13 Nov Magnesium Oxide Wallboard vs Traditional Drywall Pros and Cons Explained

Table of Contents

- 1 Key Takeaways

- 2 Quick Pros and Cons Overview

- 3 Key Differences Between MgO Panels and Traditional Gypsum Board

- 4 Fire Resistance of Magnesium Oxide Wallboard vs Drywall

- 5 Moisture and Mold Resistance in MgO Panels

- 6 Durability of Magnesium Oxide Board and Drywall

- 7 Installation and Workability of Magnesium Wall Board

- 8 Cost Comparison: MgO Panels vs Drywall

- 9 Environmental Impact of Magnesium Oxide Wallboard

- 10 Health and Safety Aspects

- 11 Best Use Cases for Magnesium Oxide Wallboard and Drywall

- 12 FAQ

- 12.1 What makes magnesium oxide wallboard better for wet areas?

- 12.2 Can you paint or finish magnesium oxide wallboard like drywall?

- 12.3 Is magnesium oxide wallboard safe for people with allergies?

- 12.4 Does magnesium oxide wallboard cost more than drywall?

- 12.5 Can you install magnesium oxide wallboard yourself?

You want to learn about the good and bad sides of magnesium oxide wallboard and traditional drywall. If you care most about fire safety, magnesium oxide wallboard is better because it does not burn, even when it gets very hot. In wet places, it does not soak up much water, so you will not have mold problems. Drywall costs less at first, but magnesium oxide wallboard lasts longer and can save you money later. If you like green products, magnesium oxide wallboard is made from things that can be recycled. Look at the table below to see a quick side-by-side comparison:

Features | Magnesium Oxide Wallboard | Gypsum Wallboard |

|---|---|---|

Fire Resistance | Non-combustible, high heat | Slows fire, weakens |

Moisture Resistance | Absorbs 0.34% moisture | Absorbs 3% moisture |

Durability | Impact-resistant | Needs repairs |

Cost | Higher upfront, saves later | Lower initial |

Environmental | Recyclable, eco-friendly | Hard to recycle |

Key Takeaways

Magnesium oxide wallboard is very good at stopping fire. It can last up to four hours in a fire. This makes it safer for places with more risk.

Magnesium oxide wallboard works well in wet places. It does not let in water or mold. This helps it last longer in bathrooms and kitchens.

Magnesium oxide wallboard costs more at first. But it saves money later because it lasts longer and needs less fixing.

Pick magnesium oxide wallboard for green building projects. It can be recycled and makes less pollution than drywall.

Drywall is good for places that are dry and not busy. It is cheaper, but you might need to fix or replace it more often.

Quick Pros and Cons Overview

Magnesium Oxide Wallboard Summary

When you look at the key pros and cons of mgo panels, you see why many builders choose them for tough jobs. Mgo panels give you strong protection from fire, water, and mold. You can use mgo panels in places that get wet or have a lot of people moving through. These panels do not crack or dent easily, so you do not need to fix them often. Mgo panels also help keep your indoor air clean because they do not have formaldehyde or asbestos. If you want to use green building materials, magnesium oxide wallboard stands out as an environmentally friendly choice.

Tip: Mgo panels work best in bathrooms, kitchens, basements, and schools where you need extra strength and moisture resistance.

Here is a quick comparison of the benefits of magnesium oxide boards:

Pros | Cons |

|---|---|

Excellent fire and moisture resistance | Higher upfront cost |

Very durable and impact-resistant |

|

Improves indoor air quality |

|

Good for high-traffic, wet environments |

|

Environmentally friendly |

|

You get long-lasting results with mgo board, and you save money on repairs over time. The main downside is the higher price at the start.

Traditional Drywall Summary

Drywall gives you a fast and easy way to finish walls in dry rooms. You can install drywall quickly, and it costs less than mgo panels. Many people use drywall for bedrooms, living rooms, and offices. If you need to finish a project on a tight budget, drywall helps you save money right away.

But drywall does not handle water well. If you use drywall in bathrooms or basements, you may see mold or need repairs. Drywall also dents and cracks more easily than magnesium wall board. You may need to patch or replace it more often, especially in busy areas.

Here is a quick comparison of the key pros and cons of drywall:

Pros | Cons |

|---|---|

Low cost | Poor moisture resistance |

Easy to install | Needs more repairs in wet areas |

Good for dry, low-traffic rooms | Not as durable as mgo panels |

If you want a quick comparison, remember that drywall works best for simple, dry spaces. Mgo panels give you more protection and last longer in tough spots.

Key Differences Between MgO Panels and Traditional Gypsum Board

When you compare mgo panels and traditional drywall, you see clear differences in how they perform. These differences matter when you want strong, safe, and long-lasting walls. The table below gives you a quick look at the key differences between mgo panels and traditional gypsum board:

When you compare mgo panels and traditional drywall, you see clear differences in how they perform. These differences matter when you want strong, safe, and long-lasting walls. The table below gives you a quick look at the key differences between mgo panels and traditional gypsum board:

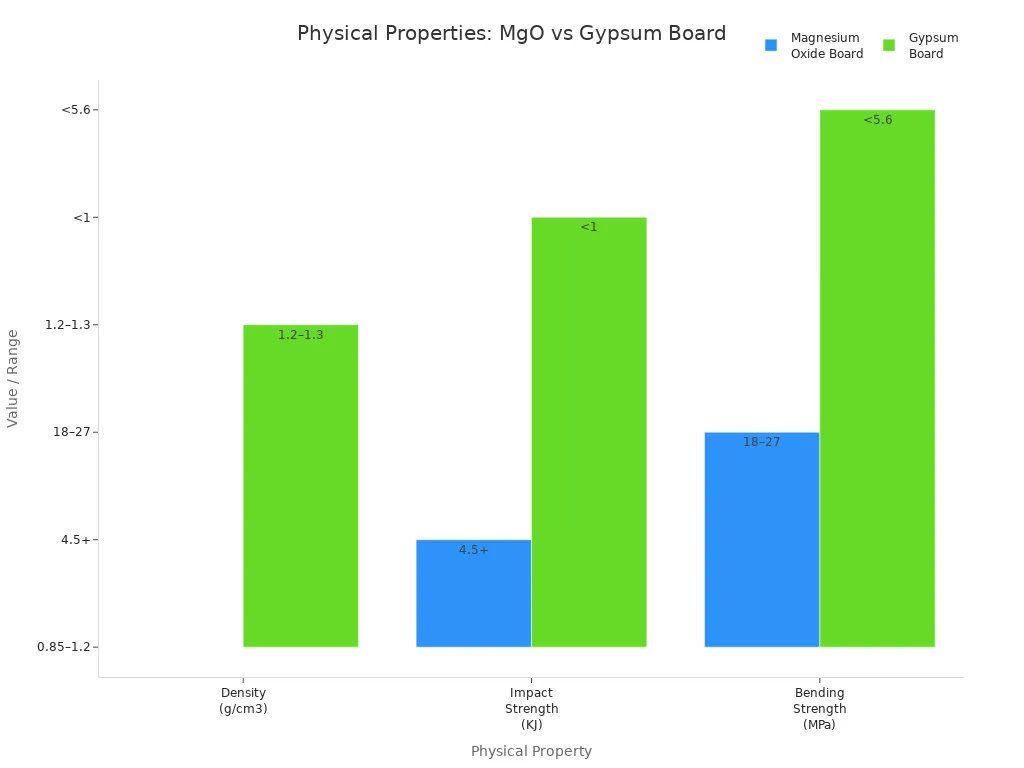

Attribute | MGO Panels | Gypsum Board (Drywall) |

|---|---|---|

Fire Resistance | Up to 4 hours, does not burn | 30–60 minutes, weakens in fire |

Moisture Resistance | Highly resistant, does not swell or mold | Absorbs water, can grow mold |

Impact Strength | More than 4.5 Kilo Joules | Less than 1 Kilo Joule |

Bending Strength | 18–27 MPa | Less than 5.6 MPa |

Density | 0.85–1.2 g/cm³ | 1.2–1.3 g/cm³ |

Eco-friendly, recyclable | Energy-intensive, hard to recycle | |

Installation | Easy, no special tools needed | May need a professional |

Note: MGO panels give you better fire and moisture protection than drywall. You also get stronger walls that last longer.

Performance Differences Explained

1. Fire Resistance

You want your walls to protect you from fire. Mgo panels can withstand fire for up to four hours. They do not burn or give off toxic smoke. Drywall slows fire for about thirty to sixty minutes, but it starts to weaken and break down when exposed to high heat. If fire safety is your top concern, mgo panels give you more time and better protection.

2. Moisture and Mold Resistance

Mgo panels stay strong in wet places. They do not swell, warp, or grow mold. You can use them in bathrooms, kitchens, or basements without worry. Drywall absorbs water quickly. When drywall gets wet, it can grow mold and lose its strength. You may need to replace drywall more often in damp areas.

3. Durability and Strength

You want walls that can handle bumps and knocks. Mgo panels have high impact strength and bending strength. They do not crack or dent easily. This makes them a good choice for schools, hospitals, or busy hallways. Drywall is softer and more likely to get damaged. You may see dents, holes, or cracks in drywall after only a short time.

4. Environmental Impact

You may care about the environment. Mgo panels use natural minerals and are recyclable. Making mgo panels uses less energy and creates less waste. Drywall comes from gypsum, a natural material, but making drywall uses more energy and creates more pollution. Drywall is also harder to recycle.

5. Installation

You can install mgo panels with regular tools. You do not need special equipment or skills. Drywall sometimes needs a professional for the best results. If you want to save time and effort, mgo panels make the job easier.

Quick Facts

Mgo panels last longer and need fewer repairs than drywall.

Magnesium oxide wallboard works well in places with high fire or moisture risk.

Mgo board gives you a strong, eco-friendly wall that stands up to daily use.

Drywall costs less at first, but you may spend more on repairs and replacements.

Magnesium wall board helps you build safer, greener spaces.

When you look at the key differences between mgo panels and traditional gypsum board, you see that mgo panels offer better fire safety, moisture resistance, and durability. Drywall works for simple, dry rooms, but mgo panels give you more protection and value in the long run.

Fire Resistance of Magnesium Oxide Wallboard vs Drywall

Magnesium Oxide Wallboard Fire Performance

You want your walls to protect you and your family during a fire. Mgo panels give you some of the best fire resistance properties you can find in building materials. Magnesium oxide wallboard does not burn, even when exposed to direct flames. In laboratory tests, mgo panels keep their strength at temperatures as high as 1200°C (about 2,192°F). You can trust that mgo panels will not break down or let fire spread quickly.

Here is a quick look at how magnesium oxide board compares to drywall in fire resistance:

Feature | Magnesium Oxide Wallboard | Drywall |

|---|---|---|

Fire Resistance Rating | A1 | A |

Non-combustibility | Yes | No |

Smoke Production | Low | High |

Harmful Gas Emission | None | Yes |

Heat Resistance | High | Moderate |

Mgo panels have passed strict ASTM fire tests. You get up to four hours of fire protection with mgo board. During a fire, magnesium wall board only releases water vapor, so you do not have to worry about breathing in harmful smoke or gases. This makes mgo panels a safer choice for homes, schools, and hospitals.

Note: Mgo panels do not lose their shape or strength in a fire. You get peace of mind knowing your walls will stand strong.

Drywall Fire Performance

Drywall gives you some fire protection, but it does not match the performance of mgo panels. Standard drywall can slow down a fire for about 30 to 60 minutes. When drywall gets very hot, it starts to weaken and fall apart. It can also produce smoke and harmful gases, which can make it harder to breathe during a fire.

You may see drywall labeled as “fire-rated,” but even these products do not last as long as mgo panels. Drywall does not have the same non-combustible core as mgo. If you want the highest level of fire resistance, mgo panels are the better choice.

If fire safety is your top concern, choose mgo panels for your next project. You get better fire resistance, less smoke, and a safer environment for everyone.

Moisture and Mold Resistance in MgO Panels

MGO Panels in Wet Environments

MGO Panels in Wet Environments

You want your walls to stay strong, even in damp rooms. Mgo panels are great at stopping water from getting in. Their dense, mineral-based structure keeps out moisture. You can use them in bathrooms, kitchens, or basements. They do not swell or warp when wet. Magnesium oxide wallboard does not soak up water, so it keeps its shape and strength in humid places.

Mgo panels also help stop mold from growing. Their inorganic makeup means mold and mildew cannot live on them. This helps keep your indoor air cleaner and safer. Tests show mgo panels keep almost all their flexural strength after many wet and dry cycles. You do not see mold, swelling, or crumbling.

Here is a quick comparison of how mgo panels and drywall work in wet places:

Property / Material | Magnesium Oxide (MgO) Board | Drywall (Gypsum Panels) |

|---|---|---|

Flexural Strength Retention | Nearly 100% after 25 cycles | Loses 36-52% |

Moisture Absorption | 0.34% | Higher |

None | Mold prone | |

Dimensional Stability | No warping or swelling | Swelling, crumbling |

Tip: Use mgo panels anywhere you expect lots of water or humidity. You get strong walls and fewer repairs.

Drywall Moisture Issues

Drywall does not do well with water. When drywall gets wet, it soaks up water and swells. Over time, the surface can crumble or break apart. Mold grows fast on wet drywall, which can make your air unhealthy.

Building codes show drywall absorbs water, which can cause damage and health problems. In wet places, drywall loses up to half its strength after getting wet many times. You may need to replace drywall more often in bathrooms, basements, or kitchens.

Magnesium wall board and mgo board do not have these problems. You get better moisture resistance and mold protection with mgo panels. If you want walls that last and keep your space healthy, pick mgo panels instead of drywall.

Durability of Magnesium Oxide Board and Drywall

MGO Panel Durability

You want your walls to last, especially in places where people move around a lot. Mgo panels give you strong, long-lasting protection. These panels stand up to bumps, knocks, and even harsh weather. You can trust mgo panels in schools, hospitals, and busy hallways. They do not crack or dent easily, so you spend less time fixing them.

Mgo panels keep their strength, even when they get wet. You do not have to worry about water damage.

Magnesium oxide wallboard resists dents and scratches better than drywall.

Mgo panels work well in high-traffic areas because they do not wear out quickly.

The core of mgo board stays strong, even if the surface gets old.

Mgo panels handle tough conditions, like high humidity and fire, without losing their shape.

Tip: If you want walls that last for years and need fewer repairs, choose mgo panels for your project.

You also get extra safety. Mgo panels have A1 non-combustible ratings. They can handle heat up to 1200°F without releasing harmful fumes. This makes them a smart choice for places where fire resistance matters.

Drywall Durability

Drywall gives you a quick way to finish walls, but it does not last as long as mgo panels. You may notice dents, cracks, or holes in drywall after only a short time, especially in busy rooms. Drywall absorbs water, so it weakens if it gets wet. Mold can grow on wet drywall, which means you might need to replace it sooner.

Drywall is softer than magnesium wall board, so it gets damaged more easily.

In high-traffic areas, drywall needs more repairs and patching.

Drywall loses its strength over time, especially if exposed to moisture.

You may spend more money fixing drywall in places like schools or basements.

Note: Drywall works best in dry, low-traffic rooms where you do not expect much wear and tear.

When you compare mgo panels and drywall, you see that mgo panels offer better durability, moisture resistance, and fire resistance. Magnesium oxide board helps you build walls that stay strong and safe, even in tough spots.

Installation and Workability of Magnesium Wall Board

Installing Magnesium Wall Board

You can install mgo panels with tools you probably already have. Many builders like that magnesium oxide wallboard does not need special equipment. You use a circular saw with a carbide blade or a utility knife to cut the boards. For scoring and snapping, a carbide-tipped scoring knife works well. When you attach mgo panels, you need corrosion-resistant screws, such as stainless steel or ceramic-coated ones. These screws keep the boards secure and prevent rust.

Here is a table that shows the main differences in installation between mgo panels and drywall:

Aspect | Magnesium Wall Board (MgO) | Drywall |

|---|---|---|

Types of Screws | Corrosion-resistant (stainless steel or ceramic-coated) | Regular drywall screws |

Cutting Methods | Circular saw with carbide blade; utility knife for scoring and snapping | Standard utility knife or saw |

Essential Tools | Circular saw, utility knife, carbide-tipped scoring knives, cordless drills | Standard saws, screw guns |

Installation Tips | Keep boards dry, use adhesives for corners, fill holes and sand | Standard installation procedures |

When you install mgo panels, you should keep the boards dry before use. You can use adhesives at the corners for extra strength. Fill any holes and sand the surface for a smooth finish. Mgo panels offer great fire resistance and moisture resistance, so you get strong walls that last.

You may face some challenges when working with mgo panels:

You must cut the boards exactly, or they will not fit well.

You need to use the correct screws to keep the boards secure.

Leave small gaps for expansion, so the boards do not crack with weather changes.

Make sure the boards stay even after installation.

Quality can differ by brand, so check before you start.

Tip: Take your time with each step. Careful work gives you the best results with mgo panels.

Installing Drywall

You will find drywall easy to install if you have done basic home projects before. You cut drywall with a standard utility knife or saw. Regular drywall screws work well for attaching the panels. Most people use screw guns or drills to speed up the process.

Drywall installation follows a simple process. You measure, cut, and attach the panels to the wall studs. After that, you tape the seams, apply joint compound, and sand the surface. Drywall works best in dry rooms where you do not need extra fire resistance or moisture resistance.

If you want a quick and budget-friendly wall, drywall is a good choice. You can finish most rooms in a short time. Just remember, drywall does not offer the same strength as mgo board, so you may need more repairs in busy or wet areas.

Cost Comparison: MgO Panels vs Drywall

Material and Labor Costs

Material and Labor Costs

When you look at the price for mgo panels and drywall, you see some important differences. The cost comparison starts with the price per square foot. You usually pay between $1.50 and $3.50 per square foot to install drywall, which includes both materials and labor. Magnesium oxide wallboard falls in a similar range for installation, but the price for mgo panels themselves often averages between $1.50 and $2.50 per square foot. Drywall panels can cost less, with prices from $0.40 to $1.20 per square foot for the material alone.

Here is a quick list to help you compare:

Mgo panels: $1.50–$2.50 per square foot (material)

Drywall: $0.40–$1.20 per square foot (material)

Installation for both: $1.50–$3.50 per square foot (material and labor)

You might notice that the price for mgo panels is higher at first. Drywall gives you a lower upfront price, which can help if you have a tight budget. If you want to save money right away, drywall may look like the better choice.

Long-Term Value

The cost comparison changes when you think about long-term value. Mgo panels give you strong fire resistance, moisture protection, and durability. You do not need to repair or replace mgo panels as often as drywall. Mgo panels resist water, mold, and fire, so you spend less on maintenance over the years. Gypsum drywall often needs repairs in humid rooms, which can raise your total price over time.

You get more value from mgo panels because they last longer and need fewer repairs. Magnesium wall board stands up to tough conditions, so you do not have to worry about extra costs. Investing in mgo board may save you money in the long run, even if the initial price is higher.

Tip: If you want walls that last and keep costs low over time, mgo panels offer a smart choice for your project.

Environmental Impact of Magnesium Oxide Wallboard

Sustainability of Magnesium Oxide Board

You might want to pick materials that are good for the earth. Mgo panels are known for being eco-friendly. Using mgo panels helps lower your carbon footprint. Making magnesium oxide wallboard creates much less CO2 than drywall. Look at this table:

Material | |

|---|---|

Magnesium Oxide Board | 340 |

Traditional Gypsum Board | 740 |

Mgo panels give off less than half the carbon emissions of drywall. They use safe, natural materials and do not have harmful chemicals or VOCs. This helps keep your indoor air cleaner. You can recycle mgo panels when you are done with them, so less waste goes to landfills.

Mgo panels work with green building certifications like LEED.

They resist fire and moisture, so buildings last longer.

Mgo panels use less energy to make, which is called low embodied energy.

Choosing mgo panels helps the environment on your project.

More builders are using mgo panels in green building projects now. Demand for mgo panels has gone up by 35% in LEED-certified buildings. Governments are also investing in public buildings that use these boards.

Drywall Environmental Considerations

Drywall is still popular, but it is not as good for the environment. Making drywall uses more energy and makes more carbon emissions. Most drywall goes to landfills after use because it is hard to recycle. Here is a quick comparison:

Feature | Magnesium Oxide Wallboard | Drywall |

|---|---|---|

Recyclability | High | Low |

End-of-life Disposal Options | Typically landfilled | |

Environmental Impact | Higher carbon footprint |

Drywall soaks up water and can get moldy, so you might need to replace it more often. This means more waste in landfills. Drywall does not help you get as many green building points as mgo panels. If you want to build in a way that helps the planet, magnesium wall board and mgo board are better choices.

Tip: Pick mgo panels if you want less waste, lower emissions, and to meet green building goals.

Health and Safety Aspects

Magnesium Oxide Wallboard Health Factors

You want your house to be safe and healthy. Magnesium oxide wallboard helps you reach this goal. This material does not have dangerous chemicals or heavy metals. You do not need to worry about breathing in bad fumes. The boards only let out tiny magnesium ions, which are safe for people and pets. People with allergies or asthma can feel okay because the panels do not give off VOCs, formaldehyde, or asbestos.

You also get cleaner air inside. Unlike many other building materials, magnesium oxide wallboard does not fill your home with chemical smells. You notice the fresh air right away. The air stays clean, and you avoid problems from long-term chemical leaks.

No VOCs, formaldehyde, or asbestos

Safe for people with allergies or asthma

No harmful chemical smells

Helps keep indoor air clean

You should know about some safety issues. Magnesium oxide panels soak up more water than cement boards. If the panels get too wet, salts can move to the surface and cause “weeping.” This can hurt the wall and things nearby. Some lower-quality boards may have leftover magnesium chloride, which can rust metal parts and cause safety problems.

Panels soak up more water than cement boards.

Too much water can cause “weeping” and surface damage.

Leftover magnesium chloride may rust metal parts.

Tip: Pick good quality panels and keep them dry when you put them in to stop these problems.

Drywall Health Factors

You might use drywall in many rooms. Drywall is common, but it can affect your health. Some drywall has chemicals that let out VOCs and formaldehyde. These things can make the air in your house worse and may cause breathing problems over time. Drywall does not protect you from allergens as well as magnesium oxide wallboard.

Regular drywall can keep letting out chemicals for years. You might not notice at first, but the air in your house can get less healthy. If you want the safest choice for your family, think about how each material changes your indoor air.

May have VOCs and formaldehyde

Can make indoor air worse

Not the best for people with allergies or asthma

Note: If you want cleaner air and fewer health risks, magnesium oxide wallboard is a safer choice.

Best Use Cases for Magnesium Oxide Wallboard and Drywall

Where to Use Magnesium Oxide Wallboard

Where to Use Magnesium Oxide Wallboard

You want strong walls that last in tough places. Magnesium oxide wallboard works well in areas where you need extra protection from fire, water, or mold. You can use it in places that get wet, like bathrooms or basements. It also fits well in schools, hospitals, and kitchens because it does not crack or dent easily. If you need walls that help keep out noise or keep rooms warm, this board gives you good insulation and soundproofing.

Here is a table to help you see the best use cases for mgo panels:

Use Case | Why It Works Well |

|---|---|

Construction | Strong, light, resists water, mold, and pests |

Insulation | Keeps heat in, blocks noise |

Fireproofing | Stays strong in high heat, stops flames, does not give off toxic smoke |

Industrial Applications | Durable, easy to clean, safe for wet or messy areas |

Tip: Choose magnesium oxide wallboard for places that need to stay dry, safe, and strong. You get peace of mind in busy or risky spaces.

Where to Use Drywall

You want a fast and affordable way to finish walls in dry rooms. Drywall gives you a smooth surface for painting or decorating. It works best in bedrooms, living rooms, and offices where you do not expect much moisture or heavy use. You can cut drywall to fit any space, so it is easy to use for many projects. If you want to change the look of your room later, you can repaint drywall without much trouble.

Check this table to see where drywall fits best:

Characteristic | Why It’s a Good Choice |

|---|---|

Cost-effective | Saves money on materials and labor |

Quick installation | Goes up fast, so you finish your project sooner |

Easy customization | Cuts to fit any room shape or size |

Repaintable | Lets you update your walls without replacing them |

Note: Drywall is a smart pick for dry, low-traffic rooms where you want to save time and money.

You need walls that fit what you want. Magnesium oxide wallboard is great for stopping fires, blocking water, and staying strong. Drywall is cheaper at first, but it breaks and needs fixing more often. Experts say to use magnesium oxide wallboard in places with fire danger, lots of water, or many people. Check this table to help you pick:

Best For | Magnesium Oxide Wallboard | Drywall |

|---|---|---|

Fire Safety | ✅ | ❌ |

Moisture Resistance | ✅ | ❌ |

Durability | ✅ | ❌ |

Budget Projects | ❌ | ✅ |

Think about what could go wrong and what you want before you decide.

FAQ

What makes magnesium oxide wallboard better for wet areas?

Magnesium oxide wallboard keeps out water very well. It does not get bigger or let mold grow when it gets wet. You can put it in bathrooms, kitchens, or basements. You do not have to worry about water hurting the walls.

Can you paint or finish magnesium oxide wallboard like drywall?

You can paint or finish magnesium oxide wallboard. Start with a primer to help the paint stick. You can also put tiles or wallpaper on it. The surface takes paint well and looks nice when you are done.

Is magnesium oxide wallboard safe for people with allergies?

Magnesium oxide wallboard does not let out VOCs, formaldehyde, or asbestos. This helps keep the air inside cleaner. People with allergies or asthma often feel better in rooms with this wallboard.

Does magnesium oxide wallboard cost more than drywall?

You pay more at first for magnesium oxide wallboard. But you save money later because it lasts longer and does not need many repairs. Drywall costs less at the start but may need more fixing over time.

Can you install magnesium oxide wallboard yourself?

You can put up magnesium oxide wallboard with simple tools.

Use screws that do not rust.

Cut the panels with a knife or saw.

Follow the maker’s steps to get the best results.

MGO Panels in Wet Environments

MGO Panels in Wet Environments Material and Labor Costs

Material and Labor Costs Where to Use Magnesium Oxide Wallboard

Where to Use Magnesium Oxide Wallboard