05 Feb What is Magnesium Sulfate Subfloor and Why Choose It

Table of Contents

You might wonder why magnesium sulfate subfloor is a great building material. Magnesium sulfate subfloor uses sulfate magnesium board. This board is very good at stopping fire. It also does not get damaged by water easily. It is good for the environment too. When you pick this strong material, you help save resources and support green building. Builders like magnesium sulfate boards because they last a long time and are good for the planet. The table below shows how magnesium sulfate subfloor is different from plywood:

Criteria | Magnesium Sulfate Subfloor | Plywood |

|---|---|---|

Moisture Resistance | Highly resistant | Swells or warps |

Fire Resistance | Non-combustible | Limited |

Durability | Very durable | Less resistant |

Environmental Impact | Eco-friendly | Not sustainable |

More builders are picking magnesium sulfate subfloor because of the good things about mgo subfloor panels.

Key Takeaways

Magnesium sulfate subfloor is very good at stopping fire and water. This makes it a safe pick for many buildings.

These boards are good for the environment. They use less stuff and help lower your carbon footprint a lot.

It is fast and simple to install them. You only need basic tools. This helps builders save time and work.

Magnesium sulfate boards last a long time and do not need much care. This means you spend less money over time and do not fix them often.

They block noise well and keep heat in. This helps make rooms more comfy inside.

Magnesium Sulfate Subfloor Overview

What is Magnesium Sulfate Subfloor

Magnesium sulfate subfloor is used in lots of new buildings. It has magnesium sulfate board as the main part. This board makes floors strong and safe. Builders pick these boards because they stop fire and water. You can put them in homes, schools, and offices. These boards help keep buildings safe and dry.

Composition and Structure

Magnesium sulfate boards are made from different materials. Each material helps the board work better. See the table below to learn what is inside and how it helps:

Component | Contribution to Performance |

|---|---|

Magnesium oxide (MgO) | Forms the base of the board, providing structural integrity. |

Magnesium sulfate (MgSO₄) | Acts as a key binding agent, enhancing adhesion. |

Wood dust or cellulose | Adds flexibility and texture to the board. |

Perlite or vermiculite | Improves insulation and fire resistance. |

Glass fiber mesh | Increases strength and durability of the board. |

Glass fiber mesh is found in the board. This mesh makes the board strong and hard to break. Magnesium and oxygen stick together tightly. This makes the board tough if it gets hit. The subfloor does not bend, swell, or rot when wet. The sulfate in the board helps steel frames not rust. It is also good for the environment.

How MgSO4 Boards Work

MgSO4 boards help support floors in a special way. Magnesium sulfate and magnesium oxide mix and make strong crystals. These crystals make the board last a long time and keep out water. The subfloor stays strong even in wet places. The sandwich layers make the board even stronger. You can use mgo subfloor panels in many buildings. They work well in wet rooms and places that need fire safety. You get a safe, steady, and tough floor base.

Magnesium Sulfate Boards Advantages

When you check the advantages of magnesium sulfate boards, you can see why builders like to use them in new buildings. These boards stop fire, water, and mold. They are strong and last a long time. They are also good for the planet. They block sound and help keep rooms warm or cool. Let’s look at each benefit to see how magnesium sulfate boards make your building better.

When you check the advantages of magnesium sulfate boards, you can see why builders like to use them in new buildings. These boards stop fire, water, and mold. They are strong and last a long time. They are also good for the planet. They block sound and help keep rooms warm or cool. Let’s look at each benefit to see how magnesium sulfate boards make your building better.

Fire and Moisture Resistance

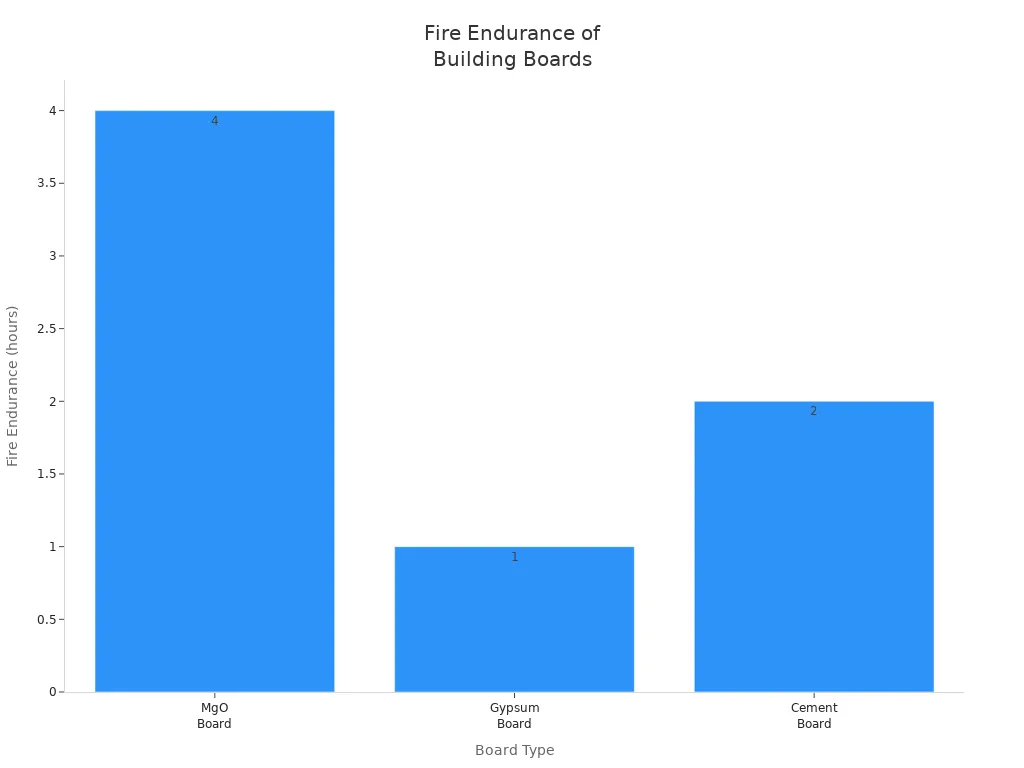

You want your subfloor to keep your building safe from fire and water. Magnesium sulfate boards are great at stopping fire. They do not burn or help fire spread. You can feel safe because these floors can handle high heat for many hours. The table below shows how magnesium sulfate boards, plywood, cement board, and gypsum board compare for fire resistance:

Property/Material Aspect | Magnesium Oxide (MgO) Boards | Plywood | Cement Board | Gypsum Board |

|---|---|---|---|---|

Fire Resistance | Superior, up to 4 hours | Variable; requires fireproofing | Up to 2 hours | Up to 1 hour |

Combustibility | Non-combustible | Combustible | Non-combustible | Non-combustible |

Temperature Resistance | Withstands up to 800°F | Vulnerable to heat | Withstands up to 600°F | Withstands up to 350°F |

Fire Spread | Does not contribute | Catches fire easily | Does not contribute | Does not contribute |

Magnesium sulfate boards also keep out water. You do not need to worry about swelling, bending, or rotting. The table below shows how different subfloor materials deal with water:

Subfloor Material | Moisture Resistance | Durability |

|---|---|---|

Magnesium Oxide Panel | Excellent | Excellent |

Cement Board | Excellent | Excellent |

Engineered Wood Panel | Good | Good |

Premium OSB | Very Good | Very Good |

Waterproofed Plywood | Good | Good |

Standard Plywood | Fair | Fair |

OSB | Fair | Fair |

Magnesium sulfate boards let water vapor pass through. This means your floors dry fast and stay strong, even in wet places. These panels help you control water and mold better than most other materials.

Strength and Durability

You need floors that last and can handle daily use. Magnesium sulfate boards are very strong and tough. These panels have flexural strength between 12 and 18 MPa. You can count on them to hold heavy things and take hits. The glass fiber mesh inside makes the boards even stronger.

Impact resistance: 5 kJ/m² (higher than cement boards at 2.32 kJ/m²)

Material | Impact Resistance (kJ/m²) |

|---|---|

Magnesium Oxide | 5 |

Cement Boards | 2.32 |

Your subfloor will not crack, bend, or break easily. Magnesium sulfate boards last a long time and give strong support for any building.

Eco-Friendly Benefits

If you care about the earth, magnesium sulfate boards are a good choice. These panels use less energy and fewer resources than plywood or cement board. They have biochar, which helps them trap carbon and makes them carbon-negative.

They make less carbon dioxide when made.

Biochar in the boards traps carbon, which is good for the planet.

You help the earth when you pick magnesium sulfate boards. Their eco-friendly parts and benefits make them a smart pick for people who want to lower their carbon footprint.

Mold and Impact Protection

You want floors that stay clean and safe. Magnesium sulfate boards do not let mold, mildew, or fungus grow. Their inorganic parts and high alkalinity stop mold, even in damp places. The table below shows how magnesium sulfate boards protect against mold:

Evidence Type | Description |

|---|---|

Inorganic Composition | MgO boards do not provide a food source for mold, preventing growth. |

Moisture Absorption | MgO boards absorb only 0.34% moisture, compared to 3% for gypsum boards. |

Alkalinity | High alkalinity of MgO boards inhibits microbial growth. |

ASTM G21 Test | MgO sheathing scored 0/0/0, indicating complete mold resistance. |

You get better air and a healthier space. Magnesium sulfate boards also protect against dents and damage. These panels keep your floors looking new for a long time.

Made from inorganic materials, so mold cannot grow.

Great for wet and humid places.

High impact resistance keeps floors safe from heavy use.

Acoustic and Thermal Performance

You want your building to be quiet and comfy. Magnesium sulfate boards block noise and help keep rooms warm or cool. These panels have Sound Transmission Class (STC) ratings of 53 to 54. This means less sound moves between rooms and floors.

STC rating: 53–54 (great sound insulation)

Dense structure blocks sound and lowers noise

Magnesium sulfate boards help save energy. You spend less money on heating and cooling because these panels help keep the indoor climate steady. You make your building peaceful and comfortable for everyone.

Tip: Magnesium sulfate boards give you fire resistance, water and mold resistance, strength, eco-friendly benefits, and good sound and heat control. You get a safer, greener, and more comfortable building when you use these panels.

Magnesium Sulfate Board vs Other Materials

Plywood and OSB Comparison

Plywood and OSB Comparison

Magnesium sulfate board is safer and lasts longer than plywood and OSB. It does not burn or swell when wet. Plywood and OSB can catch fire and bend if they get wet. You want a subfloor that stays strong in any weather.

Feature | Magnesium Sulfate Boards (MgO) | Oriented Strand Board (OSB) |

|---|---|---|

Excellent; non-porous, stable | Poor; absorbs water, swells | |

Fire Resistance | Naturally noncombustible | Requires chemical treatments |

Cost per Square Foot | $1.50 – $3.00 | $0.50 – $1.00 |

Installation Ease | Requires precision, lightweight | Simple, lightweight |

Magnesium sulfate board costs more, but it protects better. OSB and plywood need extra steps to fight fire and water. Magnesium sulfate board gives you these benefits without extra work.

Material | Fire Resistance | Moisture Resistance |

|---|---|---|

MgSO₄-MgO Boards | Non-combustible, withstands fire exposure without losing integrity | Stable under wet-dry cycles, resists mold and mildew |

OSB | Flammable, contributes to flame spread | Sensitive to moisture, may swell or warp |

Plywood | Flammable, contributes to flame spread | Sensitive to moisture, may lose structural strength |

Note: Magnesium sulfate board helps you avoid expensive repairs from water or fire.

Cement Board Comparison

Magnesium sulfate board is lighter than cement board. You can carry and cut it easily. Cement board is heavy and needs special tools. Magnesium sulfate board saves you time when you install it.

Board Type | Weight (per square foot) | Ease of Handling | Installation Time |

|---|---|---|---|

Magnesium Sulfate | Lighter than cement | Easier to handle | Quicker |

Cement Board | Over 2.5 pounds | Heavier, cumbersome | More time-consuming |

You can cut magnesium sulfate board with normal tools.

Cement board needs special tools to cut.

Magnesium sulfate board is faster to install because it is light.

Magnesium sulfate board is easy to move and bend.

You only need basic tools to cut and shape it.

Cement board is heavy and slows down your work.

Performance and Practical Benefits

Magnesium sulfate board gives you a strong and safe subfloor. It protects against fire, water, and damage. You spend less on fixing and keeping it up. The board also helps save energy, so heating and cooling cost less.

Great fire resistance with a flame-spread index of zero.

Stops water damage, so you pay less for repairs.

Tough and strong for bad weather.

Helps keep rooms warm or cool.

Magnesium sulfate board is strong and good for the planet. It lasts longer and helps you build safe, green places. You save time and money because you do not need extra layers or finishing. You can paint it right away, which makes your job faster.

Magnesium sulfate board helps your building last longer.

It costs less over time than gypsum.

You do not need extra backing or finishing steps.

Tip: Magnesium sulfate board gives you a safer, stronger, and cheaper subfloor for your building.

Applications and Suitability of MgSO4 Boards

Residential and Commercial Use

Residential and Commercial Use

You can use magnesium sulfate boards in many places. These boards work well in both homes and commercial buildings. You will find them in apartments, offices, schools, and hospitals. The applications of magnesium sulfate boards include subfloors, wall panels, and ceilings. You get strong support for heavy furniture and equipment because of their high load capacity. Many builders choose these boards for their easy installation and long-lasting performance.

Tip: You can use these boards in new buildings or when you remodel old spaces. Their easy installation saves you time and effort.

Wet and Fire-Prone Areas

You want your floors to stay safe in wet or fire-prone areas. Magnesium sulfate boards do not absorb water, so you can use them in bathrooms, kitchens, and basements. These boards keep their shape in humid places, unlike plywood or drywall. You also get protection from mold and mildew because the boards have a very low water absorption rate.

MgO boards do not absorb water.

They keep their strength in humid conditions.

Mold and mildew cannot grow on these boards.

You get better air quality in your home.

For fire safety, magnesium sulfate boards meet top standards. See the table below for fire certifications:

Certification Standard | What It Tests | Fire Rating |

|---|---|---|

ASTM E84-24 | Handles over 750°C (1,382°F) for 30 minutes | A1 |

EN 13501-1+A1:2010 | Follows strict fire safety rules | A1 |

EN ISO 1716 | Confirms fire safety | N/A |

Most boards resist fire for 1 to 4 hours. You can trust them in kitchens, boiler rooms, and other risky areas.

Installation and Maintenance

You will find the easy installation of magnesium sulfate boards a big advantage. You can cut and fit them with simple tools. The process is quick and does not need special skills. Here is a step-by-step guide:

Step | Description |

|---|---|

1 | Clean and level the surface before you start. |

2 | Measure and cut the boards to fit your space. |

3 | Stagger the seams for extra strength. |

4 | Place the boards on joists and align them evenly. |

5 | Secure the boards with screws at the right spacing. |

6 | Leave small gaps for expansion. |

7 | Seal the edges and joints, especially in wet areas. |

8 | Check for uneven spots and fix them. |

You do not need to check or repair these boards often. They resist water and mold, so you spend less time on upkeep. Plywood and cement board need more care, but magnesium sulfate boards stay strong with little work. You get more free time and lower costs because of their durability and easy installation.

You get lots of good things when you pick magnesium sulfate subfloor. The table below shows what makes this material special:

Advantage | Description |

|---|---|

Durability | It stays strong for many years, even in hard places. |

Moisture Resistance | It keeps water out and stops damage from happening. |

Low Maintenance | You do not need to take care of it much, so you save time and money. |

Fire Resistance | It helps protect your building from fire dangers. |

Energy Efficiency | It keeps rooms comfy and helps lower your energy bills. |

Environmental Sustainability | It uses earth-friendly stuff and helps lower your carbon footprint. |

You help the earth too because these boards take away CO2 when made and can lower your project’s carbon footprint by up to 70%. You save more money over time since these boards last longer and do not need much care. If you want a safe, strong, and earth-friendly building, magnesium sulfate subfloor is a smart pick.

FAQ

What makes magnesium sulfate subfloor better than plywood?

You get stronger floors with magnesium sulfate boards. These boards resist fire and water. Plywood can swell or burn. Magnesium sulfate boards last longer and need less care.

Can you install magnesium sulfate boards in wet areas?

Yes, you can use these boards in bathrooms, kitchens, and basements. They do not absorb water. You keep your floors safe from mold and damage.

Tip: Always seal the edges for extra protection in wet rooms.

Are magnesium sulfate boards safe for indoor air quality?

You breathe easier with magnesium sulfate boards. These panels do not release harmful chemicals. They help keep your home healthy and fresh.

Feature | Magnesium Sulfate Board | Plywood |

|---|---|---|

VOC Emissions | None | Possible |

How do you cut and install magnesium sulfate boards?

You use basic tools like a saw or drill. Measure and cut the boards to fit your space. Secure them with screws. You finish the job quickly.

Use a tape measure.

Cut with a hand saw.

Fasten with screws.

Plywood and OSB Comparison

Plywood and OSB Comparison Residential and Commercial Use

Residential and Commercial Use