12 Aug Top Tips for Cutting and Handling Cement Board Safely

Table of Contents

Working with cement board means you must be very careful. Cutting cement board lets out tiny bits that can hurt your lungs. You could face big health problems:

Cutting fiber-cement products lets out a dust called respirable crystalline silica. This dust can cause silicosis, which is a deadly lung disease.

Some ways of cutting make even more silica dust. You could breathe in up to 3.4 times more dust than is safe.

Some cement board has asbestos. Asbestos can cause mesothelioma and lung cancer. Asbestos fibers can stay in your body for many years.

Water by itself does not keep you safe from asbestos fibers.

You can stay safe by using the right safety gear and tools. Always handle cement board carefully. This keeps your work area safe and protects your health.

Key Takeaways

Always wear safety gear like gloves, goggles, and a P100 respirator. This will protect your hands, eyes, and lungs from dust and sharp edges.

Use the score and snap method with a utility knife for straight cuts indoors. This helps make less dust and keeps your work area clean and safe.

Control dust by working outside or in places with good airflow. You can use wet cutting or dust collection systems. Clean up with a HEPA vacuum after cutting.

Handle cement board sheets with care by lifting with both hands. Do not drag them. Store them flat to stop damage and help with smooth installation.

Follow the right installation steps. Use the correct tools, fasteners, and weatherproofing. This will help your project stay strong, safe, and last a long time.

Safety Gear for Cement Board

Gloves and Eye Protection

You need to protect your hands and eyes when you cut or handle cement board. Cement board can cause cuts, scrapes, and chemical burns. You should wear sturdy gloves that resist both punctures and chemicals. Coated fabric gloves work well because they have a special layer, such as latex, nitrile, polyurethane, or PVC. These coatings help protect your skin from the alkalinity of cement products. OSHA Standard 1910.138 says you must use gloves that match the hazards you face. Always check that your gloves are in good shape before you start.

Coated fabric gloves resist chemicals and punctures.

Gloves with latex, nitrile, polyurethane, or PVC coatings offer extra protection.

OSHA 1910.138 sets the rules for hand protection.

For your eyes, safety goggles or a face shield are a must. Cutting cement board sends out tiny chips and dust that can hurt your eyes. OSHA’s construction safety guidelines require eye and face protection that meets ANSI/ISEA Z87.1 standards. Make sure your safety goggles fit well and do not fog up.

Tip: Always inspect your safety gear before each use. Replace any damaged items right away.

Respirators and Masks

Cutting cement board creates dust that can harm your lungs. You should wear a dust mask or, even better, a respirator. The best choice is a silicone half-mask respirator with P100 filter cartridges. These filters block at least 99.97% of dust, including silica. N95 and N99 masks also help, but P100 filters give you the highest level of protection. If your work area uses a saw with a dust collection system that meets OSHA standards, you may not need a respirator. Always follow the rules for respiratory protection to keep dust exposure low.

Ventilation Tips

Good airflow helps keep dust levels down. Work outside if you can. If you must work indoors, open windows and use fans to move air out of the room. Set up your cutting area near an exhaust vent or use a portable dust collector. Keep bystanders away from the work area to protect their health.

Note: Always clean up dust and debris after you finish. Use a vacuum with a HEPA filter for best results.

Cutting Cement Board

Marking and Measuring

Marking and Measuring

Accurate marking and measuring help you avoid mistakes when you cut cement board. Follow these steps to get clean, straight cuts:

Use a tape measure to measure the area where you need to cut cement board.

Mark the cutting line with a pencil or a Sharpie marker for better visibility.

Place a straightedge or T-square along your mark to draw a straight, accurate line.

Double-check your measurements before you cut. Remember the saying: “Measure twice, cut once.”

Take your time to make sure your marks are precise. Even small errors can cause problems during installation.

Tip: For thick cement board, score the line with a utility knife to make your mark even clearer.

Score and Snap Method

The score and snap method is the safest and cleanest way to cut cement board by hand. This method creates very little dust and works well for straight cuts. Here’s how you do it:

Measure and mark your cut line using a pencil and a straightedge.

Place the straightedge firmly on the line. Use a utility knife to score along the mark, cutting through the fiberglass mesh on the front side.

Score the line several times to make a deep groove. A sharp blade works best.

Slide the scored board to the edge of your work surface or place a scrap piece of wood under the score line.

Press down on both sides of the board to snap it along the scored line.

Flip the board over and cut any remaining mesh on the back with your utility knife.

Common mistakes to avoid:

Not scoring deeply enough, which makes snapping hard.

Using a dull blade, which can snag the mesh.

Rushing the scoring process, which can cause crooked cuts.

Not supporting the board properly when snapping.

Forgetting to wear a dust mask and goggles.

Note: The score and snap method produces almost no dust, making it the best choice for indoor work.

Power Saw Cutting

Sometimes you need to cut cement board with a power saw, especially for long or curved cuts. Circular saws and jigsaws are the most common tools for this job. Always use a saw with a blade made for fiber cement. These blades have polycrystalline diamond (PCD) teeth and a low tooth count for clean, fast cuts.

Blade Size | Tooth Count | Blade Material | Special Features | Suitable Saw Type |

|---|---|---|---|---|

4 | Steel with PCD | Thin kerf, heat-resistant coating, vibration slots | Circular saws | |

10″ | 6 | Steel with PCD | Durable, designed for fiber cement | Circular saws |

12″ | 8 | Steel with PCD | Clean, efficient cutting | Circular saws |

When you cut cement board with a circular saw, you create a lot of dust. Always wear a P100 respirator and use a dust collection system if possible. Place the board face down before cutting. Mark your line with a pencil and use a T-square to keep the cut straight.

Jigsaws with carbide blades work well for small cutouts or curves. They make less dust than circular saws but are not good for long, straight cuts. Utility knives or the score and snap method make the least dust and are best for most straight cuts.

Warning: Circular saw dust is very abrasive and dangerous to breathe. Always use proper safety gear.

Cut Backer Board for Outlets

You often need to cut backer board for outlets, pipes, or other openings. Here’s how you can do it safely and accurately:

Measure the location of the outlet or pipe on the wall or floor.

Transfer these measurements to the cement board. Mark the outline with a pencil or marker.

For small holes or curves, use a jigsaw with a carbide blade. Drill a starter hole inside the marked area, then insert the jigsaw blade and cut along the outline.

For straight or rectangular openings, score the outline with a utility knife, then tap out the piece with a hammer.

Always wear gloves, goggles, and a dust mask when you cut cement board for outlets.

Tip: Avoid using hole saws for circular cuts. They dull quickly and can make rough edges.

Comparing Cutting Methods

You have several options when you cut cement board. Each method has its pros and cons:

Utility Knife (Score and Snap):

Best for straight cuts.

Produces almost no dust.

Safe and easy for most jobs.

Circular Saw:

Good for long, straight cuts.

Cuts quickly but makes a lot of dust.

Needs a special blade and dust control.

Jigsaw:

Best for small cutouts and curves.

Makes less dust than a circular saw.

Not good for long, straight cuts.

Manufacturers recommend using hand tools like utility knives whenever possible to reduce dust. Only use power tools when you cannot avoid it. Always follow safety rules and use the right blade for the job.

Remember: Cutting cement backer board with the right method keeps your work clean and your lungs safe.

Dust Control When You Cut Cement Board

Cutting cement board creates fine dust that can harm your lungs. You need to focus on dust management to protect yourself and others. Good dust control keeps your work area safe and helps you avoid health problems.

Wet Cutting Methods

Wet cutting is a simple way to keep dust down. You can use a spray bottle or a hose to wet the cement board before and during cutting. Water traps dust particles and stops them from floating in the air. This method works best for small jobs or when you use hand tools. Wet cutting does not remove all dust, but it makes a big difference in managing dust. Always wear gloves and eye protection because wet cement board can be slippery.

Tip: Wet the board just enough to keep dust down. Too much water can make the board weak or messy.

Dust Collection Systems

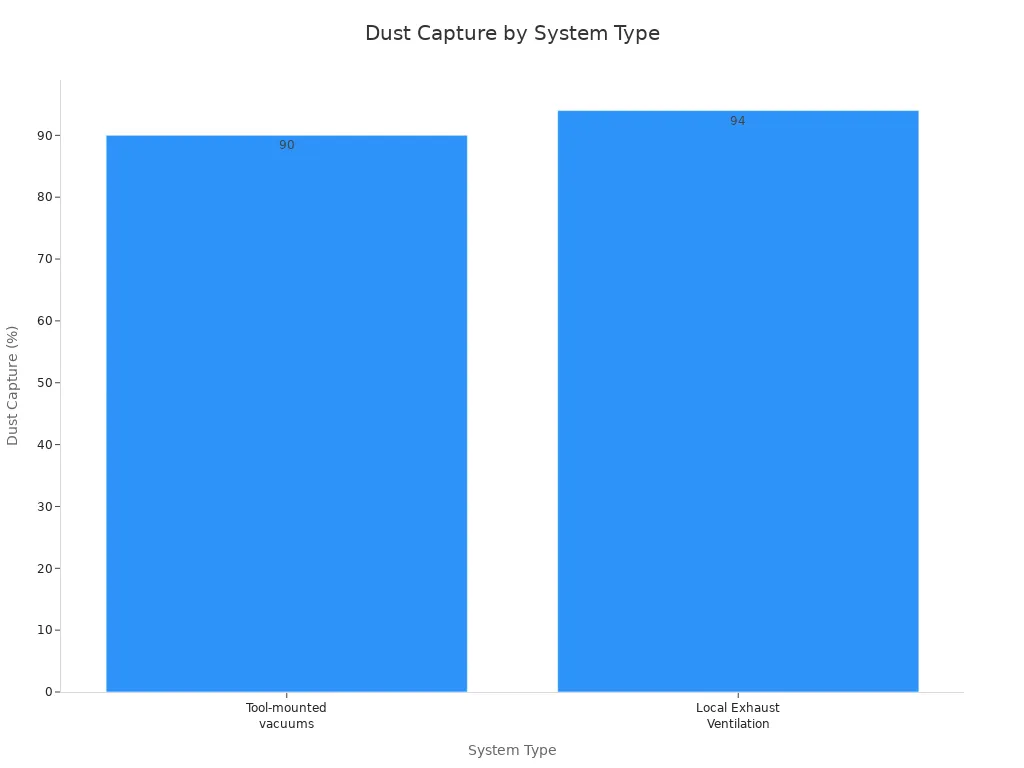

Using a dust collection system is one of the most effective ways to control dust. Tool-mounted vacuums and local exhaust ventilation (LEV) systems can capture up to 94% of airborne dust. For example, a test with Bosch grinders and an Ermator S26 vacuum showed a 94% drop in silica dust, keeping levels below the NIOSH safety limit. Even a shop vacuum attached to your saw can cut dust by 90%. These systems help you avoid a serious health hazard from breathing in fine particles.

Dust Collection System Type | Effectiveness in Dust Capture | Notes |

|---|---|---|

Tool-mounted vacuums | Up to 90% reduction | Simple, low-cost solution for fiber-cement and cement board cutting |

Local Exhaust Ventilation (LEV) | Highly effective, brings exposure below NIOSH limit | |

Wet cutting methods | Not quantified | Effective for dust suppression, but no exact numbers |

Work Area Setup

Setting up your work area the right way helps you avoid dust exposure. Always cut cement board in a well-ventilated space. Open windows or work outside if you can. Wear safety glasses and a dust mask to protect your eyes and lungs. Use ear protection when you run power tools. Choose a circular saw with a fiber cement blade for straight cuts. For less dust, score the board with a utility knife and snap it. Remember, dust from cement board is a health hazard. Prolonged exposure can cause cough, shortness of breath, and even chronic lung disease. You can protect yourself by managing dust and using the right safety steps.

Note: Clean up dust with a HEPA vacuum after you finish cutting. Never sweep dry dust, as this can send it back into the air.

Handling and Installing Cement Board

Lifting and Moving

Cement board sheets can feel heavy and awkward to handle. You need to use the right lifting techniques to protect yourself and the board. Follow these steps to move cement board safely:

Use both hands to lift each sheet gently. This helps prevent the board from snapping.

Avoid dragging boards across rough surfaces. Dragging can chip the edges or corners.

Ask for help when you move large boards. Two people can carry a sheet more safely than one.

Wear gloves and goggles. Gloves protect your hands from sharp edges, and goggles keep dust out of your eyes.

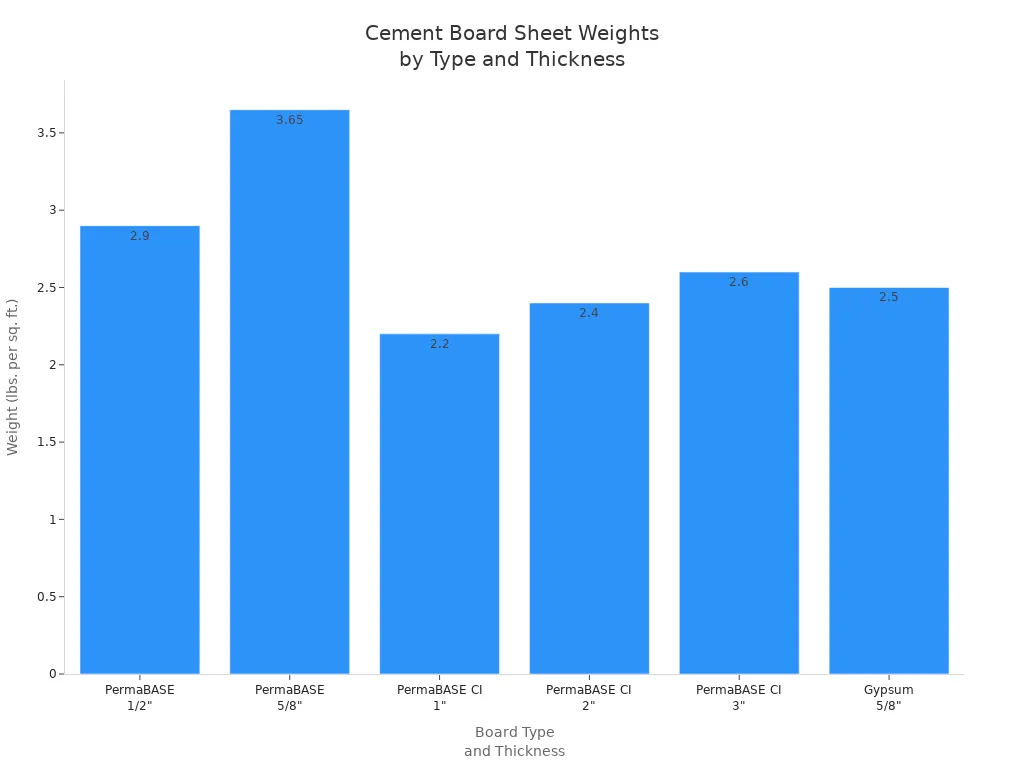

You should also know the weight of different cement board types. The table below shows how much each type weighs per square foot:

Cement Board Type | Thickness | Weight (lbs. per sq. ft.) | Notes on Handling Impact |

|---|---|---|---|

PermaBASE Cement Board | 1/2″ | 2.9 | Slightly heavier than gypsum sheathing; standard handling |

PermaBASE Cement Board | 5/8″ | 3.65 | Heavier, but no special installation problems reported |

PermaBASE CI | 1″ | 2.2 | Lighter insulated board |

PermaBASE CI | 2″ | 2.4 | Lighter insulated board |

PermaBASE CI | 3″ | 2.6 | Lighter insulated board |

Gypsum Sheathing | 5/8″ | 2.5 | Typical sheathing weight for comparison |

Standard 4’x8′ cement board sheets weigh between 2.2 and 3.65 pounds per square foot. You should plan for this extra weight when you lift and move the boards.

Preventing Damage

You want your cement board to stay strong and undamaged. Handle each sheet with care. Never drop the boards or lean them at sharp angles. Store them flat on a level surface. If you need to cut fibre cement decking, always support the board fully to avoid cracks. Keep the work area clear so you do not trip or bump into the boards. When you cut fibre cement decking, use a sharp blade and steady hands to prevent chipping.

Tip: Always check the edges and corners for chips before installation. Damaged boards can cause problems later.

Safe Installation

Proper installation keeps your project safe and long-lasting. Here are some key installation tips:

Remove old siding and inspect the wall for water damage. Repair any weak spots.

Install a water-resistive barrier with the right overlaps to block moisture.

Add flashing around windows, doors, and other openings. This keeps water out.

Use a story pole or marked board to keep your lines straight and level.

Snap chalk lines to mark where studs are and where to start your first row.

Use the right tools to cut cement board, such as shears or a circular saw with a diamond-grit blade and a HEPA vacuum.

Fasten the boards with stainless steel or galvanized nails. This prevents rust and keeps the boards secure.

Wear all safety gear, including a respirator, goggles, gloves, and hearing protection.

Install starter strips to set the angle for the first row.

Use weather-resistant flashing and flexible sealant at joints.

Finish with trim boards for a neat, weatherproof look.

Buy extra material (10-20% more) to cover waste and mistakes.

If you follow these steps, you will have a safe and sturdy installation. Consider professional help if you feel unsure about any part of the process.

You protect your health and improve your work when you use the right safety gear, dust control, and tools for cement board projects. Studies show that training and using dust control systems lower dust exposure and help you follow safety rules. Many accidents happen when workers skip safety steps, forget PPE, or do not keep equipment in good shape. When you follow these tips, you get cleaner cuts, safer jobs, and better results. Always make safety your first step on every project.

FAQ

What is the safest way to cut cement board indoors?

You should use the score and snap method with a utility knife. This method makes almost no dust. Always wear gloves, goggles, and a respirator. Work near an open window or use a fan for better airflow.

Can you cut cement board with regular wood blades?

No, you should not use regular wood blades. Use a blade made for fiber cement. These blades have special teeth that last longer and make cleaner cuts. Using the wrong blade can create more dust and damage your tools.

How do you clean up cement board dust safely?

Use a vacuum with a HEPA filter. Do not sweep dry dust because it can go back into the air. Wipe surfaces with a damp cloth. Always wear a mask and gloves during cleanup.

Do you need to seal cement board edges after cutting?

You do not need to seal most cement board edges. Some brands suggest sealing for wet areas. Check the manufacturer’s instructions for your product. Sealing can help prevent water damage in bathrooms or kitchens.

What should you do if you suspect asbestos in old cement board?

Stop work right away. Do not cut or break the board. Contact a certified asbestos professional for testing and removal. Asbestos fibers are very dangerous if you breathe them in.

Marking and Measuring

Marking and Measuring