10 Oct Cement Board in Modern Construction Pros and Cons Explained

Table of Contents

When considering cement board for your project, it’s important to understand the cement board advantages and disadvantages. Cement board offers strong, durable panels that resist water and mold, making it a reliable choice for areas exposed to moisture. One of the main cement board advantages is its ability to prevent cracks and provide a smooth, even surface. The table below highlights the cement board advantages and disadvantages compared to other materials:

Property / Test | Cement Board | Drywall | Plywood |

|---|---|---|---|

Nearly 100% | Loses 36-52% | Loses 9% | |

Moisture Absorption | Very low | High | Higher than cement board |

Mold Growth | No mold | Mold prone | Mold prone |

However, there are also cement board disadvantages to consider. Cement board tends to be more expensive, requires special tools for installation, and is heavier to handle than other options. Weighing the cement board advantages and disadvantages is essential when evaluating its durability, water resistance, fire safety, installation process, cost, and environmental impact compared to other building materials.

Key Takeaways

Cement board does not get damaged by water easily. It works well in places like bathrooms and kitchens.

This material is safer in fires than drywall. It helps keep buildings and people safe.

Cement board lasts a long time and is very strong. But it weighs more and costs more than drywall or plywood.

Experts should install cement board because it is heavy. It is also hard to handle by yourself.

Cement board saves money on repairs over many years. It does not need much fixing or care as time goes on.

What Is Cement Board

Definition

Cement board is a sheet made from cement and fibers. Makers mix cement with strong fibers to make panels. These panels come in different thicknesses. People use cement board as a base in many building jobs. Builders like cement board because it does not get damaged by water. It gives a solid surface for tile, stone, or other finishes. Building rules say cement board is safe for homes and businesses. Cement board is part of the fibre cement family. Fibre cement boards have cement and fibers to make them stronger. If you pick cement board, you get something that fights water, mold, and fire.

Common Uses

Cement board can be used in many places in a building. Fibre cement boards work for both inside and outside jobs. The table below lists some main ways cement board is used in construction:

Application Type | Description |

|---|---|

Roofing | Waterproof cement boards make roofs strong and safe from fire, even in bad weather. |

Exterior Cladding | Good for keeping out rain and making buildings look nice, which helps the cement board industry grow. |

Interior Walls and Ceilings | Stops fire and water, so it works well in kitchens and bathrooms. |

Flooring | Used under floors to give a steady base for many materials. |

Fibre cement is often used outside because it looks like wood, stone, or brick but lasts longer. Cement board keeps roofs safe from fire and rough weather. Inside, you can put cement board behind tiles in bathrooms and kitchens. This stops water damage and mold. Fibre cement is a strong base for floors in busy places. You can also use cement board as a backer in wet areas to keep walls dry. Builders pick cement board because it is strong, keeps out water, and does not burn easily. You get a tough material that works with many finishes and stands up to hard use.

Cement Board Advantages and Disadvantages

Pros of Cement Board

Pros of Cement Board

Cement board has many good points for building. It gives a tough surface that does not get ruined by water, mold, or fire. You can use cement board in wet places like kitchens and bathrooms. Fibre cement panels work well outside because they do not rot or bend. These panels need little care and protect against bad weather.

Here is a table that shows how fibre cement wall panels compare to regular wall materials:

Feature | PVC Cladding Fiber Cement Wall Panels | Traditional Wall Materials |

|---|---|---|

Weight and Structural Support | Lightweight, reduces structural load | Heavier, requires robust support |

Moisture Resistance | Highly resistant to moisture | Susceptible to rot and mold |

Maintenance | Low maintenance needs | Varies, may require repainting |

Cement board stays strong after getting wet and drying out. Drywall and plywood lose strength, but cement board does not. Fibre cement does not let mold grow, so it is safe in damp rooms.

Cement board also helps protect you from fire. If you want to see how cement board compares to other materials, check this table:

Material Type | Thickness | Fire Resistance Rating |

|---|---|---|

Cement Board (Durock) | 1/2 or 5/8 inch | Up to 2 hours (with proper installation) |

Standard Drywall | 1/2 inch | About 30 minutes |

Type X Drywall | 1/2 or 5/8 inch | 45 minutes to 1 hour |

MGO Board | N/A | Better than cement board |

Cement board gives more fire safety than regular drywall. This makes it a good choice for keeping people safe.

Fibre cement is lighter than stucco, which can weigh up to 12 pounds for each square foot. Most cement board panels weigh less than 3 pounds for each square foot. You can carry and put them in place more easily. This saves time and work when building.

Tip: Cement board is a smart choice if you want a strong and water-resistant base for tile or stone. You do not have to worry about mold or fire hurting it.

Cement board is a safe, tough, and easy-to-care-for option. It gives strong protection and lasts a long time.

Disadvantages of Cement Board

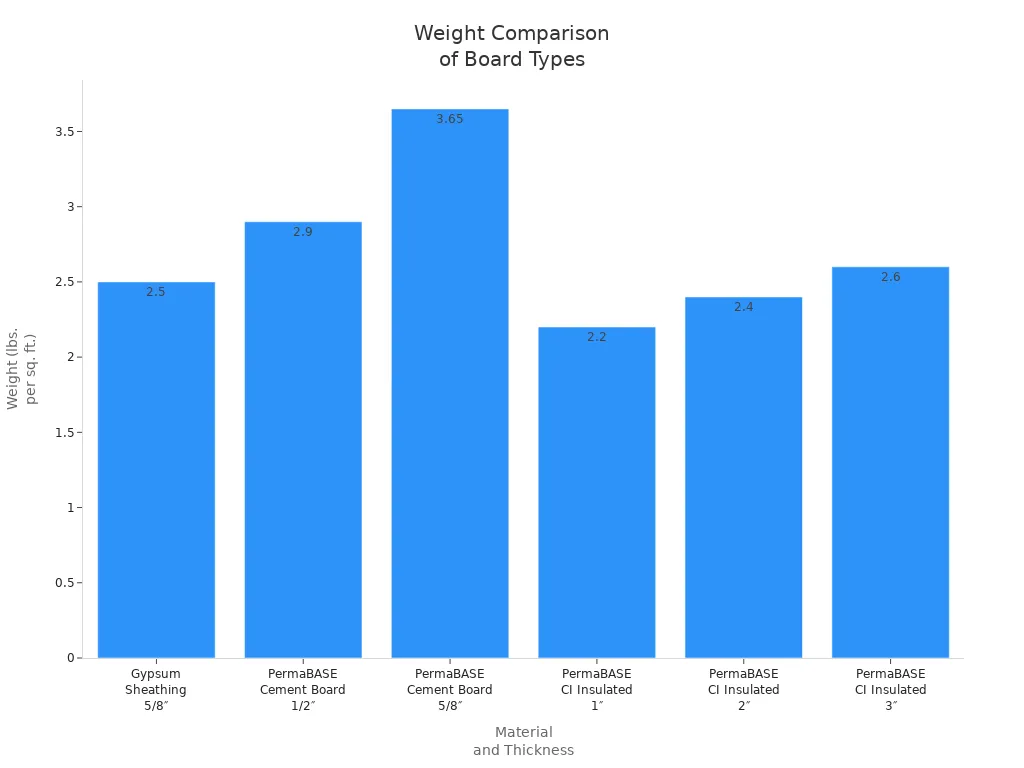

You should think about the bad sides of cement board before picking it. Cement board is heavier than gypsum sheathing. You might need help to lift and put it in place. Here is a chart that shows how much different materials weigh:

Cement board panels can weigh up to 3.65 pounds for each square foot. This means you need more workers and sometimes special tools. Professionals often install cement board because it is heavy and hard to cut.

Putting in cement board can be tricky. You must measure and cut each panel just right. You need nail guns or hammers to attach the panels. You also have to use caulk and flashing to keep water out. Adding a weather barrier helps save energy, but it takes more time.

Cement board is heavy and can be hard to install.

You often need extra support, which means more work.

Professional installers are best for handling heavy materials.

Cement board costs more than drywall. You pay more for the panels and for workers. The total price is close to other strong materials like magnesium oxide board. Here are the main things that affect cost:

Cement board costs more to buy and put in than drywall.

Labor costs are higher because it is heavy and needs skilled workers.

The total price is close to other tough materials like magnesium oxide board.

Cement board does not keep heat in or out very well. Its low R-value means you may need extra insulation in walls. Cement board is stiff, so you cannot bend it for curved shapes. This is one of the limits of fibre cement.

When you look at the good and bad sides of cement board, you see that the choice depends on what you need. Cement board is tough and safe, but it is heavy, costs more, and is harder to put in. You must decide if the strong benefits are worth the downsides for your project.

Durability and Resistance

Strength

It is important for building materials to last a long time. Cement board is very tough and lasts many years. You can use cement board in places that get lots of use. It does not get damaged easily by bumps or scrapes. Drywall gets dents and holes, but cement board stays strong. The table below shows how cement board is better than drywall when it comes to impact resistance:

Aspect | Drywall | Cement Board |

|---|---|---|

Impact Resistance | Gets dents and scratches easily | Stays strong and resists damage |

Cement board does not break in busy places. You can count on it to keep walls and floors safe for a long time. Fibre cement helps you save money because you do not need many repairs. Cement board lasts for many years in different jobs. Here is a table that shows how long cement board lasts:

Application | Expected Lifespan |

|---|---|

Exterior Cladding | 30–50 years |

Interior Walls | 40–60 years |

Ceilings | 35–55 years |

Flooring Substrates | 25–40 years |

Roof Underlayment | 20–35 years |

Tip: Use cement board in places where lots of people walk. It will keep surfaces strong and looking good for many years.

Moisture Resistance

Cement board works well in wet places like bathrooms and kitchens. It does not swell or rot when it gets wet. Particleboard soaks up water and changes shape, but cement board does not. Tests show particleboard can swell a lot after being wet for a long time. Its weight can go up by more than 25%. Cement board does not have these problems.

Cement board does not soak up much water.

You do not have to worry about mold or mildew.

Fibre cement panels are good for inside and outside jobs.

You can feel safe knowing your walls and floors will not get ruined by water. Cement board helps keep the air in your home healthy by stopping mold from growing.

Fire Resistance

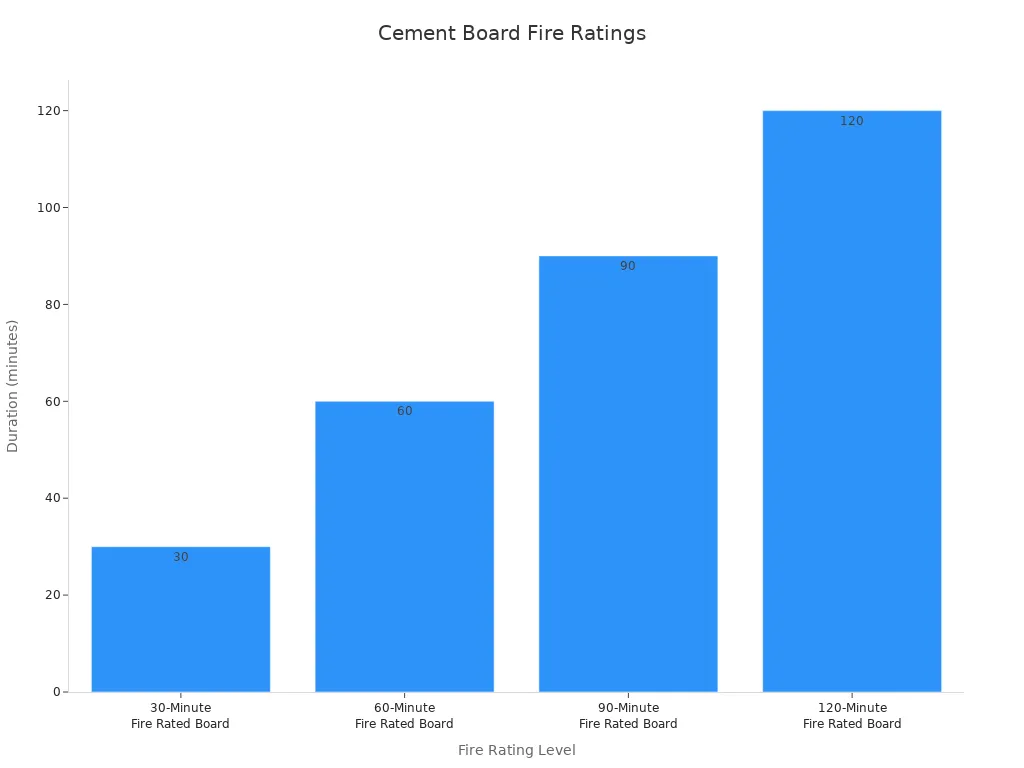

Fire safety is very important in buildings. Cement board gives strong protection against fire. You can use it in places where fire safety matters most. The table below shows how long cement board can resist fire:

Fire Rating Level | Duration of Resistance | Common Applications |

|---|---|---|

30-Minute Fire Rated Board | 30 minutes | Used in small buildings and inside walls |

60-Minute Fire Rated Board | 1 hour | Used in homes and businesses |

90-Minute Fire Rated Board | 90 minutes | Used in places that need more fire safety |

120-Minute Fire Rated Board | 2 hours | Used in hospitals and factories |

Cement board meets tough rules for fire safety. Most good cement boards get a Class A rating for stopping flames and smoke. Fibre cement panels also meet fire safety rules in Europe and the UK. You can use cement board in places where you need extra safety for people and things.

Note: Cement board helps you follow building rules for fire safety. It keeps your building safe and protects everyone inside.

Installation and Cost

Installation Challenges

Working with cement board can be tricky. You have to cut and handle it with care because it is very hard. Cutting panels before you start helps save time. Keep cement board dry before and during installation. Wet boards can bend or get bigger, which can mess up your project. Planning each step and asking experts for help can stop expensive mistakes.

Leave small spaces between cement board panels. These spaces let the boards move when it gets hot or cold. If you forget this, the boards might crack or bend. Use good fillers to fill the spaces between panels. Put the fillers in carefully so cracks do not form. Make sure the finish and color look the same everywhere. This helps your project last longer and look nice.

Here is a table that lists common problems when installing cement board:

Challenge Type | Description |

|---|---|

Handling and Cutting Difficulty | Cutting fibre cement boards can be challenging due to their density; pre-cutting is recommended. |

Moisture and Weather Management | Boards should be kept dry and installed in dry conditions to prevent warping or swelling. |

Complex Installation Requirements | Detailed planning and consultation with professionals can help avoid costly mistakes. |

Expansion and Contraction Issues | Proper gaps must be left between boards to accommodate thermal movement. |

Filling and Jointing Challenges | High-quality fillers should be used, and application must be precise to avoid cracking. |

Aesthetic Considerations | Consistent finishing and color matching are important for the overall appearance and durability. |

Cement board works well for many jobs. You need to follow the right steps to get good results. Cement board goes well with tile and other finishes. This makes it a top pick for wet places. Installing fibre cement takes time and skill, but you get a strong and useful surface.

Cost Factors

Cement board costs more than some other materials. You pay for both the boards and the work to put them in. The price changes based on how big your project is and what kind of cement board you pick. Fibre cement panels usually cost $5 to $14 for each square foot. If you have a 1,500 square foot job, you might spend $7,500 to $21,000.

Think about the cost for both materials and labor. Materials cost $2 to $6 for each square foot. Labor adds $4 to $9 for each square foot. The total cost is usually $6 to $15 for each square foot.

Factor | Average Cost per Square Foot |

|---|---|

Materials | $2 – $6 |

Labor | $4 – $9 |

Total | $6 – $15 |

If you pick James Hardie siding, you pay about $10 to $13 for each square foot. Most fibre cement siding jobs cost $5 to $12 for each square foot to install. Cement board can be used in many ways, but you need to plan for higher costs. It works well with tile and other finishes, which is great for kitchens and bathrooms. You get a strong material that lasts, but you have to pay more at the start.

Tip: Always check prices and benefits before you begin. Cement board is strong and lasts a long time, but you need to spend more money first.

Cement Board vs Alternatives

Drywall

Drywall

Drywall is used a lot in homes and offices. It is light and easy to cut. You can put drywall up fast with simple tools. Cement board is heavier and needs special tools to cut. You have to be careful with cement board because it can break if you drop it. Cement board is stronger than drywall. It does not get damaged easily in busy places. Drywall gets dents and holes more often.

Water can ruin drywall. If you use drywall in bathrooms, it might get mold or fall apart. Cement board works better in wet places. You can put cement board behind tiles in showers and kitchens. Fire safety is important in every building. Cement board protects better from fire than drywall. Cement board helps keep your home safe for longer.

Property | Cement Board | Drywall |

|---|---|---|

Durability | Superior durability, withstands impact | More susceptible to damage |

Moisture Resistance | Ideal for high-humidity areas | Deteriorates quickly when wet |

Fire Safety | Better fire-resistant properties | Offers some fire resistance |

Tip: Pick cement board for bathrooms and kitchens. It gives better protection from water and fire.

Plywood

Plywood is strong and holds up heavy floors. You can use plywood under carpets and wood floors. Cement board is good for tile and stone. If you want a base for tile, cement board is best. Plywood can bend or swell if it gets wet. You need to seal plywood often to keep water out. Cement board does not swell or rot. You can use cement board in wet places without worry.

Material | Structural Strength | Moisture Resistance |

|---|---|---|

Cement Board | Strong and durable; supports tile well. | Highly moisture resistant; does not swell or rot. Ideal for wet areas. |

Plywood | Excellent load-bearing capacity; strong under heavy flooring. | Can absorb moisture; susceptible to warping and swelling if not maintained. |

Note: Cement board needs less care in wet places than plywood.

MgO Board

MgO board is a newer choice. You can use MgO board inside and outside. MgO board protects better from fire than cement board. It does not burn and keeps buildings safe. MgO board uses natural materials. Picking MgO board helps the environment. Cement board uses more energy to make. MgO board costs more at first, but you save money later. You do not need to seal MgO board as much.

Feature | MgO Board | Cement Board |

|---|---|---|

Fire Resistance | A1 non-combustible, superior | Moderate, may require additional |

| fire resistance | fireproofing |

Environmental Impact | Made from natural materials, | Higher environmental footprint due |

| lower energy consumption, no harmful | to energy-intensive production of |

| chemicals | Portland cement |

Upfront Cost | High | Low |

Maintenance Costs | Low | High |

Long-Term Savings | Excellent | Moderate |

Fiber Board

Fiber board is light and easy to put up. You can use fiber board for walls and ceilings. Fiber board does not fight water as well as cement board. If you use fiber board in wet places, it might swell or get mold. Cement board keeps its shape when wet. Fiber cement siding is a top pick for outside walls. You get panels that are very strong and resist water. Fiber cement siding does not burn. You can use fiber cement siding for fire safety. Fiber cement siding helps protect homes from fire. Fiber cement siding does not melt or help fire spread. Fiber cement siding is made with cement, sand, and cellulose fibers. This mix makes fiber cement siding tough and safe. Fiber cement siding lasts for many years. You can use fiber cement siding for long-lasting walls on homes and buildings.

Material | Durability | Moisture Resistance |

|---|---|---|

Fiber Cement Siding | Extremely durable | Highly resistant to water |

Cement Board | Durable | Maintains strength in wet conditions |

Fiber Board | Durable | Less effective in moisture resistance compared to fiber cement siding |

Fiber cement siding does not burn and fights fire.

Fiber cement siding protects homes better than wood or vinyl.

Fiber cement siding gives more safety from fire.

Tip: Pick fiber cement siding for the best mix of strength, water resistance, and fire safety.

You have learned about cement board advantages and disadvantages. Cement board gives you strength, moisture resistance, and fire safety. You pay more at first, but cement board lasts longer and needs less care. Professional installation helps cement board work best. When you choose cement board, think about these points:

Cement board costs $6 to $11 per square foot.

Cement board needs skilled workers for installation.

Cement board saves money over time with low maintenance.

Experts suggest you:

Compare cement board benefits and drawbacks for your project.

Check if cement board fits your needs.

Use waterproof layers with cement board in wet areas.

Cement board works well for many jobs. You should look at your budget, skills, and project needs before you decide.

FAQ

What is cement board made of?

Cement board contains cement and reinforcing fibers. You get a strong panel that does not break easily. Manufacturers mix these materials to make sheets that resist water, mold, and fire. You can use cement board for many building jobs.

Where should you use cement board in your home?

You should use cement board in places that get wet, like bathrooms and kitchens. You can put cement board behind tiles or under floors. Builders also use cement board for exterior walls and roofs because it lasts a long time.

Tip: Cement board works best in areas with high moisture or where you need extra strength.

How does cement board compare to drywall?

Cement board is stronger than drywall. You can use cement board in wet areas, but drywall gets damaged by water. Cement board resists mold and fire better. You need special tools to cut cement board, while drywall is easier to handle.

Feature | Cement Board | Drywall |

|---|---|---|

Water Resistance | Yes | No |

Mold Resistance | Yes | No |

Fire Safety | High | Medium |

Can you install cement board by yourself?

You can install cement board if you have the right tools and plan carefully. Cement board is heavy, so you may need help. You must measure, cut, and attach cement board with care. Many people ask professionals to install cement board.

Does cement board need extra insulation?

Cement board does not keep heat in or out very well. You should add insulation if you want your walls to stay warm or cool. Cement board gives you strength and moisture resistance, but you need insulation for comfort.

Pros of Cement Board

Pros of Cement Board Drywall

Drywall