and walls. Plywood is smooth and looks good for cabinets and furniture.

Material | Best Suited Applications |

|---|---|

OSB | Wall sheathing, subflooring, roof decking |

Plywood | Bathroom remodeling, kitchen cabinets, high-end furniture crafting |

If you want strong walls or floors, use OSB. For cabinets or furniture, plywood is better and lasts longer.

Metal Panels

Pros

Metal panels are very strong and protect buildings well. They last a long time, even in bad weather. You do not have to take care of them much. Just clean them sometimes to keep them nice. Metal panels help keep your home safe from fire. This is good if you live where wildfires or storms happen. You can pick from many colors and styles. Some metal panels look like wood, so you get both style and strength.

Here is a table that shows the main good things about metal panels compared to fiber cement board:

Advantage | Description |

|---|---|

Durability | Metal is one of the strongest siding products available, able to withstand severe weather conditions. |

Low Maintenance | Requires minimal upkeep, mainly just occasional cleaning to maintain appearance. |

Provides increased safety against fire, ideal for areas prone to wildfires or lightning storms. | |

Curb Appeal | Available in various styles and colors, can mimic the look of wood, enhancing the home’s appearance. |

Tip: Metal panels are a great choice if you want siding that lasts and looks good.

Cons

There are some things to think about before picking metal panels. If you do not use the right coating, metal can rust. This happens more near the ocean or in wet places. Metal panels can get dents if something hits them hard, like hail or a ball. You might hear more noise from rain or wind unless you add soundproofing. Metal lets heat and cold in fast, so you may need more insulation to stay comfortable. Metal panels cost more at first than other materials, but they last longer and need less care.

Here is a table that lists the most common problems:

Limitation | Description |

|---|---|

Corrosion | Metal panels can rust if not coated well, especially in humid or coastal areas. |

Denting | Panels can dent from impacts, such as hail or debris. |

Thermal Conductivity | Metal transfers heat and cold easily, so extra insulation is often needed. |

Acoustic Performance | Metal can let in more noise unless you add sound-dampening layers. |

Cost | The starting price is higher than many other siding options. |

Note: Always ask about coatings and insulation when you buy metal panels.

Best Uses

Metal panels work for many kinds of buildings. They are good for big places like warehouses, schools, and hospitals. You also see them in airports, stadiums, and cold storage buildings. Metal panels are a smart pick for places that need strong, safe, and easy-to-care-for walls or roofs.

Project Type |

|---|

Industrial and commercial |

Warehouses |

MFC Facilities |

Schools |

Hospitals |

Airports |

Stadiums |

Cold storage facilities |

Metal panels are best when you need strength, safety, and a modern look. If you want something that lasts a long time for a big building, metal panels are a smart pick.

Other Notable Alternatives

Allura Fiber Cement Backer Board

You can use Allura Fiber Cement Backer Board for tile projects and wet areas. This board resists water and mold. You get a strong surface for tile. You can cut it with basic tools. The board does not warp or swell. You need to seal the edges for best results.

Key Features:

Water and mold resistance

Easy to cut and install

Stable surface for tile

Tip: Use Allura in bathrooms, kitchens, and laundry rooms.

DensShield

DensShield gives you a waterproof surface for walls and floors. You can install it quickly. The board has a built-in moisture barrier. You do not need extra waterproofing. You can use it behind tile or in showers. DensShield resists mold and mildew.

Pros:

Built-in moisture barrier

Fast installation

Mold resistance

Cons:

Not for exterior use

Needs careful edge sealing

Note: DensShield works best for indoor wet areas.

Schluter Ditra

Schluter Ditra is a plastic membrane. You use it under tile. It stops cracks and helps tiles last longer. You can roll it out and cut it to size. The membrane keeps water away from the subfloor. You get a flat, stable base for tile.

Feature | Benefit |

|---|---|

Uncoupling | Prevents tile cracks |

Waterproofing | Protects subfloor |

Lightweight | Easy to handle |

Use Schluter Ditra for bathrooms, kitchens, and entryways.

LP SmartSide

LP SmartSide gives you siding that looks like wood. You get a strong board that resists impact. The siding does not rot or get damaged by insects. You can paint it any color. You install it with basic tools. LP SmartSide lasts for many years.

Advantages:

Wood-like appearance

Impact resistance

Paintable surface

Best Uses:

Home exteriors

Sheds and garages

LP SmartSide is a good choice if you want a wood look with less upkeep.

Mat-Faced Gypsum Cover Board

Mat-Faced Gypsum Cover Board protects roofs and walls. You get fire resistance and moisture protection. The board is easy to cut and install. You can use it under roofing or as a cover for walls. It works well in commercial buildings.

Main Benefits:

Fire and moisture resistance

Easy installation

Good for roofing systems

Choose mat-faced gypsum cover board for flat roofs and commercial projects.

Comparing Fiber Cement Board Alternatives

When you choose a building material, you want to know how each option stacks up. You should look at cost, how long it lasts, how hard it is to install, and what jobs it does best. The table below gives you a quick way to compare the top alternatives to fiber cement board.

Material | Durability (Years) | Maintenance | Installation Difficulty | Best Uses | |

|---|---|---|---|---|---|

Fiber Cement Board | $4 – $6 | 15 – 20 | Moderate | Hard (heavy, dusty) | Siding, wet areas |

MgO Board | $6 – $10 | 20+ | Low | Medium | Walls, fire zones |

Foam Board | $5 – $8 | 10 – 15 | Low | Easy | Insulation, interiors |

Glass Mat Gypsum Board | $6 – $10 | 15 – 20 | Low | Hard | Bathrooms, basements |

Wood/Engineered Wood | $5 – $9 | 10 – 20 | High | Easy | Siding, decorative walls |

PVC Panels | $7 – $12 | 20+ | Low | Easy | Wet areas, kitchens |

OSB | $3 – $5 | 5 – 10 | Moderate | Easy | Subfloors, sheathing |

Plywood | $4 – $8 | 5 – 10 | Moderate | Easy | Cabinets, furniture |

Metal Panels | $8 – $15 | 30+ | Low | Medium | Exteriors, roofs |

🛠️ Tip: Fiber cement board and magnesium oxide board both give you strong, long-lasting surfaces. They resist mold and cracking, so you can use them in busy places.

You will notice that fiber cement board is heavier than most other options. You need more effort to install it, and you must wear safety gear because cutting it makes dust. If you want something lighter, foam board or engineered wood might work better for you.

Fiber cement board and MgO board last the longest and need less repair.

Plywood and OSB cost less but do not last as long. You may need to replace them sooner.

Metal panels cost more at first but can last over 30 years with little care.

You should also think about how much work you want to do later. Wood siding looks nice but needs painting and sealing. Fiber cement board lasts longer and costs less than plywood over time, but you must clean and paint it sometimes.

📊 Note: Fiber cement products last 15 to 20 years. Plywood lasts only 5 to 10 years and costs about 40% more than fiber cement board.

Pick the material that fits your budget, project, and how much time you want to spend on upkeep. This way, you get the best results for your home or building.

Choosing the Right Alternative

You want to pick the best building material for your project. Start by thinking about what you need most. Do you care about cost, how long the board lasts, or how easy it is to install? Each fiber cement board alternative has strengths and weaknesses. You can match the right board to your needs by looking at a few key points.

Here are the top criteria to consider:

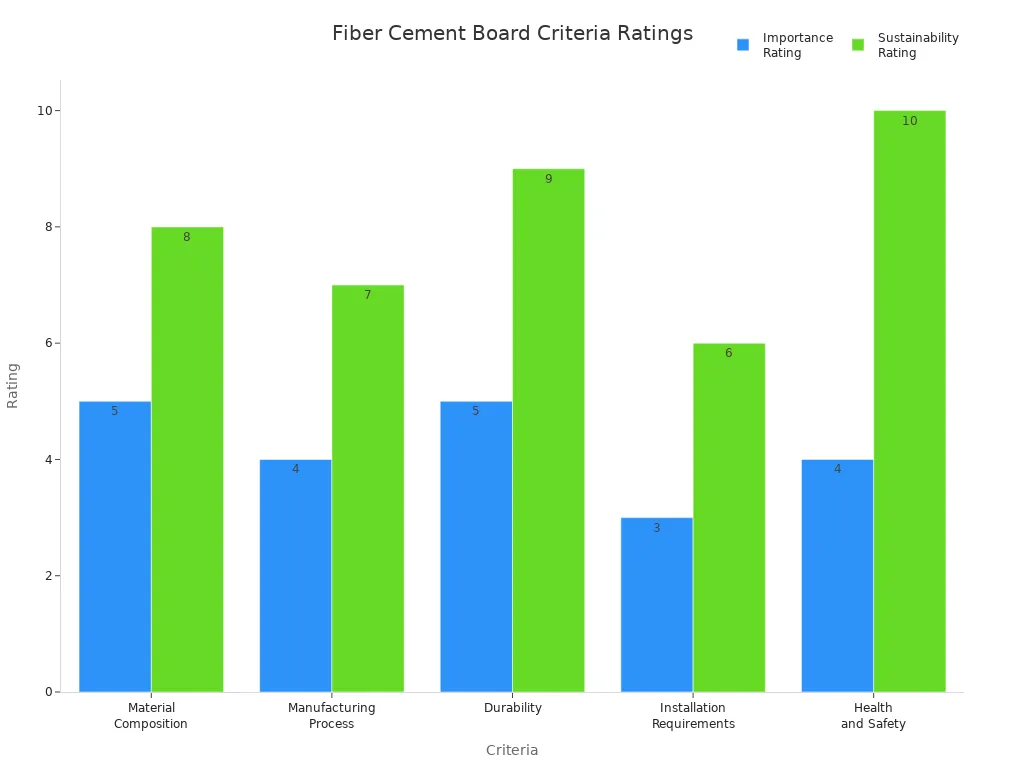

Criteria | Description | Importance (1-5) | Sustainability Rating (1-10) |

|---|---|---|---|

Material Composition | What is the board made of? | 8 | |

Manufacturing Process | How much energy and waste does making it create? | 4 | 7 |

Durability | Will it last through weather, pests, and moisture? | 5 | 9 |

Installation | Is it easy to put in? Does it need special tools? | 3 | 6 |

Health and Safety | Is it safe for you and your family? | 4 | 10 |

You also need to think about climate. If you live in a wet area, pick a board that resists water and mold. For places with wildfires, choose a fire-resistant option. If you want to save money, look for boards that cost less and last longer. Thicker boards give better sound insulation, which helps in busy homes or offices.

The global fiber cement market keeps growing because people want safe and sustainable materials. You can help the planet by picking boards with low carbon footprints and recyclable parts.

Here is a simple way to match your needs:

For wet climates: Use MgO board, glass mat gypsum, or PVC panels.

For fire safety: Pick fiber cement board, MgO board, or metal panels.

For easy installation: Choose foam board, engineered wood, or OSB.

For best insulation: Select foam board or thicker boards.

For low maintenance: Try metal panels or PVC panels.

🏡 Tip: Always check the board’s thickness and density. Thicker boards block more noise and give stronger walls.

You can make a smart choice by listing your project’s needs and matching them to the right board. This helps you build safer, stronger, and more comfortable spaces.

You have many choices for building materials. Each alternative fits a different need:

MgO board works well in wet or fire-prone areas.

Foam board gives strong insulation.

Glass mat gypsum board resists mold.

Wood siding adds natural style.

Metal panels last for decades.

Weigh the pros and cons for your project. Ask a professional or supplier for advice. Make sure you choose the material that matches your goals and budget.

FAQ

What is the best alternative to fiber cement board for wet areas?

You should use MgO board or glass mat gypsum board. Both resist water and mold. These boards work well in bathrooms, basements, and kitchens.

Can you install foam board by yourself?

Yes, you can install foam board with basic tools. The board is light and easy to cut. You save time and money by doing it yourself.

How long does metal panel siding last?

Metal panels can last over 30 years. You do not need much maintenance. Choose panels with good coatings to prevent rust.

Is wood siding a good choice for energy savings?

Wood siding does not insulate as well as foam board. You get a natural look, but you may need extra insulation for better energy savings.

Problems with Fiber Cement Board

Problems with Fiber Cement Board Pros

Pros Pros

Pros