Our precision-engineered mixing process ensures the perfect blend of magnesium oxide and other essential components. This meticulous mixing guarantees the superior quality and consistency of our MGO boards.

Production Process Vlog 1

Using state-of-the-art equipment, we carefully shape and form the mixture into boards, then gently demould them to prevent any damage to the delicate structure. This process ensures the integrity and strength of our MGO boards.

Production Process Vlog 2

Our advanced cutting technology allows us to precisely size our boards to meet your specific requirements. After cutting, the boards undergo a thorough curing process to enhance their durability and dimensional stability. This ensures that our MGO boards are ready for your construction needs, delivering exceptional performance and reliability.

Production Process Vlog 3

About us

Professional Magnesium Oxide Board Manufacturer,Offer All Types of Mgo Board SolutionProfessional Magnesium Oxide Sulfate Board (Chloride-free Mgo board) Manufacturer. Sulfycor founded in 2015 , stands as a leader in the MGO board industry. Spanning over 50,000 square meters, The average daily production capacity is 30,000 square meters. Holding certifications and patents for our entire product range, we’ve garnered a global clientele from 20+ countries and regions.

At Sulfycor, Mgo board products boast industry-leading technical specifications and performance capabilities. From fireproof boards to various MGO board solutions, we consistently pioneer excellence in both product quality and innovation.

Learn More About Production

Magnesium Oxide Board Used For

Exterior Wall Sheathing

A high-performance exterior cladding material designed for durability and weather resistance, ideal for enhancing building envelope protection.

Interior Wall Board

A safe, eco-friendly interior partitioning material with excellent fire resistance and moisture resistance, suitable for residential and commercial spaces.

MgO Board Subfloor

A stable, load-bearing underlayment material that provides a solid base for flooring, featuring mold resistance and structural integrity.

Decorative Wall Board

A versatile decorative surface material available in various finishes, combining aesthetic appeal with fire and moisture resistance for interior design.

Quality You Can See

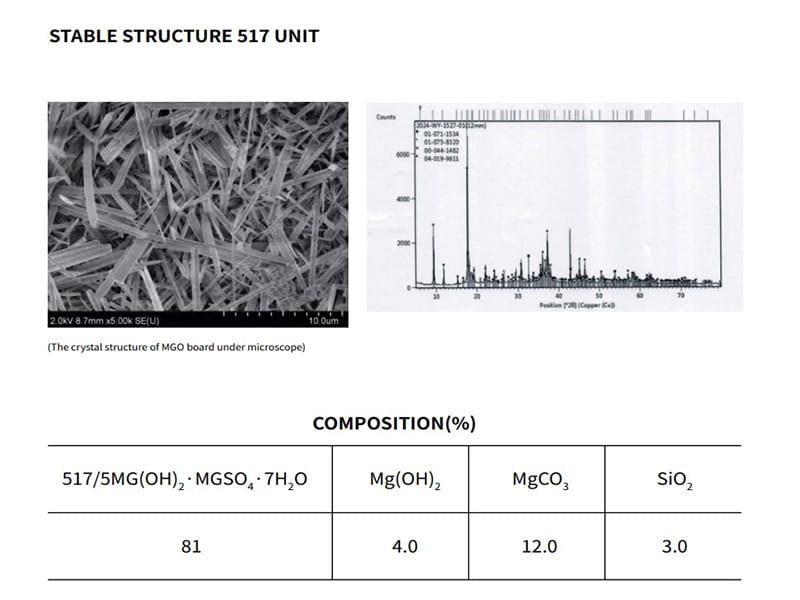

To deliver exceptional Magnesium Oxide Boards(MgSO4), we adhere to strict practices at every stage.

* Perfect Raw Material Formula:

Our Magnesium Oxide boards are made primarily from Magnesium Sulfate, avoiding the halogenation issues that can occur with traditional magnesium oxide boards that use magnesium chloride materials. Careful formulation ensures uncompromised quality.

* Precise Production Supervision:

From material mixing to board production to the curing of the magnesium oxide boards, strict process management is executed throughout the manufacturing process to ensure consistent product quality. This includes oversight of the magnesium sulfate chemical composition and crystal reactions (MgSo4 BMSC 517 phase) to ensure perfection.

* Pre-Delivery Quality Inspection:

Before reaching our customers, our products undergo rigorous quality checks to ensure that each board meets our stringent standards. This comprehensive assessment guarantees that we only deliver high-quality boards.

Get More About Our Factory

Daily Production Capacity: 30,000 SQM

Operating at peak efficiency, our state-of-the-art factory has the capability to churn out a staggering 30,000 square meters of standard MGO boards every single day. This immense production capacity ensures that we can fulfill your orders with unparalleled speed and efficiency.

Production Facilities Exceeding 50,000 SQM

Our production base encompasses over 50,000 square meters, enabling us to handle all aspects of MGO board production, grooving, surface treatments, and more. As one of the few domestic MGO manufacturers offering comprehensive one-stop solutions, we are committed to meeting our clients’ diverse needs.Discover Our Customer Success Stories

Request a Free Sample Or Get a Customized Quote Now!

Let us help you find the perfect solution for your project.