20 Sep Can Magnesium Oxide Boards Be Recycled?

Table of Contents

Remember the old swing set in the backyard? Though a slight voice might have said, “Isn’t there a way to reuse this stuff?” It’s good to clean the stuff.

That same query, however, also pertains to the building industry!

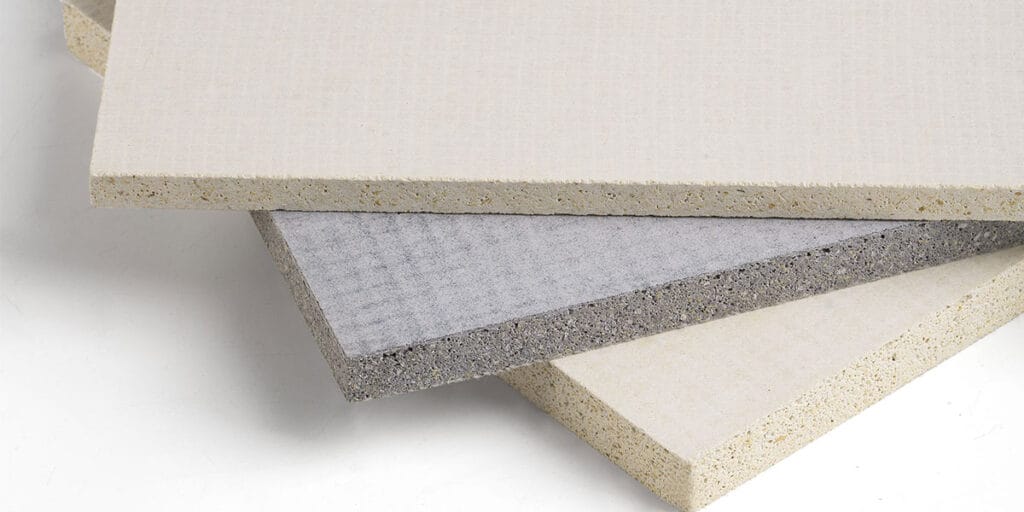

Drywall and other traditional building materials have a concise life span. Therefore, they cannot be reused. But what about magnesium oxide (MgO) boards – the newest kid on the block? MgO boards are a favorite among builders because of their durability and fire resistance.

This blog post will guide you through whether or not MgO boards can be recycled. So hurry up, and let’s jump into the topic.

Magnesium Oxide Boards: A More Eco-Friendly Option

The construction industry rapidly uses magnesium oxide boards, a novel construction material. These panels replace conventional building materials with a more environmentally friendly alternative. Natural substances containing magnesium make up these.

A few of the magnesium oxide boards’ environmental benefits are listed below:

1. Recyclable

MgO boards are made of recyclable materials. This means we can use them again and again for a longer period of time.

2. Low Carbon Footprint

MgO boards use way less energy during processing.This means they have a more minor impact on the environment.

3. Reliable and Sustainable

Magnesium is found naturally on the Earth. Using it for construction doesn’t harm the planet, as the source will not run out anytime soon. That’s why it’s a long-lasting option.

4. Not harmful

As MgO boards are more environmentally friendly, they are free of harmful chemicals and VOCs.

Why Recycling Building Material?

As much construction waste is dumped in landfills, resources are becoming scarce. Traditional construction materials end up in landfills. There, they excrete harmful gasses and thus threaten the environment. Recycling magnesium oxide boards presents a vital substitute:

1. Decreased Landfill trash

We can drastically reduce the quantity of building trash that builds up by recycling. It will make landfill management a hassle-free task.

2. Conservation of Resources

Natural resources are used to produce MgO boards. Recycling these boards helps conserve resources by reducing the use of raw materials.

3. Reduced Energy Consumption

Compared to newly manufactured MgO boards, recycled ones take less energy. This will lead to a more sustainable and low carbon footprint for the construction industry.

Recycling Process

The excellent news about MgO boards is that they can be inherently recycled. The recycling process of MgO boards has a tiresome separation process. The given process can recycle mgO boards:

1. Collection

MgO boards need to be gathered from building or demolition sites. After that, they are segregated to keep them from other debris in the building.

2. Cleaning

Impurities should not be added. The next step is to remove any impurities. These include paint and cladding etc.

3. Crushing and Grinding

The boards are ground into smaller pieces after cleaning. This step is essential to transform the material into a form that can be processed readily.

4. Separation

After that, the ground material is separated to eliminate any contaminants. This could entail applying magnetic separation methods or sieving.

5. Reworking

The refined MgO particles are recycled to create new MgO boards or other goods. This involves combining recycled material with fresh material to guarantee quality and performance.

Benefits of Recycling MgO Boards

Recycling MgO boards comes with several benefits:

1. Decreased Waste

A substantial amount of building waste is avoided by keeping MgO boards out of the landfill. It helps to create a built environment that is more sustainable.

2. Resource Conservation

Recycling MgO boards reduces the necessity of extracting fresh raw materials. They preserve the natural resources used in their production, like magnesium.

3. Decreased Environmental Impact

Manufacturing new MgO boards emits significant carbon dioxide. At the same time, the recycling process of MgO boards has no emission at all.

4. Savings

The recycled materials are less expensive than the original ones. Using recycled MgO boards is cheaper for construction projects.

Applications of recycled MgO boards

As we’ve discussed the advantages of recycling MgO boards, let’s move to the uses of them. The beauty of recycled MgO boards lies in their unique use. Here are some of the potential uses of recycled MgO boards:

1. Panels for Walls and Ceilings

For ceiling purposes and indoor walls, recycled MgO boards are an eco-friendly option. Such recycled MgO boards have increased strength and durability.

2. Flooring Materials

Using recycled MgO boards is a solid option for a base layer in different floor projects. They are durable and can repel water.

3. Fire resistant Cladding

MgO boards are naturally resistant to fire. Even post-recycling, MgO boards remain a valuable resource for creating fire-resistant buildings. Due to their higher strength and impurities, they are most suited for fireproof cladding.

Challenges in Recycling MgO Boards

While recycling MgO boards is beneficial, it also presents many challenges. Here are some of them:

Complexity

Recycling MgO boards is more complicated than other materials. It requires specific tools and procedures. It requires a lot of procedures and activities, thus, a process of taking care of it.

Contamination

Successful recycling depends on the boards being free of pollutants. It might be challenging in specific circumstances. Most of the contamination occurs when the MgO boards are being unplanted. The dust and debris can also pose challenges during recycling.

Market Demand

The market for recovered MgO products may impact the viability of recycling initiatives. Most customers, despite recycled MgO boards, prefer newer ones.

Sulfycor: Crafting the Future with MgO Boards

Do you need help installing MgO boards?

Sulfycor is a well-known manufacturer of magnesium oxide boards that are devoid of chloride. With eight years of experience serving clients, we know the ins and outs of MgO boards.

Sulfycor delivers multipurpose MgO boards. All the material meets ISO standards therefore, it is safe to use.

We’ve happy clients in more than 20 countries, which motivates us to improve our procedure.

Are you prepared to make a purchase and sleep easy?

Contact us at our phone numbers or social media handles for quick responses. Door-to-door customer care is like icing on the cake. Our service is available 24/7.

Conclusion

Green building doesn’t have to be a complex undertaking.

Building industry specialists can significantly improve environmental well-being by adopting MgO boards. Thus, when organizing a project in the future, think about the potential of MgO boards. They are green solutions that provide outstanding performance without harming the environment.