28 Aug Explaining ASTM E119 Fire Safety Standards for Magnesium Wall Panels

Table of Contents

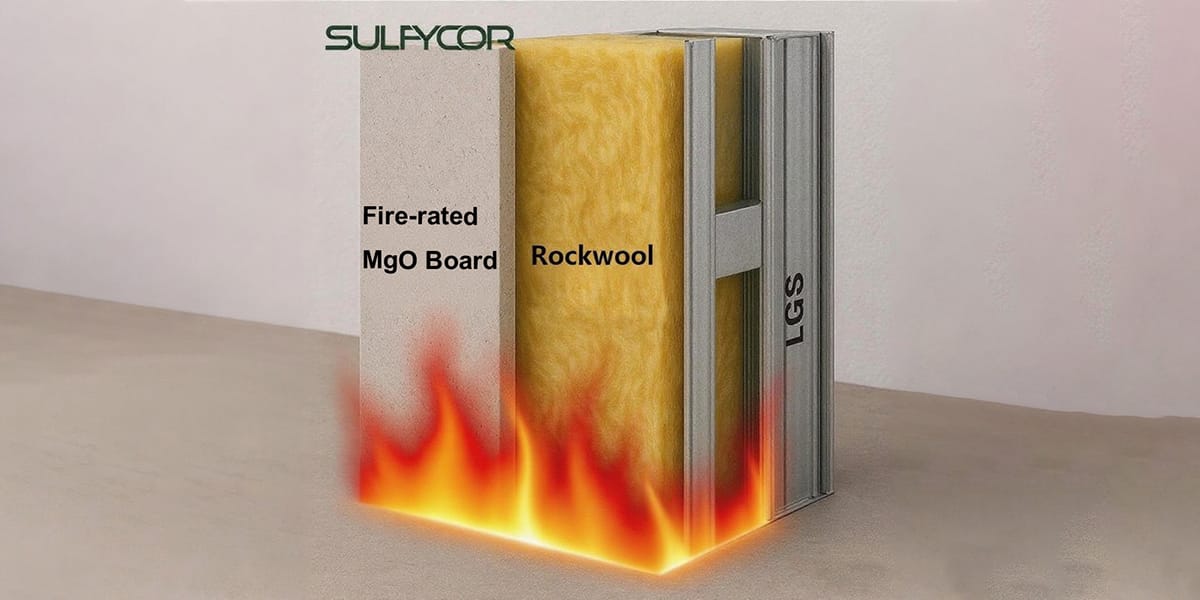

ASTM E119 gives a clear rule for fire resistance in building materials. Magnesium wall panels have to meet tough rules to keep people safe during a fire. Builders and inspectors use these standards to make sure magnesium panels protect well. Fire resistance and following the rules are very important in building today. These things help keep people and buildings safe.

Key Takeaways

ASTM E119 checks how long materials can fight fire and stay strong. Magnesium oxide panels can handle very hot heat. They do not burn and make little smoke. This makes them safer than gypsum or cement boards. MgO panels stay strong when there is a lot of weight in fires. They also resist water, mold, and damage. This helps buildings last longer. Using MgO panels helps builders follow fire safety rules faster. It can also lower insurance costs because of better fire protection. Picking magnesium oxide panels makes buildings safer. It lowers repair costs and helps people escape fires more safely.

ASTM E119 Overview

Purpose

ASTM E119 tells us how to check if building parts can stand up to fire and stay strong. This test helps people like architects and engineers know if a wall, floor, or roof will keep people safe in a fire. The main idea is to find out how long a wall panel, like magnesium oxide (MgO), can stop fire from spreading and keep its shape. This rule helps builders follow safety codes and build safer places.

ASTM E119 does not look at just one material. It checks whole things like walls or partitions when there is a fire. The results show how long the wall can hold back fire and keep its shape.

Test Criteria

The ASTM E119 test uses strict steps to see how well something resists fire. The test puts wall panels in a furnace with a controlled fire. Experts check how much heat goes through, if flames get past, and if the wall stays strong. If the wall holds weight, the test also checks if it can still hold up during a fire. After the fire, some panels get sprayed with water to act like firefighters.

Key Requirements | Test Procedures and Criteria | |

|---|---|---|

Loadbearing Walls and Partitions | Minimum 100 ft² surface, no vertical edge restraint | Must hold applied load; no flame passage; pass hose stream test; limit heat on unexposed side |

Non-Loadbearing Walls and Partitions | Minimum 100 ft² surface, restrained on all edges | Must stop flame passage; pass hose stream test; limit heat and openings |

Floors and Roofs | Minimum 180 ft² surface, size limits | Must hold load; limit temperature rise; check steel and concrete temperature |

Protective Membranes | Must meet wall/floor/roof criteria | Limit temperature rise on thermocouples |

The test stops when the wall cannot block fire, loses strength, or lets in too much heat. Ratings like “one-hour” or “two-hour” tell us how long the wall lasted in the fire.

Relevance to MgO Panels

Magnesium oxide panels do very well in ASTM E119 tests. These panels can take heat over 1,382°F for a long time without changing color or getting weak. When there is a fire, MgO panels let out water vapor, which cools things down and slows the fire. They also make very little smoke and do not let flames spread much, so they are good for places like hospitals and schools. MgO panels have certificates that show they meet or beat ASTM E119 rules, so they are good for fire-rated walls.

MgO panels often do better than other fire safety rules. Their strong fire resistance and ability to stay together make them a good choice for new buildings.

Fire Resistance

Ratings

Magnesium oxide wall panels get high fire resistance scores in safety tests. Makers build these panels to last a long time in fire. In ASTM E119 tests, 1/2-inch MgO panels show 1-hour and 2-hour fire resistance. These panels do not burn, even at very high heat close to 2200°F. The panels meet Class A fire rating rules and pass ASTM E136 for noncombustibility. Builders use these ratings to pick materials that keep people and buildings safe in a fire.

MgO panels keep their fire resistance in real-life fires. They can stop flames and heat, so they work well in hospitals, schools, and big apartment buildings.

Structural Integrity

It is important for panels to stay strong during a fire. Magnesium oxide wall panels go through tough tests to make sure they hold up under weight. In ASTM E119 tests, panels with glass fiber mesh stay strong under heavy loads. Some panels can hold up to 10,000 pounds without bending or breaking. Makers say these panels are safe for outside walls, even in tall buildings over 40 feet. The panels do not get damaged by water, do not bend, and do not fall apart, so they last longer.

Panel Type | Fire Resistance Rating | Structural Load Capacity | Durability Features |

|---|---|---|---|

1-hour, 2-hour | Up to 10,000 pounds | Moisture, warp, and corrosion resistant |

New magnesium oxide technology makes panels better at handling heat and fire. Makers use special materials and nanotechnology to make them stronger. Some panels have mineral wool and ceramic parts, which help them stay strong in heat, about 30% better than gypsum boards. These new panels can keep up to 94% of their strength after 2 hours in fire.

Flame Spread

Flame spread shows how fast fire moves on a surface. Magnesium oxide panels do very well in these tests. In ASTM E84 tests, MgO panels get a flame spread index under 25, which is Class A. The panels do not catch fire and make very little smoke. Less smoke helps people get out safely during a fire.

Test Standard | Flame Spread Index | Smoke Development | Temperature Resistance |

|---|---|---|---|

ASTM E84 | Very low | Up to 1472°F (800°C) |

MgO panels do not burn or help fire spread.

The panels stay safe and strong, even in hot places.

Builders use MgO panels in fire-rated walls to lower risk and make buildings safer.

Magnesium oxide wall panels follow strict fire safety rules. They do not burn and make little smoke, so they are a good choice for new buildings.

Material Comparison

MgO vs. Gypsum

MgO vs. Gypsum

Magnesium oxide (MgO) panels are much better at stopping fire than gypsum boards. MgO boards do not burn. They can handle very high heat, so they are great for fire-rated walls. MgO panels can last up to 4 hours in a fire. Gypsum boards, even the fire-rated ones, usually last only 30 minutes to 1 hour. This means MgO panels keep buildings safe for a longer time during a fire.

EXACOR MgO panels have special certificates from other companies. These show they are strong against fire and do not let flames spread. This makes them a good pick for big apartment buildings and stores. Gypsum boards are used a lot, but they do not work as well as MgO panels in a fire.

Smoke is another big difference between these materials. MgO panels make very little smoke in fire tests. Gypsum boards make more smoke, which can make it hard to see. The table below shows how MgO and gypsum boards are different:

Criteria | Magnesium Oxide (MgO) Panels | Gypsum Boards |

|---|---|---|

Fire Resistance Duration | Up to 4 hours | 30–60 minutes |

Smoke Development | Very low | Moderate, more visible smoke |

Flame Spread | Minimal | Moderate |

Combustibility | Non-combustible | Combustible |

MgO vs. Cement Board

MgO panels are also better than cement boards when it comes to fire safety. MgO panels can take heat up to 1,472°F (800°C) and stay strong in a fire. They do not crack or break, even when stressed. Cement boards can stop fire, but usually only for up to 2 hours. They may crack or get damaged during a fire.

Property/Characteristic | MgO Boards | Cement Boards |

|---|---|---|

Fire Resistance Rating | Up to 4 hours | Up to 2 hours |

Structural Integrity under Fire | Maintains strength | Prone to cracking |

Combustibility | Non-combustible | Fire-resistant |

Smoke Emission | Minimal | Low |

Benefits

Magnesium oxide panels have many good points over other building materials:

Superior Fire Resistance: MgO panels pass tough fire safety tests like ASTM E119 and ASTM E84. They do not burn or help fire spread.

Low Smoke and Toxicity: These panels make almost no smoke or bad gases, so it is safer to leave the building.

Strength and Durability: MgO panels are strong. They do not break easily, get wet, or grow mold. They last longer than gypsum or cement boards.

Environmental Safety: MgO does not have harmful chemicals and can be recycled.

Long-Term Value: MgO panels cost more at first, but they last over 60 years. They can also help lower insurance costs because they are so safe in a fire.

Builders and owners pick MgO panels because they are safer, stronger, and more dependable for fire-rated buildings.

Building Applications

Compliance

Compliance

Building codes say walls must be very fire-resistant. Magnesium wall panels that pass ASTM E119 help builders follow these rules. Many code officials want to see certifications, like ICC-ES, to prove panels passed fire tests. These papers help builders get their projects approved faster.

ASTM E119 checks the whole wall, not just the panel, to make sure it can stop fire and hold weight for a certain time.

MgO panels such as EXACOR™ have ratings that meet or go above what codes need, so builders can use fewer layers or less material.

Following ASTM E119 can make getting approval quicker and give designers more options.

Using tested panels can help save money on work and materials.

Tip: Builders should always look for the latest certifications and test reports before picking wall panels.

Safety Implications

Magnesium wall panels that meet fire safety rules help protect people and buildings. These panels stay strong in a fire and do not burn or make bad smoke. The table below shows important safety features:

Feature/Property | Description/Result |

|---|---|

Fire Resistance | Stays strong for up to 2 hours |

Combustibility | Does not burn |

Smoke and Flame | 0/0 rating for flame spread and smoke |

Heat Resistance | Handles up to 1200°F |

Fire Safety Classification | Meets Class A rules |

Extra Benefits | Fights moisture, mold, and pests |

Putting panels in the right way and checking them often helps them work as a fire barrier. Builders, code officials, and owners should look for damage and keep panels clean.

Insurance Considerations

Insurance companies may give better prices to buildings with good fire safety. Magnesium wall panels that pass ASTM E119 can help lower insurance bills. These panels slow down fire and keep the building safe, so insurance companies worry less. Owners also get faster building times, fewer delays, and less fixing. Sometimes, using MgO panels has saved a lot of money and made projects finish sooner.

Note: Picking panels with strong fire resistance can save money over time and make buildings safer.

Magnesium oxide wall panels that meet ASTM E119 are very good at stopping fire. These panels keep fires from spreading fast. They help people get out safely in big apartment buildings. The table below shows MgO panels cost less to fix over time than drywall. This is because MgO panels are strong and do not get damaged by water, mold, or bugs. Builders and owners should pick panels that are tested and follow the rules. This helps keep everyone safe and saves money later.

Feature/Aspect | Magnesium Oxide Board (MgO) | Drywall (Gypsum Board) |

|---|---|---|

Fire Resistance | Withstands 2-3 hours of high heat | Less fire resistant |

Long-Term Cost | Lower (up to 55% savings over lifecycle) | Higher (frequent repairs needed) |

Mold/Moisture Resistance | High | Low |

FAQ

What does ASTM E119 mean for magnesium wall panels?

ASTM E119 shows how long magnesium wall panels can stop fire and stay strong. Builders use this test to prove panels meet safety codes. The test helps people trust the panels in schools, hospitals, and homes.

Are magnesium oxide panels noncombustible?

Yes. Magnesium oxide panels do not burn. They pass ASTM E136 for noncombustibility. This means they help stop fire from spreading and keep buildings safer.

How do MgO panels compare to drywall in fire safety?

Feature | MgO Panels | Drywall |

|---|---|---|

Fire Resistance | Up to 4 hours | 30–60 minutes |

Smoke | Very low | Moderate |

MgO panels last longer and make less smoke during a fire.

Can builders use MgO panels for exterior walls?

Builders can use MgO panels for both interior and exterior walls. These panels resist water, mold, and pests. They stay strong in wet or hot weather, making them a good choice for many building types.

MgO vs. Gypsum

MgO vs. Gypsum Compliance

Compliance