19 Nov A Complete Guide to Fire Resistant Sheathing for Builders

Table of Contents

Fire resistant sheathing helps keep buildings safe from fire. You need fire retardant materials to follow safety codes and protect people. Builders use these products to make flames and smoke move slower. If you install them right and know about fire ratings, you can build safer places.

Fire ratings and standards tell you how strong a material is against fire. They help you follow safety rules.

Key Takeaways

Fire resistant sheathing makes fire move slower. This gives people more time to get out if there is a fire.

Certified fire rated assemblies help builders follow safety rules. They also help builders pass building checks.

Checking and taking care of fire resistant materials keeps them working well and safe.

Picking the right fire resistant sheathing can help save money later. It can lower the cost to fix things after a fire.

Knowing fire ratings and building codes is very important. It helps you choose the best materials for fire safety.

Fire Resistant Sheathing Overview

What Is Fire Resistant Sheathing

Fire resistant sheathing helps slow down fire in buildings. It covers walls, floors, and roofs. This material works like a shield against flames. It keeps fire from spreading fast. Regular sheathing burns quickly. Fire resistant sheathing has special chemicals or layers. These make it burn much slower. LP® FlameBlock® Fire-Rated Sheathing uses a Pyrotite® layer. This layer stops flames and blocks burn-through. Using this sheathing helps you follow fire safety codes. It gives people more time to get out during a fire.

Fire resistant sheathing does not make buildings fireproof. It makes them much safer. Many new buildings use these materials. They meet strict fire protection standards. Builders pick fire resistant sheathing because it divides spaces. This limits fire damage and saves lives.

Tip: Fire resistant sheathing can handle high heat. It slows fire better than plywood or fiberboard.

Here are some common fire-resistant materials used today:

Intumescent coatings (over 35% market share)

Fire-resistant wallboard and drywall

Magnesium oxide panels

Fire retardant wood panels

Builders use over 45% of all fireproofing materials. Most are used in cities and tall buildings.

Why Builders Need Fire Protection

Fire protection keeps buildings and people safe. Fire resistant sheathing is very important for this. Without it, fire moves fast through wood walls and floors. Unprotected wood lets flames spread quickly. This makes it more dangerous for everyone inside.

Note: Covering wood with fire-resistant materials like gypsum board helps stop fire. It keeps fire from moving to other parts of the building.

Tall buildings use more things that can burn, like Cross-Laminated Timber (CLT). Without fire resistant sheathing, these buildings have higher risks in a fire. You must protect joints and surfaces with strong materials. This helps meet safety standards.

Building codes say you must use fire resistant sheathing in many places. Here is a table with some important rules:

Code Reference | Description |

|---|---|

CRC § R302 | Says you need fire-resistant materials for outside walls of homes and other buildings. |

CA Building Code for Exterior Wildfire Exposure | Says you must use fire-resistive wall assemblies, including sheathing products. |

California Fire Code | Has strict fire safety rules. These rules change how buildings are built in the state. |

You must follow these codes to pass inspections. Fire resistant sheathing helps you meet these rules and keeps your work safe.

Types of Fire Resistant Sheathing

When you pick materials for a building, you should know the main types of fire resistant wallboard. Each type protects in different ways and works best in certain spots. You can find choices that fit your budget and follow safety rules.

When you pick materials for a building, you should know the main types of fire resistant wallboard. Each type protects in different ways and works best in certain spots. You can find choices that fit your budget and follow safety rules.

Fire Resistant Wallboard Options

Fire resistant wallboard is used in many buildings. It slows down fire and gives people more time to get out. You use it for walls, ceilings, and stairs. The most common kinds are Type X and Type C. These have special cores and extra stuff that help them fight fire.

Here is a table that shows how the main types are different:

Type | Composition | Fire Resistance | Applications | Cost |

|---|---|---|---|---|

Type X | Gypsum core with glass fibers | At least 1-hour rating | Fire barriers, stairwells, between apartments | 30% more than regular drywall |

Type C | More glass fibers, special additives | Stronger than Type X | High heat areas, easier to carry | N/A |

Fire resistant wallboard helps slow down flames. Type X gives you one hour of fire protection. Type C works better in places with more heat. Both types help you meet the flame spread rating that building codes need.

If you want to see costs, look at this table:

Wallboard Type | Cost per Sheet (4×8 ft) | Features |

|---|---|---|

Type X | $11 | Cheap, easy to buy |

Type C | $12 | Safer, saves money later |

MGO | Higher upfront cost | Lasts longer, resists water and mold, eco-friendly |

Tip: You can save money by picking the right fire resistant wallboard for each spot. Type X works well for most walls. Type C gives extra protection where it gets hotter.

Fire Rated Drywall (Type X & C)

You use fire rated wallboard like Type X and Type C in lots of buildings. These help you follow safety rules and improve flame spread ratings. Type X has a gypsum core with glass fibers. It gives at least one hour of fire protection. Type C has more glass fibers and extra stuff. It works better in hot places and is easier to carry.

Here is how you use these in different buildings:

Building Type | Type X Applications | Type C Applications |

|---|---|---|

Multi-Family Residential Buildings | Walls and ceilings between units, corridor walls, stairwell enclosures, elevator shafts | N/A |

Commercial Structures | Exit corridors, stairwells, elevator shafts, walls separating different occupancy types | N/A |

Hospitals and Healthcare Facilities | Patient room walls and ceilings, corridors and exit paths, areas housing critical equipment | N/A |

Educational Institutions | Classroom walls and ceilings, corridors and stairwells, assembly areas | N/A |

High-Rise Buildings | Elevator shafts and stairwells, mechanical rooms, floor-to-floor separations | N/A |

Fire resistant wallboard slows down fire and smoke. This helps you reach the flame spread rating needed for safe buildings. You see fire rated wallboard in stairs, halls, and rooms that need extra safety.

Magnesium Sheathing

Magnesium sheathing gives strong fire protection. You use it when you need the highest flame spread rating. This material does not burn or make toxic smoke. It lasts longer than gypsum boards and resists water and mold.

MgO boards have an A1 non-combustible rating. They can handle fire for up to four hours. Gypsum boards last up to one hour. Magnesium sheathing does not help flames spread and keeps air cleaner during a fire.

Here is a table that compares magnesium sheathing and gypsum board:

Property | MgO Board | Gypsum Board |

|---|---|---|

Fire Resistance Rating | A1 Non-Combustible (highest class) | Fire-resistant up to 1 hour |

Fire Endurance | Up to 4 hours | 30-60 minutes |

Magnesium sheathing also helps health and the environment:

Benefit | Description |

|---|---|

Non-combustible | Magnesium sheathing does not catch fire easily, making buildings safer. |

Moisture and mold resistance | Stops mold from growing, so air stays cleaner inside. |

Absence of hazardous substances | Has no harmful stuff like asbestos, formaldehyde, or silica dust. |

Recyclability | You can recycle it, so it makes less waste. |

Note: Magnesium sheathing costs more at first, but you save money later because it lasts longer and keeps your building safer.

Fire Retardant Wood Panels

You use fire retardant wood panels when you want wood’s look but need better fire safety. These panels get special treatments that slow down flames. You can add these treatments in the factory or on-site.

Here are some ways fire retardant treatments work:

Pressure-impregnation and surface application methods put chemicals into wood.

Treatments do not change how wood looks or feels.

Fire retardant finishes slow flames but do not make wood non-combustible.

Treated wood meets the flame spread rating set by the International Building Code.

Fire retardant wood panels give better fire safety. These panels have a lower flame spread rating than regular wood. Special coatings also make less smoke.

When you use fire retardant wood panels, you make buildings safer. You also keep the structure strong. Some treatments use phosphorus-based chemicals. These chemicals make a heat shield when hot. This protects the wood and slows fire.

Alert: Fire retardant wood panels are not non-combustible. You should check technical advice before using them for building support.

You can use fire resistant wallboard, magnesium sheathing, and fire retardant wood panels together. This helps you reach the flame spread rating needed for your project. You keep people safe and follow building codes.

Fire Ratings and Standards

Fire-Resistant Wall Assemblies

You need to understand how fire rated assemblies work to keep buildings safe. Fire-resistant wall assemblies use special materials and designs to slow down fire. You test these assemblies using standards like ASTM E119. This test checks how long a wall can hold back fire and keep its strength. You see results as fire resistance ratings, such as “1-hour” or “2-hour.” These ratings show how long the assembly can protect during a fire.

Here is a table that explains how fire rated assemblies perform in tests:

Aspect | Description |

|---|---|

Scope | Measures how long walls and floors contain fire and stay strong. |

Test Procedure | Exposes the assembly to high heat for a set time and checks key features. |

End Result | Rates the assembly by how long it resists fire before failing. |

You find fire-resistant wall assemblies in multi-family buildings. You use fire rated assemblies with gypsum sheathing or magnesium panels to meet fire resistance ratings. For example, a 1-hour fire rated assembly uses tested products to protect walls. A 2-hour assembly adds more layers for extra safety.

Building Code Compliance

You must follow building codes to use fire rated assemblies correctly. Codes like the International Building Code (IBC) set rules for fire resistance ratings in different building parts. You see requirements for walls, floors, and roofs. The table below shows some minimum ratings:

Fire Resistance Rating | Description |

|---|---|

1-hour | Uses tested assemblies, often with gypsum sheathing over wood. |

2-hour | Needs extra layers, tested by ASTM E119 or UL 263. |

3-hour | Adds more gypsum board for higher protection. |

You check the code for each building type. For example, Type I buildings need higher fire resistance ratings than Type V. You use fire rated assemblies to meet these rules and pass inspections.

Certification and Testing

You need certified fire rated assemblies to prove your building is safe. Groups like UL, ASTM, NFPA, and Factory Mutual test and certify fire-resistant wall assemblies. They use strict protocols to check fire resistance ratings. You see tests like UL 1709 for steel and ASTM E119 for walls. You must use assemblies that pass these tests and get certified.

Fire retardant treatments go through tough tests to meet code.

You need regular retesting and inspections by approved agencies.

Certification makes sure fire rated assemblies work as designed.

Tip: Always use certified fire rated assemblies and check for updated ratings. This helps you keep your building safe and follow the law.

Selecting the Right Sheathing

Project Needs and Location

Project Needs and Location

Think about where your project is before picking sheathing. If you build in places with wildfires, use materials that fight fire and heat. Check this table to see which choices are best:

Material Type | Fire Resistance Rating |

|---|---|

Composite shingles | Class A |

Metal | Class A |

Concrete | Class A |

Clay tiles | Class A |

Non-combustible siding | High |

Gypsum board | Nonflammable |

Pick nonflammable roofing for the most safety. Simple roofs help lower fire danger. Non-combustible siding like stucco or stone adds more protection. You can put in windows with two or three layers and use tempered glass to block heat. Metal shutters give even more safety.

Weather and climate change how sheathing works. Strong winds dry fire-protective gels faster. Low humidity makes these gels not work as well. Hot weather raises the chance of fire and can change how materials act after being outside.

Environmental Condition | Effect on Fire-Resistant Sheathing Performance |

|---|---|

High Wind (15 mph) | Dries fire-protective gels faster |

Low Relative Humidity (15%) | Makes fire-protective gels less strong |

High Temperature (23.89°C) | Raises fire risk and changes how materials work after weather |

Matching Sheathing to Codes

Make sure your sheathing follows all fire safety rules. Builders need to check if products pass tests and get certified. Here are some important standards:

Standard | Description |

|---|---|

ASTM E119 (UL 263) | Tests how long materials and assemblies resist fire. |

ASTM E84 | Measures how fast flames spread and smoke forms. |

ASTM E136 | Checks if materials can catch fire. |

UL Solutions | Tests, inspects, and certifies for safety. |

NFPA 101 | Sets rules for building safety and fire protection. |

International Fire Code | Gives safety and fire protection rules for buildings. |

Always use wood and other materials that are certified and tested. This helps you pass checks and keeps your building safe.

Cost and Performance Factors

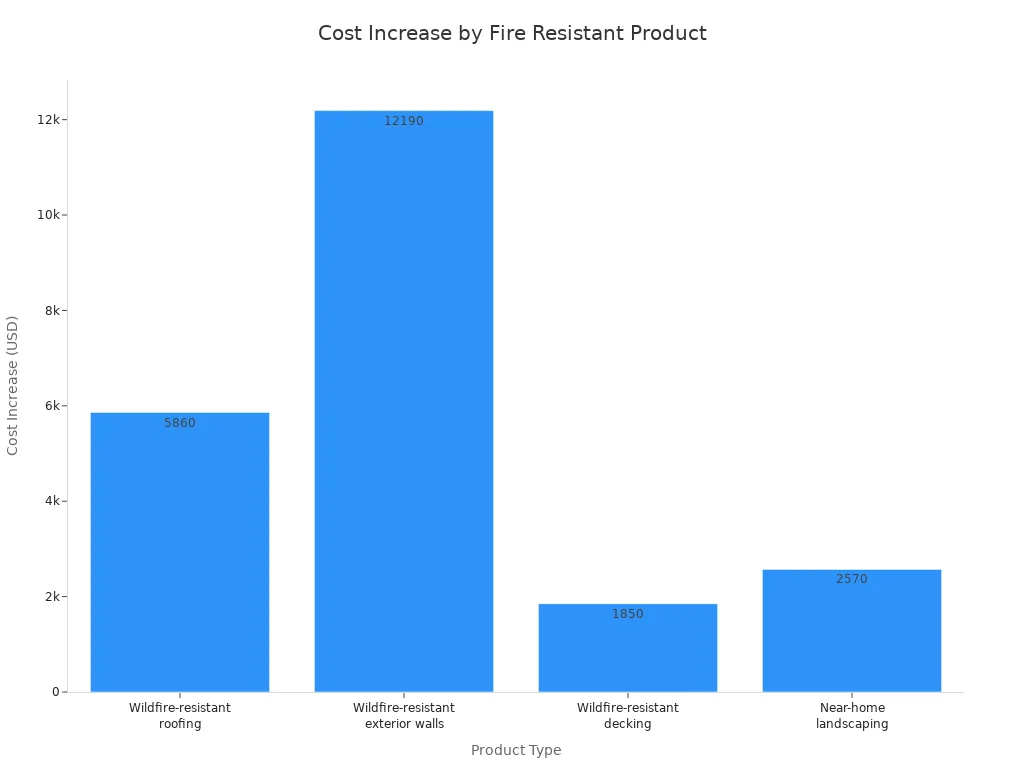

You need to think about price and how well products work when picking fire retardant wood and other sheathing. Some things cost more at first but save money later. This table shows how costs and benefits compare:

Product Type | Cost Increase | Benefits |

|---|---|---|

Wildfire-resistant roofing | $5,860 (27%) | Lasts longer, needs less fixing |

Wildfire-resistant exterior walls | $12,190 (25%) | Saves money with fiber-cement siding |

Wildfire-resistant decking | $1,850 (19%) | Lasts longer, needs less fixing |

Near-home landscaping | $2,570 (210%) | Needs less fixing with landscape fabric |

You might pay more for fire retardant wood at first, but it lasts longer and costs less to fix. Builders who use fire retardant wood often save money over time. You keep your building safe and follow safety rules.

Tip: Pick sheathing that fits your project, follows local rules, and gives the best safety for your money.

Installation Best Practices

Preparing for Installation

Get ready before you put in fire-resistant material. Check the workspace for anything unsafe. Make sure you have the right tools and safety gear. Read the instructions from the manufacturer for each material. Look at all panels and boards to see if they are damaged. If you use fire-retardant wood, check how much water is in it. The right amount of moisture helps chemicals work and keeps panels strong.

Here is a table with the best moisture levels for fire-retardant wood panels:

Type of Wood | Recommended Moisture Content |

|---|---|

Lumber | 19% or less |

Wood Structural Panels | 15% or less |

Interior Applications | Not over 28% |

If you use these numbers, fire retardant properties last longer.

Installing Fire Resistant Sheathing

Follow steps when you install fire-resistant material. First, measure and cut each panel to fit. Put panels close together so there are no gaps. Use fasteners that match the material type. Seal all seams and joints with tape or caulk that is approved. This stops fire and smoke from getting through cracks. Put fire retardant chemicals on wood as the directions say if you treat it on-site. Always check that panels are flat and not bent.

Tip: You can make fire protection better by adding more layers of fire-retardant sheathing in places with more risk.

Common Mistakes to Avoid

Builders sometimes make mistakes when installing. Try not to do these things:

Using panels with too much water. This makes fire retardant weaker.

Not sealing seams and joints. Fire and smoke can get through gaps.

Not following instructions from the manufacturer.

Putting fire retardant chemicals on unevenly or missing spots.

Using the wrong fasteners for the sheathing.

If you avoid these mistakes, fire-retardant materials work better and buildings stay safer.

Maintenance and Inspections

Routine Checks

You should check fire resistant sheathing often to keep buildings safe. Regular checks help you find problems early and save money. Follow these steps to keep your fire protection strong:

Make sure all fire stopping materials are put in the right way and meet safety rules.

Check that every hole or opening in fire-resistant barriers is sealed tight.

Look for fire dangers before you close up walls and ceilings.

Make sure your work matches fire safety codes.

Find problems early so you do not have to redo work.

Follow the manufacturer’s directions for fire stopping materials.

Check if the fire-resistance rating of installed materials fits your project needs.

Make sure fire stopping materials work well with the surfaces they cover.

Look for gaps or empty spaces in fire stopping jobs.

Check that all fire stopping materials have the right labels and certificates.

Find every spot where something goes through fire barriers and seal it with approved materials.

Look at each seal to make sure it is not broken.

Use the right fire stopping material for each type of opening.

Keep records by writing down and taking pictures of each seal.

Make sure all seals follow local building and fire codes.

🛠️ Tip: Checking often helps you keep your building safe and makes fire safety checks easier.

Repair and Replacement

You need to fix or change fire resistant sheathing when you see damage. Watch for these problems:

Soft or crumbly plywood

Mold or mildew on or behind panels

Sheathing that sags in the attic or roof

Leaks or water buildup in the roof

Damage can also look like missing fireproofing, big cracks, or spots that look worn from sunlight. These problems make fireproofing weaker and raise the risk of failure in a fire.

Sign of Damage | What It Means |

|---|---|

Surface powdering | Fireproofing may be breaking down |

Soft spots | Sheathing is losing strength |

Mold or mildew | Water is hurting the panels |

Sagging panels | Structure may not be safe |

Leaks or moisture | Water is harming fire protection |

You should follow a regular schedule for checks and fix damage fast. Clean panels when needed and use the right care steps for each material. MgO boards last longer and fight damage, but you still need to check them often. Using noncombustible siding lowers fire risks, but only if you keep it in good shape.

🔍 Note: Fast repairs and good care help fire resistant sheathing work right and keep your building safe.

You help keep buildings safe by using fire resistant sheathing. You also need to follow fire safety rules. Picking non-combustible materials protects people. Fire-rated roofing and siding make buildings safer. Checking and fixing fire barriers keeps them strong. Learn about new rules and ways to stay safe:

Put in fire-rated insulation and barriers to slow down fire.

Add firewalls to split up building spaces.

Install good ventilation and electrical systems that follow codes.

You make places safer by doing these things and learning more about fire protection.

FAQ

What is fire rated drywall?

You use fire rated drywall to slow down fire in buildings. This material has special fibers and chemicals. You install it on walls and ceilings. Fire rated drywall helps you meet safety codes and protects people during a fire.

Where do you install fire rated walls?

You install fire rated walls in places that need extra protection. These areas include stairwells, corridors, and rooms between apartments. Fire rated walls help stop fire from moving quickly. You keep people safe by using these walls.

How do you know if fire rated drywall meets safety codes?

You check the label and certification on fire rated drywall. You look for ratings like “Type X” or “Type C.” These ratings show how long the drywall can resist fire. You follow local building codes to make sure you use the right product.

Can you use fire rated drywall with other fire protection materials?

You can use fire rated drywall with magnesium sheathing and fire retardant wood panels. You combine these materials to build fire rated walls. This helps you reach the fire resistance rating your project needs.

How often should you inspect fire rated walls?

You inspect fire rated walls at least once a year. You look for damage, gaps, or missing labels. You fix problems right away. Regular checks help you keep fire rated walls strong and safe.

Project Needs and Location

Project Needs and Location