08 Sep Application Of Magnesium Oxide Board In Steel Structure Buildings

Table of Contents

Magnesium oxide board is very important in steel structure buildings. It gives strong fire resistance, helps support the building, and saves energy. Many builders pick MgO boards because they do not burn, resist water, and are good for the environment.

MgO boards stop fires well, follow safety rules, and help buildings stay safe during disasters.

The boards are light but strong. They help hold up the building and stop mold, mildew, and heat.

MgO boards help make buildings greener. They are good for the planet and make less pollution.

Prefabricated MgO panels are made with digital tools. They help build faster and make less trash, which is better for the environment.

City buildings use MgO boards because they fight fire, water, and tough weather. This makes them a smart and safe choice for new buildings.

Key Takeaways

MgO boards stop fire, water, and mold. This keeps steel buildings safe and healthy. These boards are light and strong. They are easy to put in. Builders save time and make less waste when building. MgO boards help keep heat or cool air inside. This lowers the cost to heat or cool the building. Pick the right MgO board and keep it dry. This stops water damage and rust on steel. MgO boards cost more at first. But they last long and keep people safe. They also save money on fixes and energy later.

Applications

Magnesium oxide board is used a lot in steel buildings. MgO boards are found in walls, ceilings, roofs, floors, and SIPs. Builders use them inside and outside because they are strong and safe. MgO boards stop fires, keep heat in, and last a long time. The next parts show how MgO boards help in steel buildings.

Wall Systems

Steel building walls often have MgO boards inside. These boards help stop fires and keep people safe. MgO boards do not burn or make bad gases. They are safer than gypsum plasterboard. MgO boards make walls stronger and last longer. They can take hits, squeeze, and get wet without breaking.

Note: MgO boards are light and simple to put in. They do not grow mold or bacteria, so air inside stays clean.

MgO boards are used for wall dividers, inside walls, and outside covers. Builders in North America and other places use thin MgO boards for these jobs. More people want safe and green building materials, especially for homes.

Ceilings and Roofs

MgO boards are good for ceilings and roofs in steel buildings. They have a top fire rating and do not let flames spread. MgO boards can stop fire for one to four hours. They follow strict safety rules like EN 13501-1 and ISO 834-1-1999.

MgO boards keep out water and do not crack in hot or cold weather. They do not grow mold or mildew. Builders use them outside and on roofs because they are tough. MgO boards also stand up to wind and do not bring bugs.

MgO boards are easy to put in, like drywall.

They help the planet by making less pollution when made.

Flooring

MgO boards are also used for floors. They are strong but not heavy. Floors with MgO boards can hold a lot of weight. They do not break or bend easily. MgO boards work well in busy places like halls and stores. They do not soak up water, so they do not swell or rot.

MgO boards stop mold and fungus from growing. This makes them good for wet places. They are tougher than many old flooring materials. MgO boards are not the main support but make a strong base for other floors.

Tip: MgO raised floors have steel shells and MgO boards. This makes floors extra strong for big buildings that need to hold heavy things.

SIPs and Sheathing

MgO boards are used in SIPs and sheathing for steel buildings. MgO SIPs are great at stopping fire and stay strong up to 1200°F. They do not burn, rot, or make bad chemicals. This makes them safer than drywall or plywood.

MgO SIPs keep heat in better than old SIPs. This saves energy and lowers bills. MgO boards do not grow mold or mildew, so buildings stay healthy. MgO SIPs and sheathing are tough and last longer than many other materials.

MgO SIPs are made ahead of time, so building goes faster and makes less trash.

MgO boards in SIPs and sheathing follow fire safety rules, so they are good for apartments and stores.

These panels help the planet by using less energy and can be recycled.

MgO boards in SIPs and sheathing help builders make steel buildings that are safer, stronger, and save energy.

Benefits of Magnesium Oxide Board

Fire and Weather Resistance

Fire and Weather Resistance

MgO boards help steel buildings stay safe from fire. These boards do not burn or make smoke. They also do not make harmful gases. Labs like ICC-ES test MgO boards for fire and weather. They check how the boards handle freezing, water, and rust. The tests show MgO boards stay strong in hard conditions.

MgO boards meet strict safety rules like AS 1530.1.1994. They also follow ASNZS 1530.3.1999. These tests show MgO boards do not catch fire. They are safe for people and the planet. The boards have low chloride and no asbestos. They also have very few bad chemicals.

MgO boards can stand very high heat. The binder inside changes to magnesium oxide when it gets hot. Magnesium oxide melts at about 2800°C. The board lets out water when heated. This helps stop fire from spreading. MgO boards resist fire better than most other materials.

Criteria | MgO Board | Gypsum Board | Cement Board |

|---|---|---|---|

Fire Resistance Rating | Non-combustible, up to 4 hrs | Limited, often <1 hour, needs multiple layers or treatment | Highly fire-resistant, better than gypsum but less than MgO |

Thermal Combustibility | Non-combustible | Combustible | Non-combustible |

Flame Spread | Zero flame spread | Moderate flame spread | Low flame spread |

Fire Endurance | Very high | Limited | High |

MgO boards last up to four hours in fire tests. Gypsum boards last less than one hour. Cement boards do well, but MgO boards are best for fire. MgO boards do not lose strength at 800°C. They do not catch fire until 1200°C.

MgO boards also stand up to tough weather. They do not crack in hot or cold places. Studies show MgO boards with magnesium oxysulfate resist water and rust. These boards stay strong after lots of humidity and heat changes. They work well in many climates.

Note: MgO boards do not swell, rot, or grow mold. This keeps buildings safe and healthy.

Acoustic and Thermal Performance

MgO boards help block noise in steel buildings. Rooms stay quieter with these boards. This is good for schools, offices, and homes. MgO boards also keep heat inside in winter. They keep heat out in summer. This saves money on heating and cooling.

Builders use MgO boards to insulate walls and roofs. The boards help stop heat loss and gain. Adding MgO boards to old buildings can save up to 30% on energy bills. MgO boards help buildings meet green rules and support the planet.

MgO boards insulate walls, floors, and roofs well.

The boards help keep rooms at a steady temperature.

MgO boards are eco-friendly and help get green building awards.

MgO boards resist water, so insulation works longer. The boards do not break down when wet. They keep their sound and heat-blocking power for years.

Durability and Strength

MgO boards are tough and strong for steel buildings. They resist hits better than gypsum boards. They do not break, bend, or swell when wet. This means MgO boards last longer and need fewer repairs.

MgO boards keep their shape and strength in fires.

The boards resist mold, bugs, and rot.

MgO boards stay strong in wet or old buildings.

MagPanel MgO boards have a top fire rating and high strength. These features help buildings last and stay safe. The boards are light, so workers can install them easily. This means less damage and less waste during building.

Tip: Using MgO boards helps builders make strong, safe, and green buildings that last many years.

MgO boards are made from natural materials. They can be recycled and break down safely. Making MgO boards uses less energy and makes less pollution than cement or gypsum boards. MgO boards can be recycled or break down in nature. This helps keep the planet clean and reduces trash.

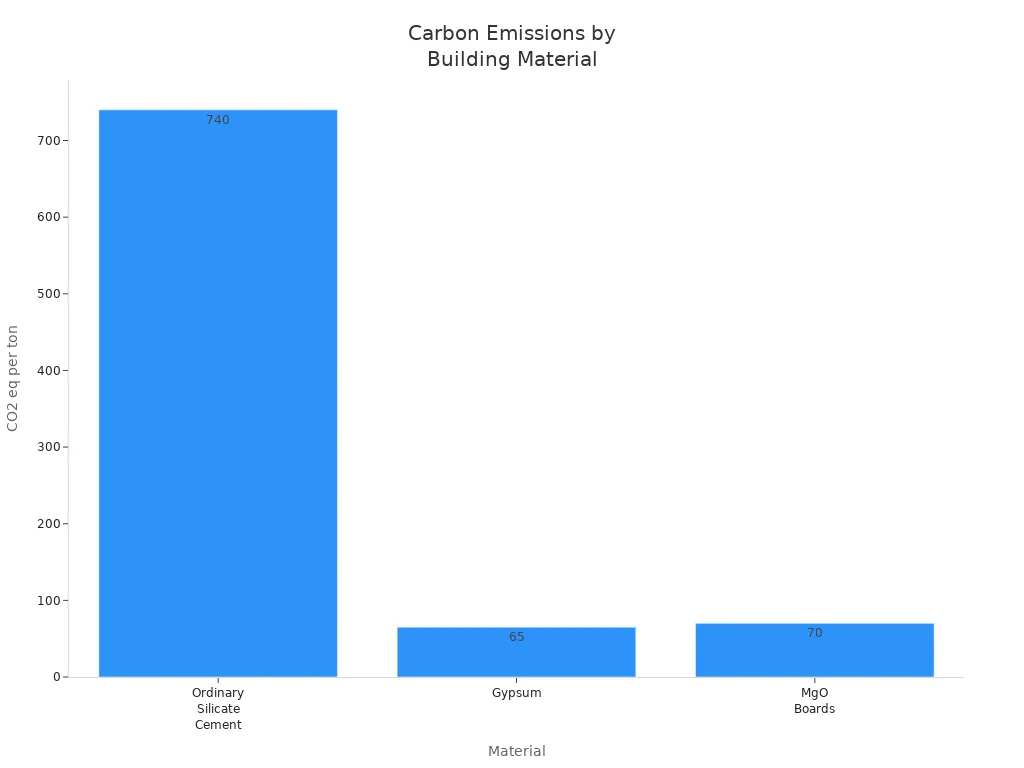

Material | Carbon Emission Factor (kg CO2 eq per ton) |

|---|---|

Ordinary Silicate Cement | 740 |

Gypsum | 65 |

MgO Boards | 70 |

MgO boards make less carbon than cement. They are easier to recycle than gypsum. The boards resist mold, mildew, and rot. This helps keep indoor air clean. Builders pick MgO boards because they are strong, last long, and help the planet.

Installation in Steel Construction

Preparation and Framing

Getting ready is important for a strong job with mgo boards. Workers need to keep mgo boards in a cool, dry place with good air. The boards should be stacked flat so they do not bend or crack. Before putting them up, let the boards get used to the room’s air and temperature. This helps stop the boards from moving later.

Frames can be made of metal or wood. The frame must be strong enough for mgo boards. Light steel frames work well with these boards. Workers should keep the frame clean and dry. They must wear safety gear and use the right tools to cut mgo boards. Leave small gaps and use special joint paste so the boards can handle changes in heat or wetness.

Tip: Always make sure the frame is flat and strong before putting on mgo boards. This stops problems from happening later.

Fixing Methods

To attach mgo boards to steel frames, use the right screws. For metal frames, self-tapping screws are best. For wood, use drywall screws or gun nails. Screws and nails should not rust so the boards last longer. Put screws or nails 200–300 mm apart to hold the boards tight.

Put fiberglass tape and joint paste between the boards. In wet or fire-risk places, use special sealants or fire-safe paste. Make sure the boards are clean and dry before finishing. This helps the boards and insulation last longer.

Finishing Steps

Finishing mgo boards has a few steps to protect them and make them look nice:

Put fiberglass tape on all seams, then cover with joint paste. Let it dry all the way.

Sand the dry paste with 240 grit sandpaper to make it smooth. Wipe off dust before the next step.

Use a primer that blocks water, like epoxy resin or polyurethane, to seal the boards.

Paint with good acrylic or latex paint so the boards last and stay dry.

In wet places, add a clear sealer to stop water and stains.

Check the finished boards for cracks, bends, or holes.

To keep them nice, clean gently and fix any damage fast.

Mgo boards are easy to use because they are light and fit steel frames well. These boards help keep heat in, so buildings save energy. Doing each step right makes sure the boards work well for a long time.

Challenges in Building Applications

Moisture and Cracking

Moisture can make problems for mgo boards in steel buildings. When the air is very wet, water can sit on mgo boards. This water can cause mold, stains, and cracks. Some mgo boards, like ones with magnesium chloride, soak up water fast. This makes the board weak and can cause it to bend or break apart. In Denmark and Canada, builders saw mgo boards drip water. This is called “sweating” or “crying.” Water dripping can hurt walls and make boards less strong.

Common moisture problems:

Boards soak up water from wet air

Mold and mildew can grow

Boards can crack or bend

Plaster can break off

Fasteners can rust

Not all mgo boards handle water the same way. The kind and quality of the board matter a lot. Boards with magnesium oxysulfate do better with water. Builders should pick boards that resist water and use good building steps. They need to keep boards dry, use the right sealants, and leave small gaps for movement. Checking boards often helps find problems early.

Tip: Always keep mgo boards dry before and after putting them in. This helps them stay strong and last longer.

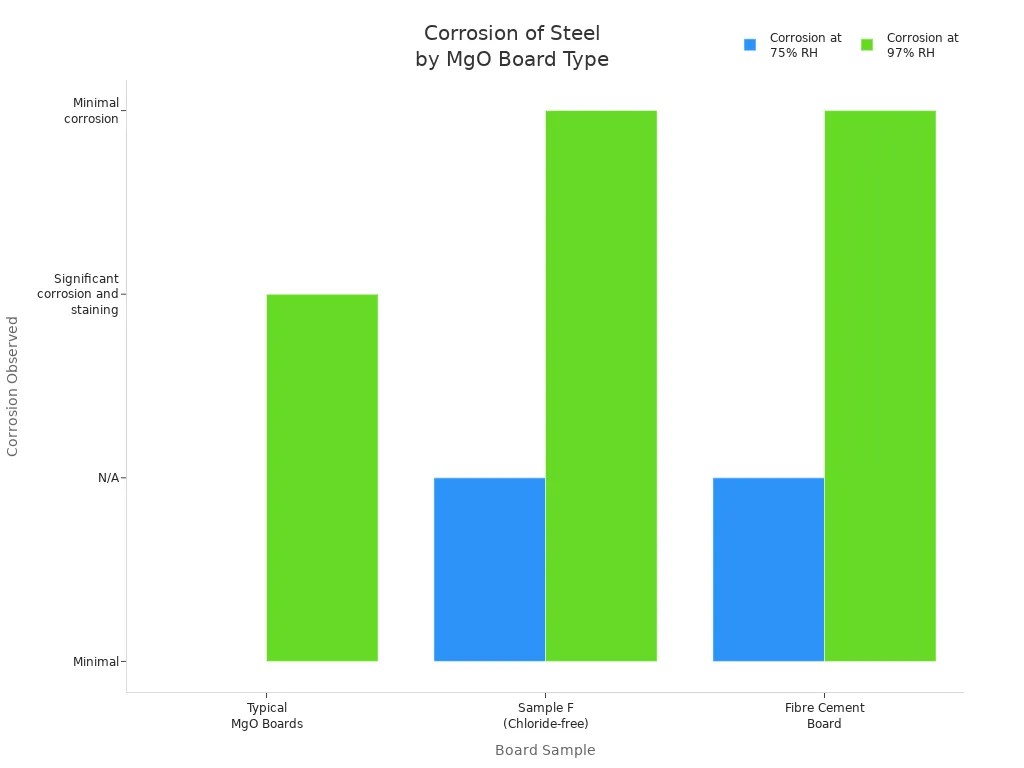

Corrosion Risks

Corrosion is a big problem when using mgo boards with steel. Many mgo boards have magnesium chloride. This can make steel fasteners rust, especially in wet places. When the air is very humid, chloride can move from the board to the steel. This makes rust happen faster. Rust makes steel weak and can hurt the building.

Board Sample | MgCl2 Content | Humidity Level | Corrosion Seen | Water Absorption |

|---|---|---|---|---|

Typical mgo boards | 97% RH | Lots of rust | High | |

Chloride-free boards | ~0% | 97% RH | Little rust | Low |

Fiber cement board | N/A | 97% RH | Little rust | Low |

Using magnesium sulfate instead of magnesium chloride in mgo boards helps stop steel from rusting. Builders should use stainless steel or coated fasteners. They should also keep boards away from water to help them last longer.

Cost Considerations

Mgo boards cost more at first than drywall. They are made in a special way and need skilled workers. But mgo boards are stronger, resist fire, and handle water better. These things save money later because you fix and replace them less.

Aspect | mgo boards | Drywall |

|---|---|---|

First Cost | Higher | Lower |

Strength | Strong, lasts long | Breaks easier |

Resistance | Fire, water, mold, impact | Not as strong |

Repairs Needed | Not often | Needs more repairs |

Money Saved Over Time | Costs more later |

Some builders pay more because of tariffs and not enough skilled workers. In some places, rules and insurance make it hard to use mgo boards because of water and rust risks. Still, many builders pick mgo boards for their strength, resistance, and energy savings in steel buildings.

Case Studies

Commercial Projects

Commercial Projects

Many big buildings use MgO boards with steel frames. Office towers, hospitals, and schools stay safer from fire because of these boards. MgO boards also help the air inside stay clean. Builders like that MgO boards are light and good for the earth. Factories and hospitals use them to stop fires from spreading. If workers put them in right and keep them dry, MgO boards work well in these places. Sometimes, it is hard to use MgO boards for all designs. But talking to suppliers helps builders find good ways to use them.

Residential Buildings

MgO boards work well in homes with steel frames. MagPanel MgO boards do not let fire spread, so they are good for fire-safe walls and ceilings. These boards do not soak up water or grow mold, so homes stay safe in wet places. Builders say MgO boards stay strong and do not bend or rot. The sulfate in the boards keeps steel frames from rusting, which is important for houses. Putting in MgO boards is easy, like drywall, so workers use them for many parts of the house. People living in apartments see that their homes are stronger and safer from fire. Many builders finish jobs faster and spend less money. MgO boards also help save energy and make buildings greener.

MgO boards are stronger than gypsum drywall and plywood.

They are safe, can be recycled, and do not fill up landfills.

Builders and designers use MgO boards with normal steel frames.

Lessons Learned

Case studies teach us important things about using MgO boards in steel buildings:

MgO boards are great for stopping fires and helping the environment in many types of buildings.

Keeping boards dry is very important. Boards with magnesium chloride can soak up water and hurt steel. Boards with magnesium oxysulphate do not have this problem.

Workers need to know how to install and seal the boards the right way.

MgO boards cost more at first, but they save money later because they last longer and stop fires.

The best way is to pick the right MgO board, seal the edges, and follow the maker’s rules.

Tip: Builders should always keep MgO boards dry and use skilled workers to get the best results in steel buildings.

Magnesium oxide board helps steel buildings stay safe from fire. It is tough and lasts a long time. It also helps save energy in buildings. Reviews say mgo boards stay strong in heat and stop flames. They help keep people safe. Mgo boards are used in homes and big buildings. Builders put mgo boards on walls, floors, and ceilings. The boards are light and easy to put in. They are good for the planet. More rules now ask for fire-safe building materials.

Experts think mgo boards will be used even more in steel buildings. This will happen as cities get bigger and green rules get stronger.

Mgo boards will help make buildings safer, smarter, and better for the earth in the future.

FAQ

What makes mgo boards different from regular drywall?

Mgo boards resist fire, water, and mold. Drywall does not stop fire as well. Mgo boards last longer and work better in steel buildings. Builders use mgo boards for safety and strength.

Can mgo boards be used outside in steel buildings?

Mgo boards work well outside. They stand up to rain, wind, and sun. Mgo boards do not rot or crack. Builders use mgo boards for walls, roofs, and floors in many climates.

How do mgo boards help with fire safety?

Mgo boards do not burn. They stop flames from spreading. Mgo boards protect steel buildings for up to four hours in fire tests. Many safety rules ask for mgo boards in new buildings.

Are mgo boards safe for people and the environment?

Mgo boards do not have asbestos or harmful chemicals. They help keep indoor air clean. Mgo boards use less energy to make. Builders pick mgo boards to help the planet and keep people safe.

What should builders know before installing mgo boards?

Builders must keep mgo boards dry before use. They need to use the right screws and sealants. Mgo boards fit steel frames well. Workers should follow the maker’s steps for best results.

Fire and Weather Resistance

Fire and Weather Resistance Commercial Projects

Commercial Projects