07 Aug Everything You Need to Know About Lightweight Cement Board in 2025

Table of Contents

- 1 Key Takeaways

- 2 Lightweight Cement Board Overview

- 3 Features and Benefits

- 4 Lightweight Cement Panels & Applications

- 5 Comparing Lightweight Cement Board and Alternatives

- 6 FAQ

- 6.1 What is the main difference between lightweight cement board and lightweight mgo board?

- 6.2 Can you use lightweight mgo board in wet areas like bathrooms?

- 6.3 Is lightweight mgo board safe for the environment?

- 6.4 How do you install lightweight mgo board?

- 6.5 Does lightweight mgo board cost more than other boards?

Lightweight cement board is a durable building material that offers strength without the heavy weight of traditional cement boards. This lightweight cement board is made from a combination of cement, mineral aggregates, and fibers, providing a tough and reliable panel. Using lightweight cement board reduces the effort needed for installation and makes handling much easier. Additionally, this lightweight cement board is resistant to water and mold, making it an excellent option for new construction projects in 2025.

Key Takeaways

Lightweight cement board is strong and tough. It is much lighter than regular cement boards. This makes it easier to move and put in place.

This board does not let water or mold in. It is great for wet places like bathrooms and kitchens.

You can use it for many things. It works for walls, floors, and ceilings. It is good for tile bases too. You can use it inside or outside.

Lightweight cement board costs less at first than other choices. But it might need sealing in very wet spots.

If you follow the right steps to install it, it will last longer. Using waterproof layers helps keep the board strong.

Lightweight Cement Board Overview

What Is It

Lightweight cement board is a new material for building. It helps make building jobs faster and easier. This board is made mostly from Portland cement, fine silica sand, and fibers like wood chips or cellulose. Factories use special machines to press and dry the boards with steam and heat. This makes the board strong and able to handle water. The board is much lighter than regular concrete. It weighs about one-third as much as normal concrete. Even though it is lighter, it is still very strong and safe. You can use lightweight cement board for walls, ceilings, floors, and even furniture. Because it is light, you can carry and install it easily. This saves time and money when building.

Composition

When you look at what is inside lightweight cement board, you see a mix of different things. The main parts are:

Hydraulic cement powders, like Portland cement or high alumina cement (about 65-75%)

Water (20-35%)

Surfactants, which help make foam (0.05-1%)

Polyvinyl alcohol, which keeps the foam stable (0.1-1%)

Retarders like citric acid (up to 0.5%)

Superplasticizers (0.15-1%)

Sometimes lightweight fillers, like coated perlite

Calcium sulfate (land plaster) for extra strength

Reinforcement mesh, often made from fiberglass or basalt fiber

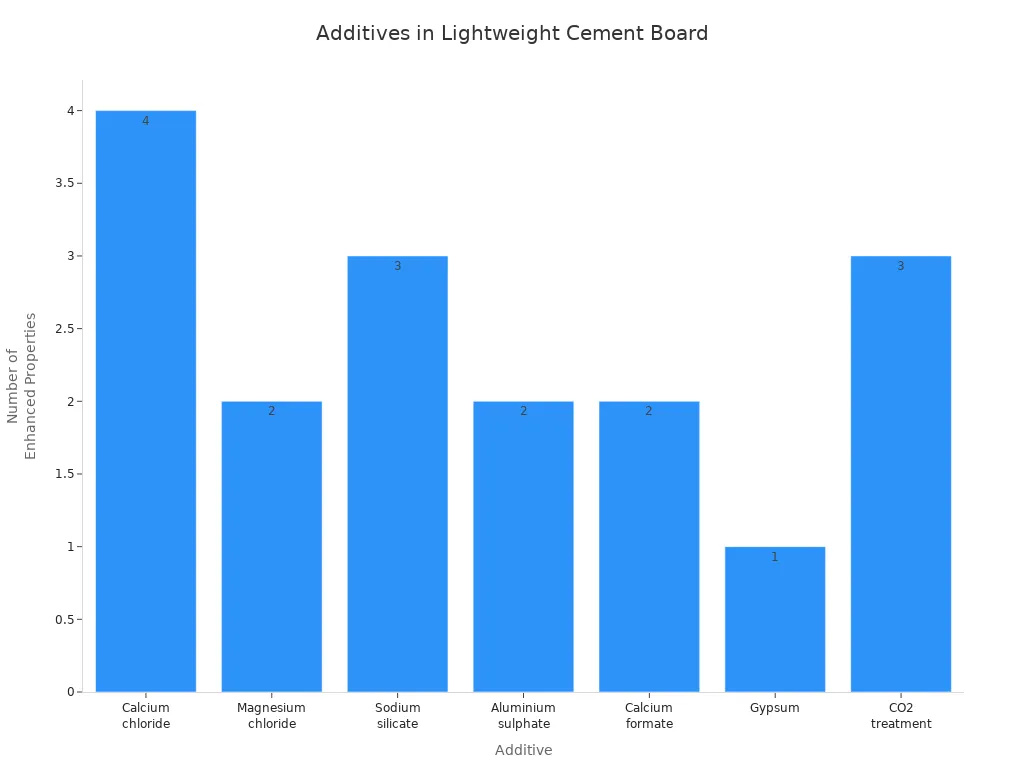

All these parts work together to make the board lighter but still strong. The foam is made first and then mixed in. This helps the board stay strong and not break. Factories also add special chemicals to make the board work better. Here is a table that shows some common additives and what they do:

Additive | Purpose / Effect |

|---|---|

Calcium chloride (CaCl2) | Makes cement set faster, makes it stronger, and helps stop water from getting in |

Magnesium chloride (MgCl2) | Helps the board set quickly and makes it stronger at first |

Sodium silicate | Helps the board stick together and makes it stronger |

Aluminium sulphate | Makes the board more waterproof and stops water from soaking in |

Calcium formate | Makes the board set faster and stronger at the start |

Gypsum | Makes the board stronger when used in small amounts |

Carbon dioxide treatment | Helps the board dry faster, get stronger, and stay stable |

Key Properties

Lightweight cement board has some special features that make it useful. It is not as heavy as other boards, so you can move and install it easily. Some ISO boards are up to 80% lighter than regular cement boards of the same size. Even though it is lighter, it is still very strong. It can hold heavy things and does not bend or break easily.

Factories sometimes add graphene oxide to make the board even stronger. Just a little bit of graphene oxide can make the board over 30% stronger and almost 60% better at not bending. The board is also made to resist water and mold. You can use it in kitchens, bathrooms, and outside without worrying. The special chemicals and mesh help keep the board strong, even if it gets wet or humid.

Tip: If you want a building material that is easy to put in, strong, and safe for wet places, lightweight cement board is a good pick.

You can use lightweight cement board inside or outside. It is light, strong, and does not get damaged by water or mold. That is why many people like to use it for building in 2025.

Features and Benefits

Durability

When you choose lightweight cement board, you get a product known for its strength and durability. You can use it in many places, even where the weather changes a lot. Tests show that some boards with recycled fibers lose strength if they get wet for a long time. For example:

Boards with 50% recycled cellulose fibers lost up to 50% of their strength after soaking in water for 96 hours.

Boards with less recycled fiber did better, but still lost some strength.

Boards with too much recycled fiber showed damage like warping and peeling paint.

Experts suggest using less than 10% recycled fiber for outdoor use to keep the board strong.

PermaBase cement boards have passed tough tests. They resist rot, swelling, and breaking down, even in wet weather. You can trust these boards to last for years. They come with a 15-year warranty for outside use, showing their reliable strength and durability.

Water and Mold Resistance

Lightweight cement board stands out for its water and mold resistance. The board does not soak up water like drywall or wood. This means you can use it in bathrooms, kitchens, and other wet places without worry. The table below shows how it compares to drywall:

Criteria | Cement Board | Drywall |

|---|---|---|

Moisture Resistance | Water-resistant but not waterproof | |

Mold Resistance | Less mold-resistant; can grow mold |

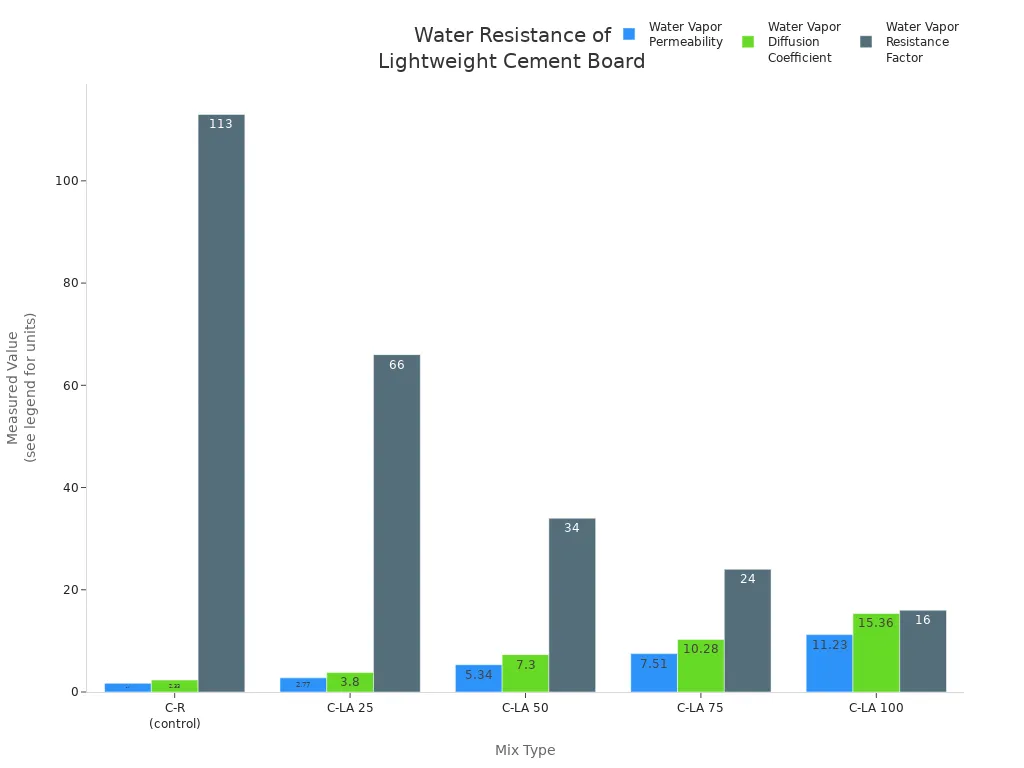

Lab tests also show that lightweight cement board with more lightweight aggregate lets water vapor pass through more easily. This helps prevent moisture from getting trapped inside walls. You can see the results in the chart below:

Tip: For the best mold resistance, always use a waterproof membrane during installation.

Handling and Installation

You will find the installation process for lightweight cement board simple and quick. The board is lighter than regular cement board, so you can carry and cut it with less effort. To get the best results, follow these steps:

Measure carefully before cutting to reduce waste and get a good fit.

Use the right thinset adhesive on top of the board for tile installation.

Pick the correct fasteners, like cement board screws, for strong holding power.

Stagger the seams so four corners do not meet, which keeps the board strong.

Manufacturers recommend installing lightweight cement board over a layer of thinset and using screws made for the product. This keeps your warranty safe and makes sure the board stays strong. Some brands even let you skip extra layers, saving you time during installation. You can finish your installation process faster and with less hassle.

Note: Always follow the manufacturer’s instructions for installation to keep the strength and durability of your project.

Lightweight Cement Panels & Applications

Interior Uses

You will find lightweight cement panels in many interior spaces. These panels work well in both homes and commercial buildings. Here are some common uses:

Sauna and steam rooms

Heat shields behind stoves or fireplaces

Kitchen backsplashes and walls

Fireplace surrounds

Floors in bathrooms, kitchens, and laundry rooms

Accent walls for design features

Lightweight cement panels make your job easier because they are simple to carry and install. You can use them for partition walls and ceilings. These panels reduce the load on your building’s structure, which is helpful for ceilings and upper floors. They also resist fire and mold, making your spaces safer. You will notice that these panels help keep rooms quieter because they block sound well. Their long lifespan and low maintenance needs make them a smart choice for many interior applications.

Tip: Choose lightweight cement panels for wet areas like bathrooms and kitchens to prevent mold and water damage.

Exterior Uses

Lightweight cement panels also work well outside. You can use them for cladding and facade systems on buildings. These panels protect your building from rain, wind, and sun. They are part of rainscreen systems that keep water out and let air flow behind the panels. This helps stop mold and keeps your building dry.

You will see lightweight cement panels on modern buildings because they look good and last a long time. They come in many colors and textures, so you can match your design. These panels resist fire and mold, but you should always use a waterproof membrane for extra protection. Avoid placing them in direct contact with the ground to prevent water from soaking in. With the right installation, lightweight cement panels handle weather changes and stay strong for years.

Feature | Benefit for Exterior Use |

|---|---|

Stops fungus and mold growth | |

Fire rating (Class A) | Increases building safety |

Design options | Many colors and textures |

Durability | Handles rain, sun, and wind |

Tile Substrates

Lightweight cement panels are one of the best choices for tile substrates. You can use them under tile in bathrooms, kitchens, and laundry rooms. These panels give you a flat, stable surface that does not bend or warp. This helps prevent tiles from cracking or coming loose.

You will find that lightweight cement panels are easy to cut and install. They work on walls, floors, and even countertops. The panels resist water, so you do not have to worry about mold or damage in wet areas. For best results, follow these steps:

Make sure the surface is clean and level.

Cut the panels to fit your space.

Attach panels with screws and washers, keeping them spaced correctly.

Cover all joints with mesh tape and waterproof membrane.

Use a good tile adhesive and grout to finish the job.

These steps help you create a strong, long-lasting tile surface. Lightweight cement panels make tile installation faster and more reliable, which is why they are a top pick for both professionals and DIY projects.

Comparing Lightweight Cement Board and Alternatives

Lightweight Cement Board vs. Lightweight MgO Board

Lightweight Cement Board vs. Lightweight MgO Board

When you look at lightweight cement board and lightweight mgo board, you see they are different. Lightweight cement board is made with cement and fibers. Sometimes, it has polystyrene beads inside. Lightweight mgo board uses magnesium oxide, which is a natural mineral. This makes it lighter and easier to carry.

Here is a table that shows the main differences:

Aspect | Lightweight Cement Board | Lightweight MgO Board |

|---|---|---|

Base Material | Cement and fibers | Magnesium oxide (natural mineral) |

Weight | Heavier | Lighter and easier to handle |

Fire Resistance | Good | Excellent |

Moisture Resistance | Needs sealing | Highly resistant |

Environmental Impact | Less eco-friendly | Eco-friendly |

Durability | Strong but may crack | Very durable and impact resistant |

Installation Ease | More effort due to weight | Easier due to lighter weight |

Cost | Cheaper upfront | Higher initial cost but longer-lasting |

Lightweight mgo board is better at stopping fire and water. It can take heat up to 1200°C and does not burn or make toxic smoke. Lightweight cement board is strong but can swell or get weak if it stays wet. You often need to seal it in very wet places.

Lightweight Cement Panels vs. Lightweight Concrete Panels

You might wonder how lightweight cement panels are different from lightweight concrete panels. Lightweight cement panels are much lighter. You do not need big machines to move them. You can put them in place faster and with less work. These panels often have grooves and tongue joints. This helps you fit them together easily. You make less mess and spend less time cleaning up.

Lightweight concrete panels are also easy to move and use. You can add mineral wool insulation between them to keep heat in or out. Both types need less support from steel or concrete. This helps you save money when building.

Cost and Performance

When you check the price of lightweight cement board, you see it costs less at first. The price is about $5.38 to $10.76 for each square meter. Lightweight mgo board costs more, about $16.15 to $37.67 per square meter. But lightweight mgo board is easier to install, so you pay less for labor. It also lasts longer and does not need much fixing, so you save money later.

Lightweight concrete panels cost about $14 per square meter in some places. You do not need heavy tools to put them in, so you save time and money. Both lightweight cement board and lightweight mgo board last a long time. But lightweight mgo board is best for fire and water safety.

Tip: If you want to spend less at first, pick lightweight cement board. If you want less work later and better fire safety, lightweight mgo board is a good choice.

When you pick lightweight cement board, you get many good things.

These boards are strong and last a long time.

They are great for places that get wet.

They are also better for the environment.

Tip: Make sure the board fits your project. Think about if you need it to stop water, last long, or be easy to use. In wet places, always use sealants or membranes. For more warmth, use foam or fiberglass with the board.

If you want to know more, ask local stores or building pros.

FAQ

What is the main difference between lightweight cement board and lightweight mgo board?

You will notice that lightweight mgo board uses magnesium oxide as its base. Lightweight cement board uses cement and fibers. Lightweight mgo board feels lighter and resists fire better. You can use lightweight mgo board where you need extra safety.

Can you use lightweight mgo board in wet areas like bathrooms?

Yes, you can use lightweight mgo board in wet places. This board does not soak up water. You will see that lightweight mgo board stays strong and does not grow mold. Many builders pick lightweight mgo board for showers and kitchens.

Is lightweight mgo board safe for the environment?

You will find that lightweight mgo board is more eco-friendly than many other boards. Factories make lightweight mgo board from natural minerals. This means you use fewer chemicals. Lightweight mgo board also lasts a long time, so you do not need to replace it often.

How do you install lightweight mgo board?

You can cut lightweight mgo board with simple tools. You screw lightweight mgo board to the wall or floor frame. Always follow the instructions from the maker. Lightweight mgo board does not need special glue. You can finish your job quickly.

Does lightweight mgo board cost more than other boards?

Lightweight mgo board usually costs more at first. You may pay less later because lightweight mgo board lasts longer and needs less fixing. Many people choose lightweight mgo board for its strength and safety, even if it costs more at the start.

Lightweight Cement Board vs. Lightweight MgO Board

Lightweight Cement Board vs. Lightweight MgO Board