19 Feb What Are Structural Insulated Panels and Their Types

Table of Contents

Structural insulated panels (SIPs) are advanced building materials designed to improve construction efficiency. These panels consist of an insulating foam core sandwiched between two rigid structural facings, creating a lightweight yet durable component. You’ll find SIPs particularly valuable for their ability to enhance energy efficiency. Compared to traditional materials, they provide 100% greater R-values for the same thickness and reduce air infiltration by 12 times. This means homes built with SIPs require smaller HVAC systems, cutting heating and cooling costs significantly.

The adoption of structural insulated panels options is growing rapidly. The global market, valued at $11.8 billion in 2023, is projected to reach $19.6 billion by 2032, with a CAGR of 5.9%. These panels also align with sustainable construction practices, offering eco-friendly materials and reducing energy consumption. By choosing SIPs, you can achieve faster construction times, lower operational costs, and a more sustainable building solution.

Structural Insulated Panels Options and Their Types

Expanded Polystyrene (EPS) Panels

Features of EPS Panels

EPS panels are among the most common structural insulated panels options available today. These panels feature a lightweight core made of expanded polystyrene foam, which is sandwiched between two rigid facings. You’ll find them easy to handle and cost-effective compared to other types. Their workability allows you to cut and shape them on-site, making them suitable for various applications in residential construction. However, EPS panels may melt under high heat, forming a hard skin, which can limit their fire resistance.

R-value and Thermal Performance

EPS panels deliver high r-values, ensuring excellent thermal insulation. However, their r-value can decrease slightly over time. This happens due to the natural aging of the foam, but the panels still maintain good energy efficiency. If you’re looking for structural insulated panels options that balance cost and performance, EPS panels are a reliable choice.

Polyurethane (PUR) Panels

Features of PUR Panels

Polyurethane panels stand out for their versatility and durability. These panels come pre-cut, which saves you time during installation. They are ideal for walls, roofs, and partitions in both residential and commercial buildings. Their non-sagging properties ensure long-term performance, even in demanding environments.

Moisture Resistance and Insulation Properties

PUR panels excel in moisture resistance, making them suitable for areas prone to dampness. They also offer a higher initial r-value compared to EPS panels, providing superior insulation. Over time, the r-value may decrease slightly due to thermal drift, but the airtight construction of SIPs ensures consistent energy efficiency. These panels are particularly effective in industries like food processing and pharmaceuticals, where maintaining temperature zones is critical.

Compressed Straw-Core Panels

Features of Straw-Core Panels

Compressed straw-core panels are an eco-friendly alternative to traditional SIPs. These panels use agricultural waste, such as straw, to create a dense core. You’ll appreciate their natural fire resistance and soundproofing capabilities. They are also lightweight, making them easy to transport and install.

Sustainability and Environmental Benefits

Straw-core panels contribute significantly to sustainable construction practices. By utilizing locally sourced agricultural waste, they reduce the embodied carbon emissions associated with building materials. This makes them an excellent choice for low-carbon building projects. If you prioritize environmental sustainability, these panels align perfectly with your goals.

Magnesium Oxide Panles( mgo board)

Features of Magnesium Oxide (MgO) Panels

Magnesium Oxide (MgO) panels offer unique properties that make them a standout choice among structural insulated panels. These panels are known for their excellent fireproof qualities, making them a safe option for construction. They are incombustible and achieve a fire rating class of A1, ensuring superior fire resistance. You’ll also find them lighter than other cement-based boards, reducing the overall weight of your building materials by 20 to 30 percent.

MgO panels resist mold, mildew, and fungus, which prevents rot and allergens from forming. This feature makes them ideal for damp or humid environments. Their durability and impact resistance ensure long-lasting performance, even under challenging conditions. Additionally, these panels are non-toxic and asbestos-free, contributing to a healthier indoor environment.

| Property | Description |

|---|---|

| Fire Resistance | Incombustible with a fire rating class: A1 |

| Lightweight | 20 to 30 percent lighter than cement-based boards |

| Mold Resistance | Non-toxic, mold and asbestos-free |

| Eco-friendliness | 100% recyclable |

| Durability | Highly durable and impact resistant |

Sustainability and Environmental Benefits

MgO panels stand out for their eco-friendly production process. They are made from natural magnesium sulfate, which reduces the environmental impact compared to other materials. During production, these panels sequester carbon dioxide, actively reducing greenhouse gases. This process also consumes less energy, making them more sustainable than traditional building materials.

You’ll appreciate that MgO panels produce negligible toxic off-gassing, ensuring a safer environment for occupants. They are also landfill-friendly and 100% recyclable, which minimizes waste. Compared to other structural insulated panels, MgO panels align better with sustainable construction practices.

| Feature | Magnesium Oxide Panels | Other Building Materials |

|---|---|---|

| Made from Natural Materials | Yes | Varies |

| Toxic Off-Gassing | Negligible | Possible |

| Landfill Friendly | Yes | Varies |

| CO2 Sequestration | Yes | No |

| Energy Consumption | Lower | Higher |

If you’re looking for SIPs that combine durability, safety, and sustainability, MgO panels are an excellent choice. Their unique features and environmental benefits make them a valuable addition to modern construction projects.

Features and Applications of Structural Insulated Panels

Key Features of SIPs

High R-values and Energy Efficiency

SIPs excel in energy efficiency due to their high R-values, which measure thermal resistance. These panels minimize heat transfer, keeping your building warm in winter and cool in summer. Compared to traditional materials, SIPs offer superior insulation, reducing energy consumption and lowering utility bills. Their airtight construction also prevents drafts, ensuring consistent indoor temperatures.

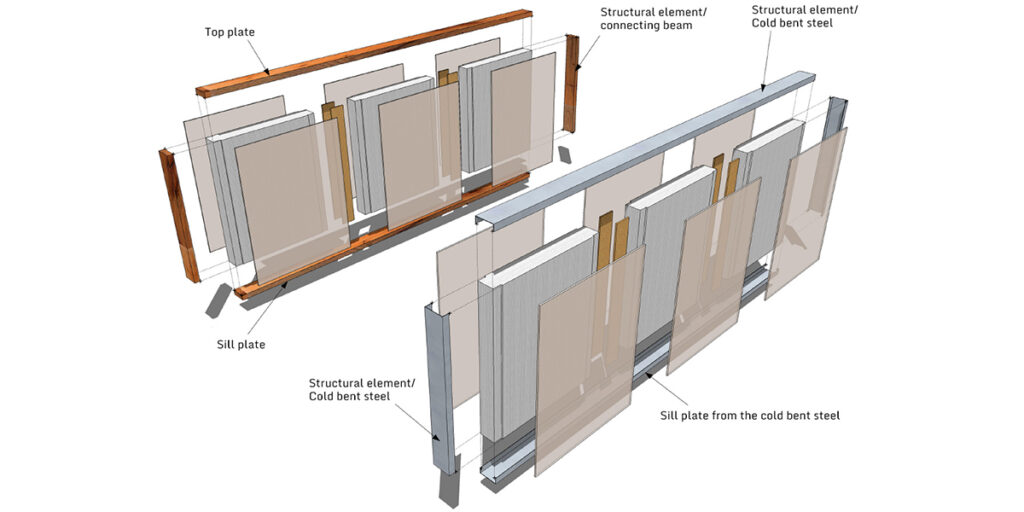

Structural Integrity and Design Flexibility

SIPs provide exceptional structural integrity with their high strength-to-weight ratio. This makes them a reliable choice for both residential and commercial projects. You can use SIPs in various dimensions and thicknesses, ranging from 4 to 8 inches, to suit your design needs. Their versatility allows you to create unique architectural designs without compromising strength or durability.

Applications in Residential Construction

Use in Walls, Roofs, and Floors

SIPs are widely used in residential construction for walls, roofs, and floors. These panels simplify the building process by combining insulation and structural support in one product. For walls, they provide efficient insulation and quick installation. Roofs benefit from their energy efficiency and design flexibility, while floors align with the pace of modern construction due to their prefabricated nature. Whether you’re building a new home or renovating, SIPs enhance durability and energy performance.

| Application Type | Benefits |

|---|---|

| Walls | Efficient insulation, quick installation |

| Roofs | Energy efficiency, design flexibility |

| Floors | Prefabricated nature aligns with construction pace |

Applications in Commercial and Industrial Construction

Use in Refrigeration and Cold Storage

SIPs play a critical role in refrigeration and cold storage facilities. Their high thermal efficiency ensures consistent temperature control, making them ideal for food processing plants, warehouses, and pharmaceutical storage. You’ll also find them in refrigerated trucks, where they maintain the required temperature for transporting sensitive items like medicines and perishable goods.

Use in Modular and Prefabricated Buildings

Modular and prefabricated buildings benefit greatly from SIPs. These panels are used in commercial spaces with high machine-generated heat, medical storage facilities, and large-scale cooling systems like walk-in freezers. Warehouses storing food, electronics, and other temperature-sensitive products also rely on SIPs for maintaining cold environments. Their prefabricated nature speeds up construction while ensuring high performance.

| Application Type | Description |

|---|---|

| Commercial Buildings | Used for efficient temperature control in environments with high machine-generated heat. |

| Medical Storage Facilities | Essential for maintaining the required temperature for medicines and medical items. |

| Large-Scale Cooling Systems | Utilized in refrigerators and walk-in freezers for temperature maintenance in various facilities. |

| Warehouses | Helps maintain cold temperatures for storing food, electronics, and other temperature-sensitive items. |

Specialized Applications

Use in Pharmaceutical Facilities

Structural insulated panels (SIPs) play a vital role in pharmaceutical facilities where precise temperature control is essential. You can use SIPs to construct clean rooms and cold rooms, which are critical for maintaining sterile environments and storing temperature-sensitive medicines. Polyurethane insulation panels, in particular, excel in these applications due to their high thermal efficiency and moisture resistance.

In pharmaceutical manufacturing, maintaining consistent internal temperatures is non-negotiable. SIPs help you achieve this by providing airtight insulation that minimizes heat transfer. These panels are also used in refrigerated trucks to transport drugs that require specific temperature ranges. Additionally, insulated wall panels create controlled temperature zones within factories and warehouses, ensuring the integrity of medical products.

The benefits of SIPs in pharmaceutical settings extend beyond temperature control. Their prefabricated nature speeds up construction, reducing downtime for facility upgrades. You’ll also find that their durability and resistance to mold and mildew contribute to a cleaner, safer environment for drug production and storage.

Retrofitting Existing Buildings

Retrofitting existing buildings with SIPs offers a practical way to improve energy efficiency and structural performance. While the initial material costs may seem higher—ranging from $5 to $8 per square foot for a six-inch wall panel—you’ll save significantly on labor and long-term energy expenses. SIPs reduce framing labor by up to 55% and cut onsite construction time by nearly 50%. This means faster project completion and lower overall labor costs.

When you retrofit with SIPs, you also minimize waste. These panels are prefabricated to precise dimensions, nearly eliminating onsite material scraps. This reduces disposal costs and aligns with sustainable building practices. Over time, the high insulation values of SIPs lower heating and cooling costs, making them a cost-effective choice for retrofitting projects.

SIPs are particularly effective for upgrading older buildings with poor insulation. By replacing traditional materials with SIPs, you can enhance thermal performance and reduce air leakage. This not only improves indoor comfort but also lowers your building’s carbon footprint. Retrofitting with SIPs combines energy savings, faster construction, and environmental benefits into one efficient solution.

Benefits of Structural Insulated Panels

Energy Efficiency and Cost Savings

Reduced Heating and Cooling Costs

Structural insulated panels offer exceptional energy efficiency compared to traditional insulation methods. These high-performance insulating panels reduce heating and cooling energy demands by at least 60%. Their tight building envelope minimizes air infiltration and heat loss, ensuring your home stays comfortable year-round. This efficiency allows you to install smaller, less expensive HVAC systems, further lowering costs.

SIPs also provide higher R-values, such as 22.3 compared to 19 for conventional materials, delivering excellent thermal insulation. A case study revealed that a 1,000-square-foot home built with SIPs saved over $14,000 in HVAC and utility expenses over ten years. By choosing SIPs, you benefit from reduced energy bills and a quick payback period for the embodied energy, typically within three to five years.

Durability and Strength

Resistance to Structural Stress and Longevity

SIPs are a high-performance building system designed to withstand structural stress while maintaining durability. Their foam insulation core, sandwiched between OSB sheathing panels, provides high strength and thermal performance. This makes them ideal for both residential and commercial applications.

To ensure longevity, you should use continuous foam sealants, gaskets, and SIP tapes for airtight seals. Proper installation, including water-resistant barriers, prevents moisture damage and extends the lifespan of your panels. SIPs also resist warping and sagging, making them a reliable choice for high-performance construction systems.

Environmental Sustainability

Reduced Waste and Carbon Footprint

SIPs contribute significantly to sustainable construction. Their factory fabrication process optimizes material use, reducing jobsite waste by an average of 30%. This efficient production method minimizes landfill waste and aligns with eco-friendly practices.

By improving energy efficiency, SIPs prevent greenhouse gas emissions, lowering the environmental impact of your building. These panels offer energy savings that are 9.9 times greater than the energy invested in their production. Additionally, SIPs reduce framing labor by up to 55% and cut construction time by 50%, further decreasing the carbon footprint of your project.

When you choose SIPs, you’re not just building energy-efficient walls—you’re investing in a high-performance construction system that supports sustainability and reduces long-term costs.

Faster Construction Times

Prefabrication and Ease of Installation

Structural insulated panels (SIPs) revolutionize construction by significantly reducing building time. These panels are prefabricated in factories, ensuring precise dimensions and quality control. Once delivered to the site, they allow for rapid assembly, minimizing delays caused by weather or material inconsistencies. Prefabrication eliminates the need for separate insulation and framing steps, streamlining the entire process.

Using SIPs for framing a house typically takes about eight days, compared to 12 days with traditional stick framing. This efficiency stems from their dual functionality as both structural and insulating components. You save time because SIPs arrive ready to install, reducing the need for on-site adjustments.

Research shows that SIPs cut labor hours for framing by 55% to 66%. This reduction translates to faster project completion and lower labor costs. For example, framing with SIPs requires fewer workers, allowing you to allocate resources to other tasks. The panels’ lightweight nature also simplifies handling, further speeding up installation.

| Advantage | Description |

|---|---|

| Rapid Assembly | SIPs are prefabricated off-site, enabling quick on-site assembly. |

| Reduced Labor | Labor hours for framing decrease by 55% to 66%, accelerating construction. |

| Shorter Framing Time | Framing a house with SIPs takes about eight days, compared to 12 days for traditional methods. |

The ease of installation extends beyond framing. SIPs simplify the construction of walls, roofs, and floors, making them ideal for residential and commercial projects. Their sandwich panel design integrates insulation and structure into one product, reducing the need for multiple materials. This integration not only saves time but also ensures consistent quality across the building.

By choosing SIPs, you benefit from faster construction times, reduced labor costs, and a more efficient building process. Whether you’re constructing a home or a commercial facility, SIPs offer a practical solution for meeting tight deadlines without compromising quality.

Drawbacks of Structural Insulated Panels

Higher Initial Costs

Comparison with Traditional Materials

When comparing structural insulated panels to traditional materials, you’ll notice their higher initial costs. Several factors contribute to this.

- The advanced technology used in manufacturing SIPs increases production expenses.

- SIPs integrate insulation, structural components, and sometimes exterior finishes, making them more comprehensive but also pricier.

- The upfront cost reflects the multifaceted nature of these panels, which combine multiple building functions into one product.

Although the initial investment may seem steep, SIPs often pay off in the long run through energy savings and reduced labor costs. However, for budget-constrained projects, the higher upfront expense can pose a challenge.

Susceptibility to Water Damage

Importance of Proper Installation and Maintenance

Water damage remains a significant concern for SIPs. When exposed to moisture, SIP walls made with OSB or plywood can deteriorate and rot. This compromises their structural integrity. Additionally, moisture can lead to mold growth, which affects indoor air quality.

To mitigate these issues, you should prioritize proper installation and maintenance. Using moisture-resistant materials and ensuring adequate ventilation can help protect SIPs from water-related problems. Applying water-resistant barriers during construction also prevents moisture infiltration. By taking these precautions, you can extend the lifespan of your panels and maintain their performance.

Limited Design Flexibility

Challenges in Customization for Complex Designs

SIPs can limit your design options, especially for complex architectural projects. Their prefabricated nature restricts customization, making it difficult to meet unique structural needs. Larger panels often require specialized equipment like cranes or forklifts, which increases costs and complicates installation.

The size and shape of SIPs can also constrain architectural creativity. This may result in boxy structures that lack aesthetic appeal. For intricate designs, traditional materials may offer more flexibility. Despite these challenges, SIPs remain a practical choice for straightforward projects where efficiency and energy performance take precedence.

Note: While SIPs excel in many areas, their drawbacks—higher costs, water susceptibility, and limited design flexibility—highlight the importance of evaluating your project’s specific needs before choosing them.

Structural insulated panels (SIPs) offer a transformative approach to modern construction. You’ve learned about their diverse types, including EPS, PUR, straw-core, and MgO panels, each with unique features and benefits. SIPs excel in energy efficiency, durability, and sustainability while reducing waste and carbon emissions. However, challenges like higher initial costs and moisture management require careful planning.

| Aspect | Description | Impact on Growth |

|---|---|---|

| Sustainable Construction | SIPs are sustainable due to resource-efficient manufacturing and recyclability. | Growing environmental consciousness and regulatory support for sustainable practices. |

| Energy Efficiency | Airtight and insulated building envelope reduces energy consumption. | Sets a new standard for sustainable construction, curbing carbon emissions. |

By choosing SIPs, you can revolutionize your projects with faster construction times and healthier indoor environments. Explore these innovative panels to build smarter, greener, and more efficient structures.