10 Dec What Kind Of Board Is Used For Subfloors

Table of Contents

You can pick from many types of boards for subfloors. The most commonly used ones are plywood, OSB, particle board, magnesium board, concrete panels, and high-performance panels. Plywood is the safest choice for most jobs. Contractors prefer plywood because it is strong and flexible. It also resists water and has a natural appearance. Recently, more builders have been using OSB. They appreciate it because it is better for the environment and incorporates new technology. When selecting a board for subfloors, consider water resistance and the required strength. Ensure that the board is compatible with your finished floor. Always check local regulations and choose what best fits your project.

Key Takeaways

Plywood is strong and flexible. It does not get damaged by water easily. That is why it is a good choice for subfloors.

OSB costs less than plywood. It can swell if it gets wet. It does not hold screws as well as plywood.

Do not use particle board for subfloors in wet places. It can bend and get weak after some time.

Magnesium board and concrete panels work well in wet areas. They do not get damaged by water. They last a long time.

Always look at local building codes before you choose a subfloor. Think about what your floor needs before you pick a material.

Plywood Subfloor Boards

Plywood Features

Plywood is a safe and trusted choice for subfloors. Builders like plywood because it is strong and does not bend easily. You can pick from many grades and thicknesses for your needs. Most building codes say to use C-D grade plywood. The thickness should be 3/4-inch or 5/8-inch. Tongue-and-groove plywood is good for tile or stone floors. The edges lock together and help keep the floor steady. CDX plywood can handle some water, so it works in places with spills or humidity.

Tip: Tongue-and-groove plywood spreads weight out and keeps your floor flat.

Here is a quick comparison of how plywood and OSB work:

Attribute | Plywood | OSB |

|---|---|---|

Structural Strength | Strong and stiff | Not as strong |

Moisture Resistance | Usually does not swell | Edges swell when wet |

Suitability for Flooring | Good for all flooring | Not good for tile or stone |

Nail/Screw Holding Power | Holds nails and screws well | Does not hold as well |

Durability | Lasts a very long time | Lasts a very long time |

Best for Heavy Flooring | Best for heavy flooring | Not best for heavy flooring |

Pros and Cons

Plywood has many good points for subfloors. It does not swell as much as OSB when wet. Nails and screws stay tight in plywood. Plywood lasts for many years and can hold heavy floors. But plywood costs more than OSB or particle board. Regular plywood does not resist water as well as CDX or tongue-and-groove plywood. You need to pick the right type for wet areas.

CDX plywood can handle some water but is not waterproof.

Tongue-and-groove plywood is steady in wet places.

Regular plywood is best for dry rooms.

Best Uses

You can use plywood subfloors in almost any room. Kitchens, bathrooms, and laundry rooms need CDX or tongue-and-groove plywood. These boards stay strong and do not get damaged by water. Living rooms and bedrooms do well with regular plywood. If you want to put in tile or stone, use ¾” tongue-and-groove plywood. Plywood is a good choice for any subfloor where you want strength and long life.

OSB and Particle Board Subfloors

OSB Features

You may see osb used often as a subfloor in new homes. Builders choose osb because it costs less than plywood and comes in large sheets. Osb stands for Oriented Strand Board. Manufacturers make it by pressing wood strands together with glue. Osb works well for subflooring, wall sheathing, and roof panels. You can use osb as a subfloor under carpet, vinyl, or laminate. Osb is one of the common subfloor materials in modern construction.

Osb swells more than plywood when it gets wet. The edges may stay swollen and lose their shape.

Plywood can shrink back after drying, but osb often stays deformed.

Osb does not hold screws and nails as tightly as plywood. You may notice more squeaks and bounce in high-traffic areas.

Osb usually lasts about 30 years if you keep it dry. Plywood can last over 50 years.

Particle Board Overview

Particle board is another option for subfloor, but you should know its limits. Manufacturers make particle board by pressing wood chips and glue into sheets. Particle board costs less than plywood and osb, but it does not perform as well.

Particle board swells and warps when exposed to moisture.

The porous surface lets water in, which can lead to mold and mildew.

Particle board has weak load-bearing strength. Heavy furniture or busy areas can cause it to crack or break.

Screws and nails do not stay tight in particle board. Floors may feel unstable.

Pros and Cons

You may want to compare osb and particle board to plywood before you choose a subfloor. Plywood is a traditional subflooring material with better long-term performance.

Material | Cost | Durability | Moisture Resistance | Screw/Nail Holding | Lifespan |

|---|---|---|---|---|---|

Plywood | High | Excellent | Good | Excellent | 50+ years |

OSB | Medium | Good | Fair | Fair | ~30 years |

Particle Board | Low | Poor | Poor | Poor | <20 years |

Osb offers a budget-friendly choice for subfloor, but you must protect it from water.

Particle board is less ideal for subfloor because it swells, warps, and breaks easily.

Tip: Avoid using particle board in kitchens, bathrooms, or laundry rooms. Even small spills can damage the subfloor.

Suitable Applications

You can use osb for subfloor in dry areas like bedrooms or living rooms. Osb also works for wall and roof sheathing. Particle board is best for furniture, not for subfloor. If you want a strong and long-lasting subfloor, choose plywood or osb. Reserve particle board for low-traffic spaces where moisture is not a concern.

Magnesium Board and Concrete Panels

Magnesium Board Overview

Magnesium Board Overview

Magnesium board, or MgO board, is good for wet places. It does not let water, mold, or mildew in. You can use it in bathrooms, kitchens, basements, and homes near the ocean. Magnesium board helps keep the air inside your house clean. It also stops mold from causing problems. If you want a strong subfloor for wet spots, magnesium board is a smart pick.

Tip: Magnesium board will not burn, so it makes your home safer from fire.

Here is a simple chart to show how magnesium board, plywood, and OSB compare:

Material | Fire Risk | Flame Resistance | Water Resistance | Mold Resistance |

|---|---|---|---|---|

MgO Boards | None | High | High | High |

OSB | High | Low | Low | Low |

Plywood | High | Low | Low | Low |

Concrete Panel Features

Concrete panels make a subfloor that is strong and steady. They can hold heavy things and do not bend or break fast. Use concrete panels in places that need extra strength. Basements, bathrooms, or rooms with tile or vinyl floors are good spots. Concrete panels also keep out water and fire. This makes them a safe choice for many homes.

Material | Strength & Load Bearing | Typical Applications |

|---|---|---|

Concrete Slab | Superior hardness and stability; excellent load support | Best for tile, vinyl, and moisture-prone areas like basements and bathrooms |

Cement Boards | Strong and durable; supports tile well | Ideal for wet areas, tile underlayment, fire-resistant applications |

Pros and Cons

Magnesium Board Pros:

Keeps out water, mold, and mildew

Very good at stopping fire

Makes indoor air better

Easy to put in with screws or glue

Magnesium Board Cons:

Costs more than wood boards

Can break if not handled with care

Concrete Panel Pros:

Very strong and steady

Can hold heavy things

Works well in wet places

Concrete Panel Cons:

Heavy and hard to cut

Takes more time and work to install

When to Use

Pick magnesium board for subfloors in wet or damp places. Bathrooms, kitchens, basements, and homes near water are good choices. Concrete panels are best when you need a tough subfloor for tile or vinyl. They work well in wet or busy rooms. Both help you build a floor that is safe and lasts a long time.

Comparing Board for Subfloors

Key Differences

Key Differences

There are many boards you can use for subfloors. Each board has good and bad points. The table below shows how each board compares. It lists cost, durability, and how well they handle water.

Subfloor Material | Installed Cost per Sq.Ft. (USD) | Durability | Moisture Resistance | Maintenance Needs |

|---|---|---|---|---|

Plywood | $2.75 – $6 | Good | Low | Moderate |

OSB | $2.50 – $4.50 | Fair | Low | Moderate |

MgO Board | $$ | Excellent | High | Low |

Particle Board | $ | Poor | Very Low | High |

Concrete | $$ | Excellent | High | Low |

Plywood and osb do not cost much. They are easy to use. MgO board and concrete panels last longer and keep out water. They cost more and need experts to install. Particle board is the cheapest. It does not last long and gets ruined by water.

Choosing the Right Subfloor

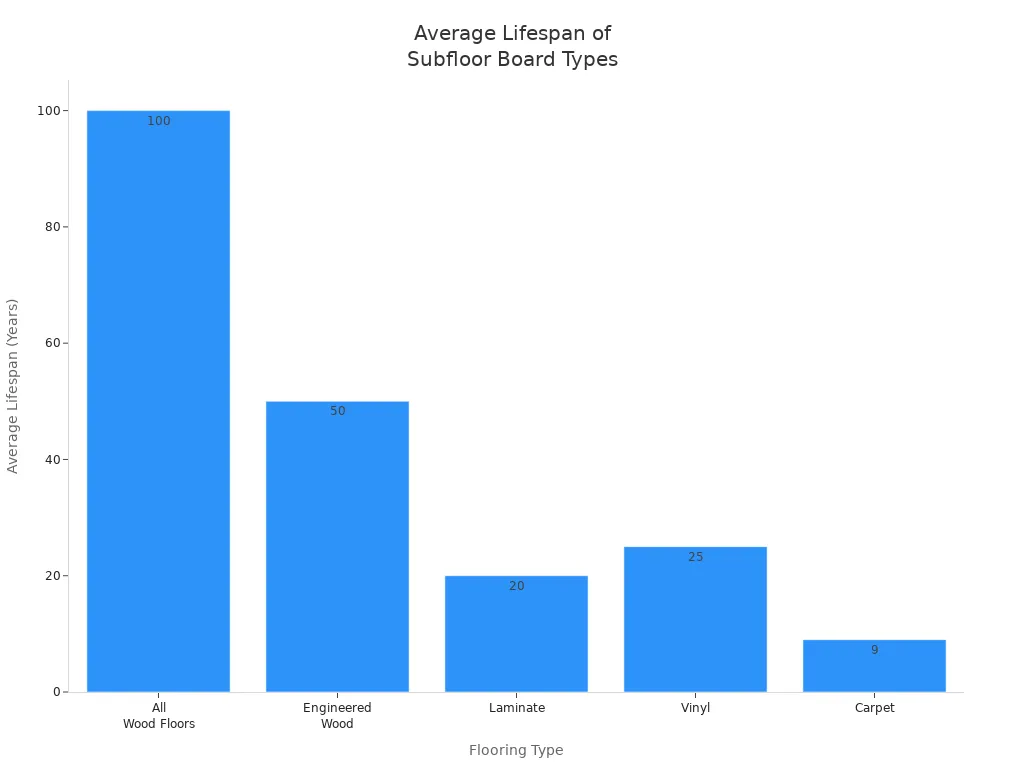

Think about your room before you pick a board. Also, think about your finished floor. Plywood works well for hardwood, carpet, and engineered wood. Osb can hold these floors too, but it does not stop water as well. For tile, use plywood or osb with cement board under it. MgO board and concrete panels are best for wet rooms like bathrooms and basements. The chart below shows how long each board lasts under different floors.

Tip: Put a moisture barrier under concrete or MgO board. This gives extra protection.

Installation and Maintenance Tips

You can help your subfloor last longer by doing things right. Take out old flooring before you start. Fix rough spots so the new boards sit flat. Stagger the joints to make the floor stronger. Cut edges with a saw so they are neat. Use screws or glue to hold panels down. Make sure the glue is still wet when you press the boards. Let boards sit in the room before you add the finished floor. Check for moisture and use a vapor barrier if you need it. Fill gaps and sand rough spots to keep the floor smooth. Pick the right thickness so your floor does not squeak or feel weak.

Common mistakes are using the wrong screws, skipping moisture protection, and not letting boards get used to the room. You can stop problems by following these steps.

Choosing the right board for your subfloor helps you avoid squeaks, sinking floors, and costly repairs. You often find plywood as the safest choice because it lasts long and meets most building codes. Magnesium board and concrete panels work well in wet areas. When you compare plywood and OSB, plywood costs more but gives better durability. Always check that your subfloor meets local regulations. If you want the best results, talk to a flooring professional. Their advice helps you match plywood or other boards to your project.

Remember: Using plywood instead of chipboard prevents loose boards and squeaks.

Plywood: $21.50 per sheet (3/4 inch)

OSB: $16.50 per sheet (3/4 inch)

FAQ

What thickness should you use for a subfloor?

You should use 3/4-inch thick plywood or OSB for most homes. This thickness gives strong support and helps prevent floor flexing. Always check your local building codes for exact requirements.

Can you use particle board as a subfloor?

You should avoid particle board for subfloors. It swells and weakens when wet. Floors may feel soft or unstable. Use plywood or OSB for better strength and durability.

How do you protect your subfloor from moisture?

You can install a vapor barrier under your subfloor. This helps block water from reaching the boards. Use moisture-resistant boards like CDX plywood or MgO board in wet areas.

Tip: Always fix leaks quickly to keep your subfloor dry.

Which subfloor works best under tile?

You should use tongue-and-groove plywood or a concrete panel under tile. These boards give a flat, stable base. Add a cement board layer for extra support and water resistance.

Can you install new subfloor over old flooring?

You can install new subfloor over old flooring if the surface is flat and dry. Remove damaged or loose boards first. This helps your new floor last longer and stay strong.

Magnesium Board Overview

Magnesium Board Overview Key Differences

Key Differences